Tool shank inspection gauge

A tool handle and measuring tool technology, which is applied in the field of tool handle detection and measuring tools, can solve the problem that small-diameter tool handle detection tools are not suitable for mass inspection, and achieve the effect of stable, accurate and high-efficiency detection dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

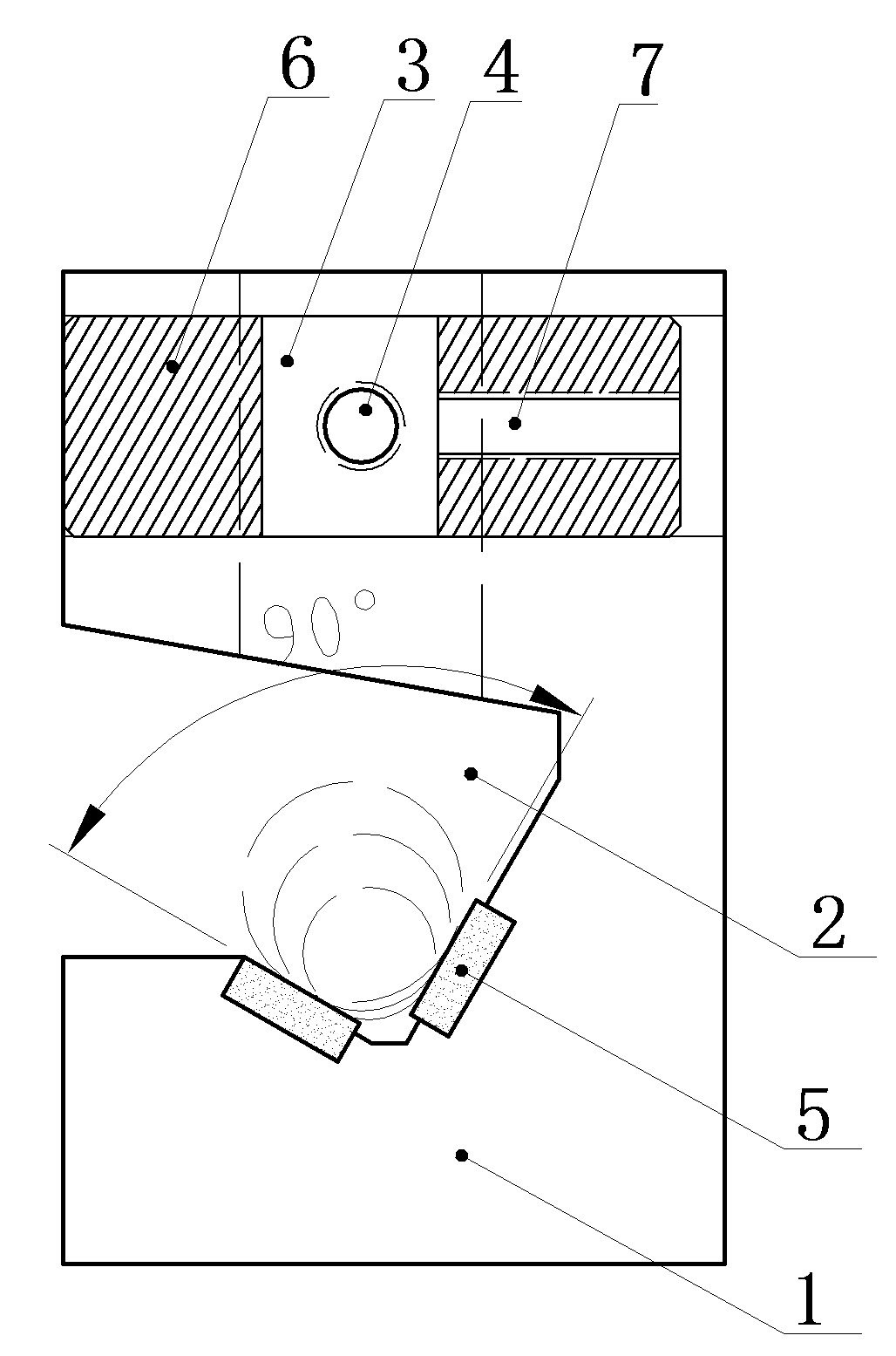

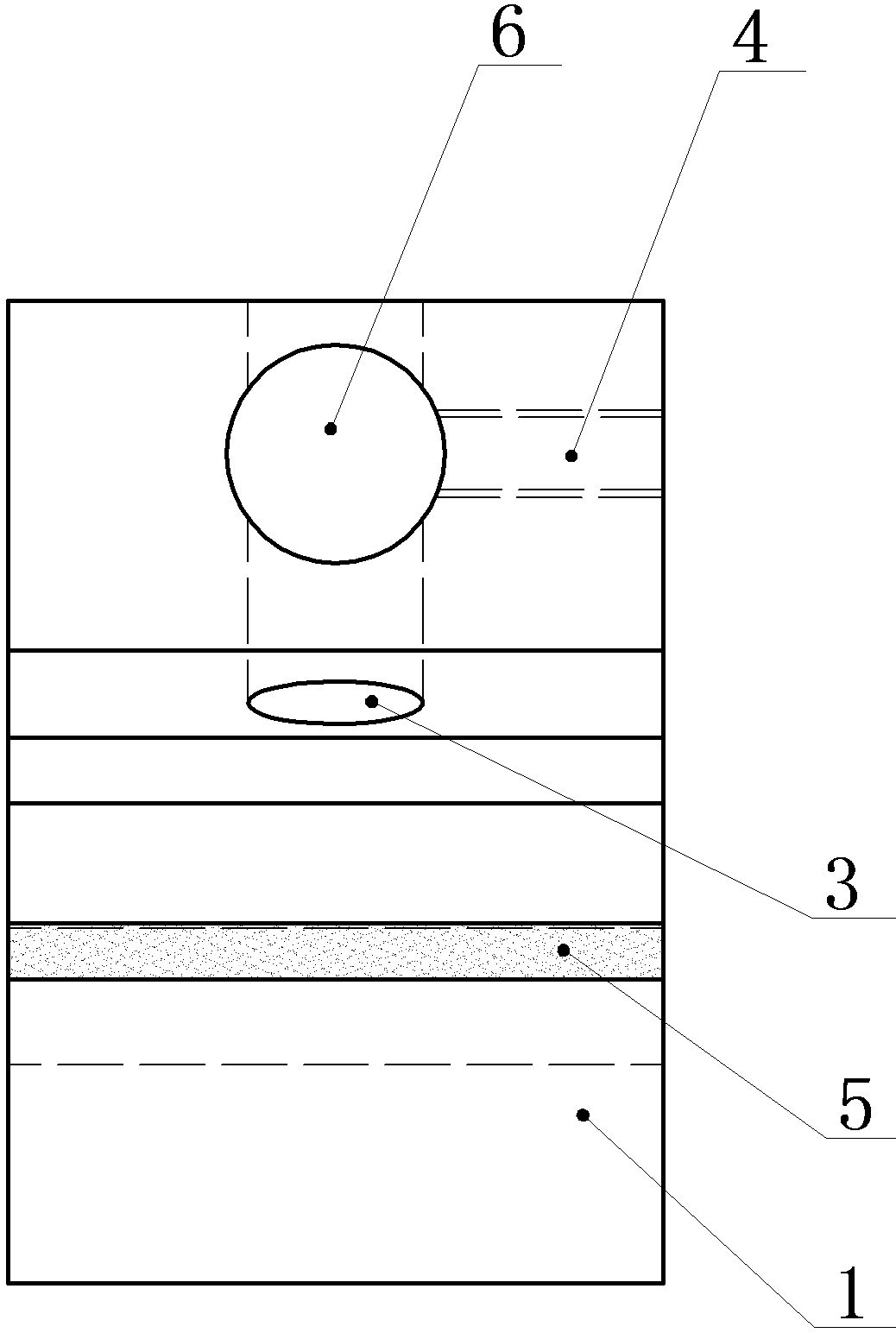

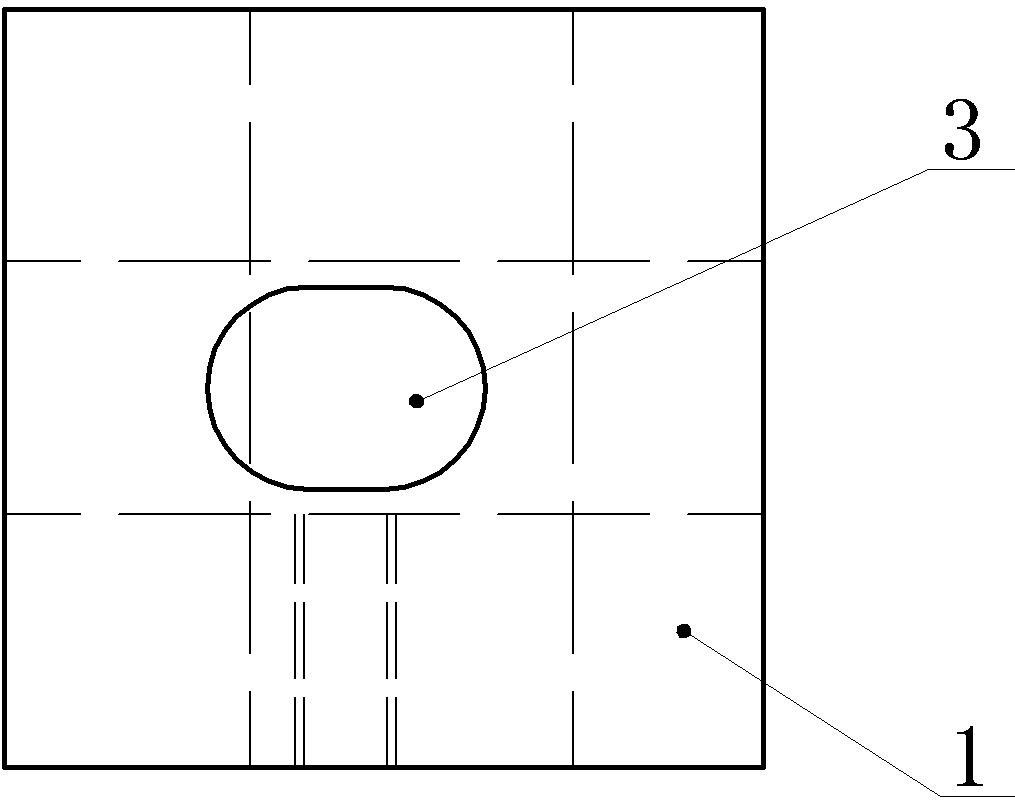

[0015] Example 1: figure 1 , figure 2 , image 3 and Figure 4 shows a tool handle detection measuring tool, the measuring tool has a rectangular structure, a horizontal and longitudinal tool handle installation hole (detection groove) 2 is provided in the middle of the measurement tool 1, and an opening is provided on one side of the tool handle installation hole 2 , The handle is easy to load and take out. Both sides of the bottom of the handle mounting hole 2 are respectively fixed with a wear-resistant positioning block 5, which is preferably a diamond wear-resistant positioning block, and repeated positioning does not affect the size.

[0016] A horizontal and transverse pin hole is provided on the upper side of the knife handle installation hole 2, and a center adjustment pin 6 is matched and installed in the pin hole (the center adjustment pin here can also appear in other forms, such as using an adjustment block), in this embodiment The cross-section of the pin ho...

Embodiment 2

[0017] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that in this embodiment, the pin hole and the central adjustment pin are designed to match, and its cross section is square or regular hexagonal .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com