Toroidal fissured rock sample, MHC coupled seepage experimental device of sample and use method of device

A technology for rock specimens and experimental devices, which is used in measurement devices, preparation of test samples, permeability/surface area analysis, etc. and other problems, to achieve the effect of enhancing the adaptability of test conditions, low cost, and simple and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

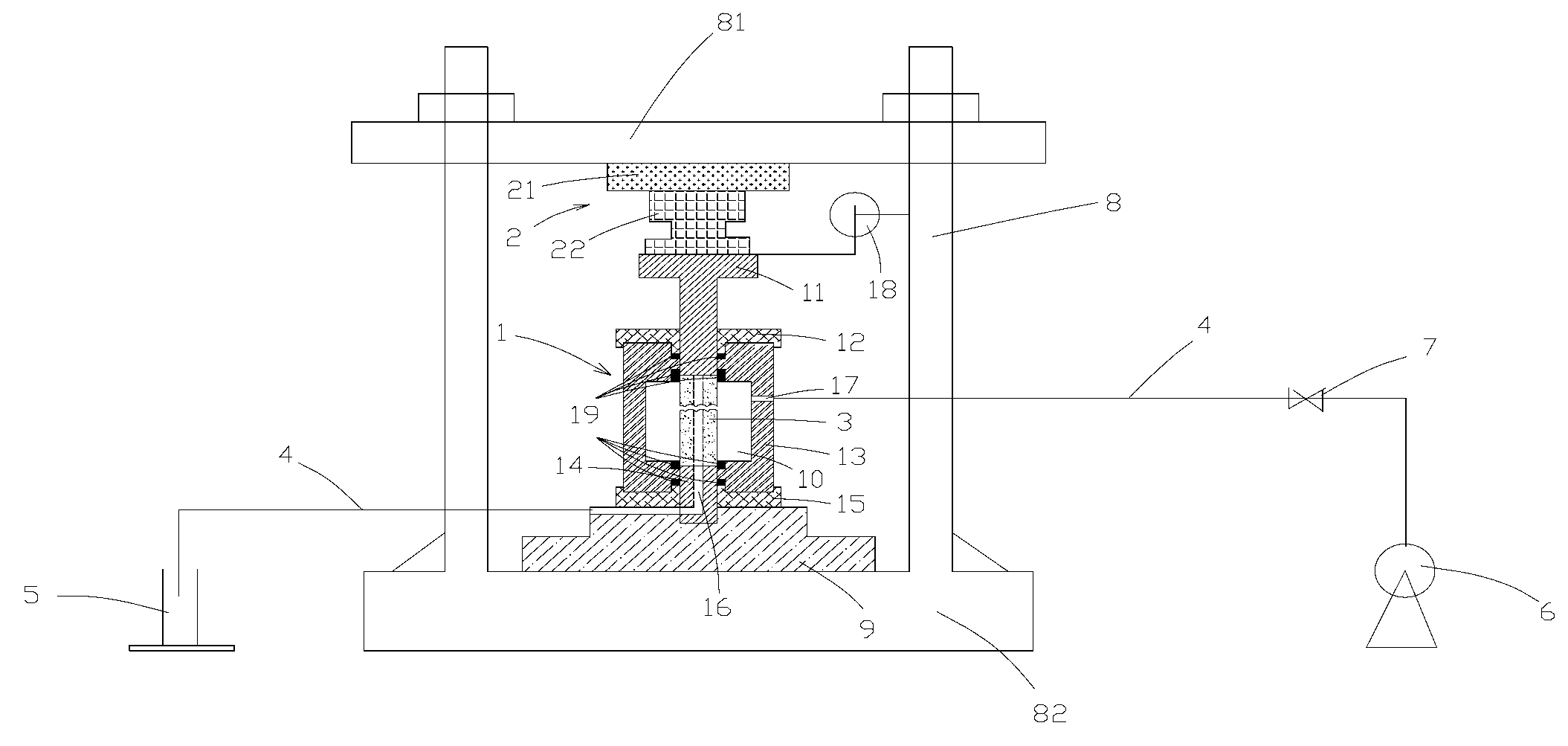

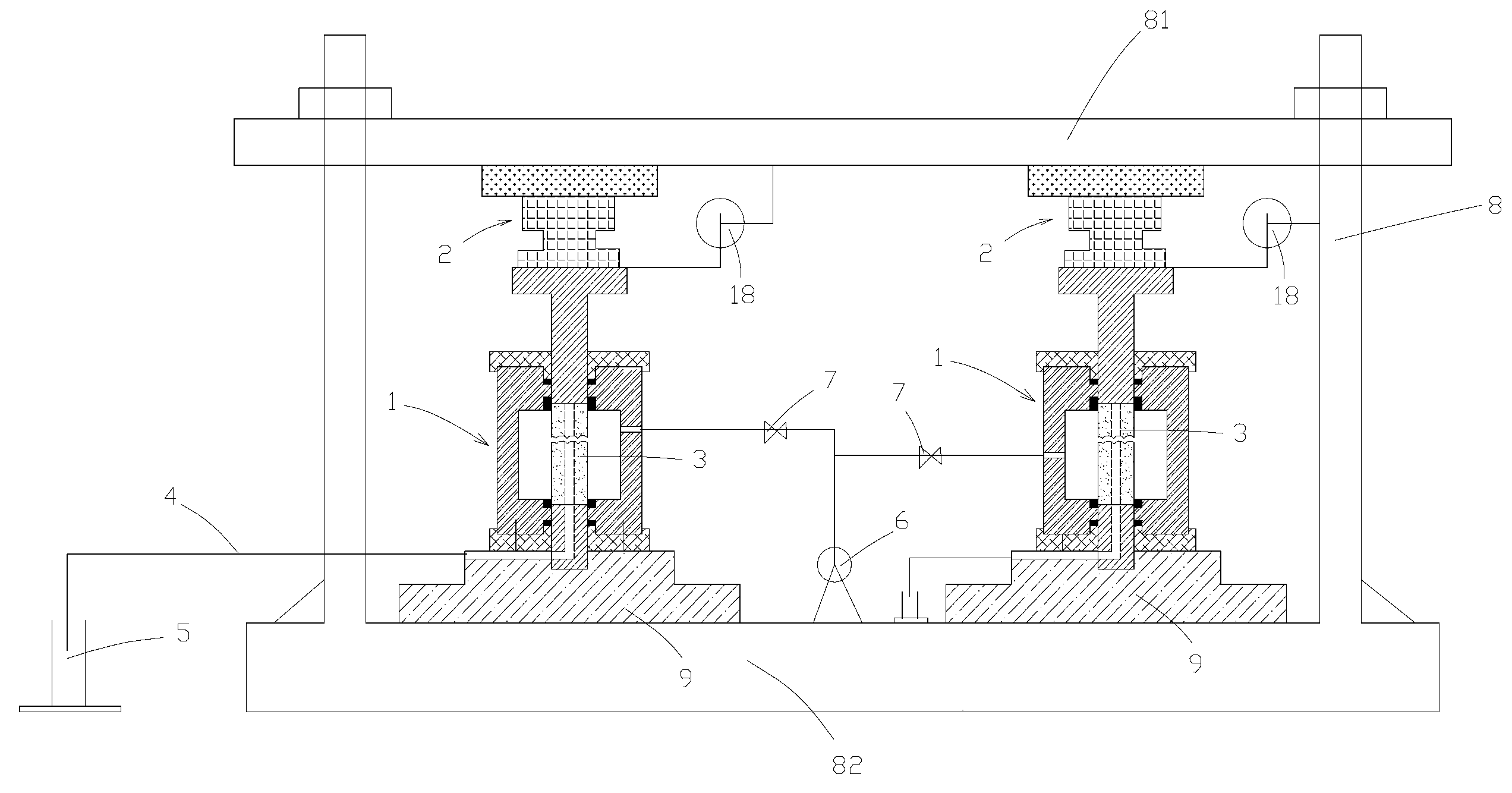

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

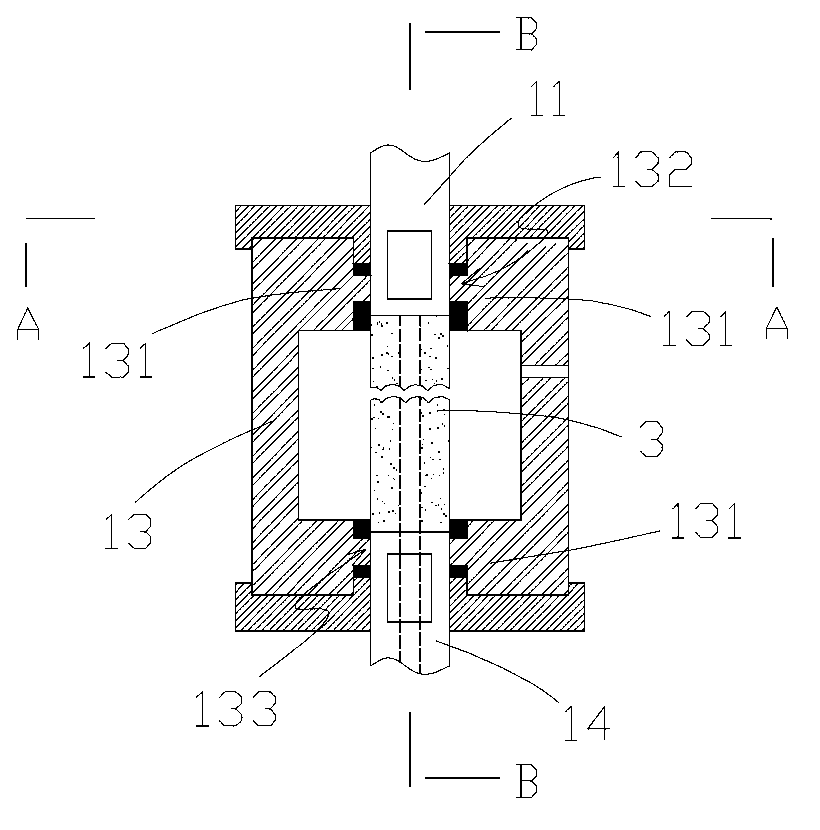

[0045] Such as Figure 6-7 Shown: A circumferentially fractured rock specimen with:

[0046] The cylindrical test piece main body 3 has an axial through hole, and the center of the through hole coincides with the center of the test piece main body 3 .

[0047] In order to ensure the thickness of the side wall of the rock test piece, the aperture of the through hole is 1 / 5 of the outside of the test piece main body 3. During the experiment, the outer diameter of the test piece main body 3 was processed to 5 cm, and the diameter of the through hole was 1 cm.

[0048] The formation of the radial through-crack: firstly, the main body 3 of the test piece is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com