Full-fiber sensing probe winding device and winding method

A technology of sensing probe and winding method, which is applied in digital control, electrical program control, non-electric variable control, etc., can solve the problem of insufficient attention to the winding device method of optical fiber sensing probe, unstable winding speed, and twisted optical fiber And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

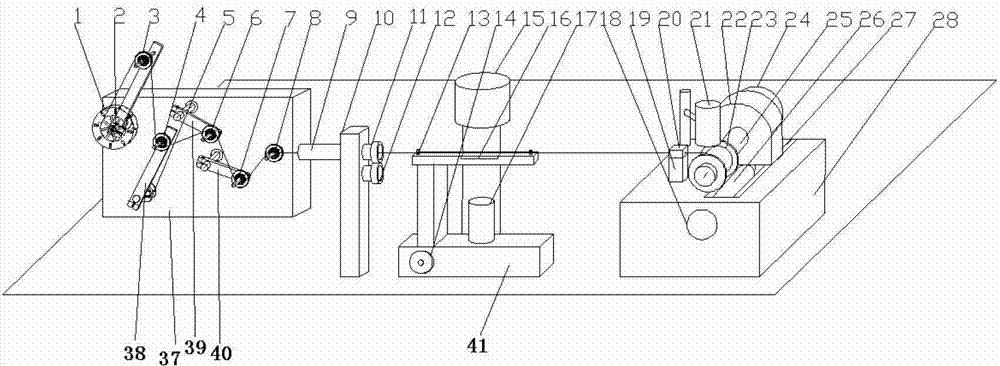

[0038] Such as figure 1 A schematic structural diagram of a winding device for an all-optical sensor probe for realizing the method of the present invention. In the specific example shown in the figure, the structure of the winding device for the all-optical sensor probe includes a tension control system, a precision cable winding system, an optical fiber state adjustment system, and an optical fiber glue coating control system. The specific functions are as follows:

[0039] (1) Tension control system

[0040] The tension control system includes tension sensor 2 and amplifier circuit, tension control motor 2, dance wheel 4, preparation ring bracket 1, guide pulley 5, adjusting wheel 6 and adjusting wheel 7, A\D sampling and feedback control circuit part. During the fiber winding process, the optical fiber is led out from the preparation ring support, passes through the dance wheel, the tension sensor, the adjustment wheel, and the guide pulley 8, and finally the optical fiber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com