Galvanized carbon steel with stainless steel-like finish

一种碳钢、有机物的技术,应用在叠加层的镀覆、制造工具、热浸镀工艺等方向,能够解决影响外观一致性材料耐蚀性、难生产等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

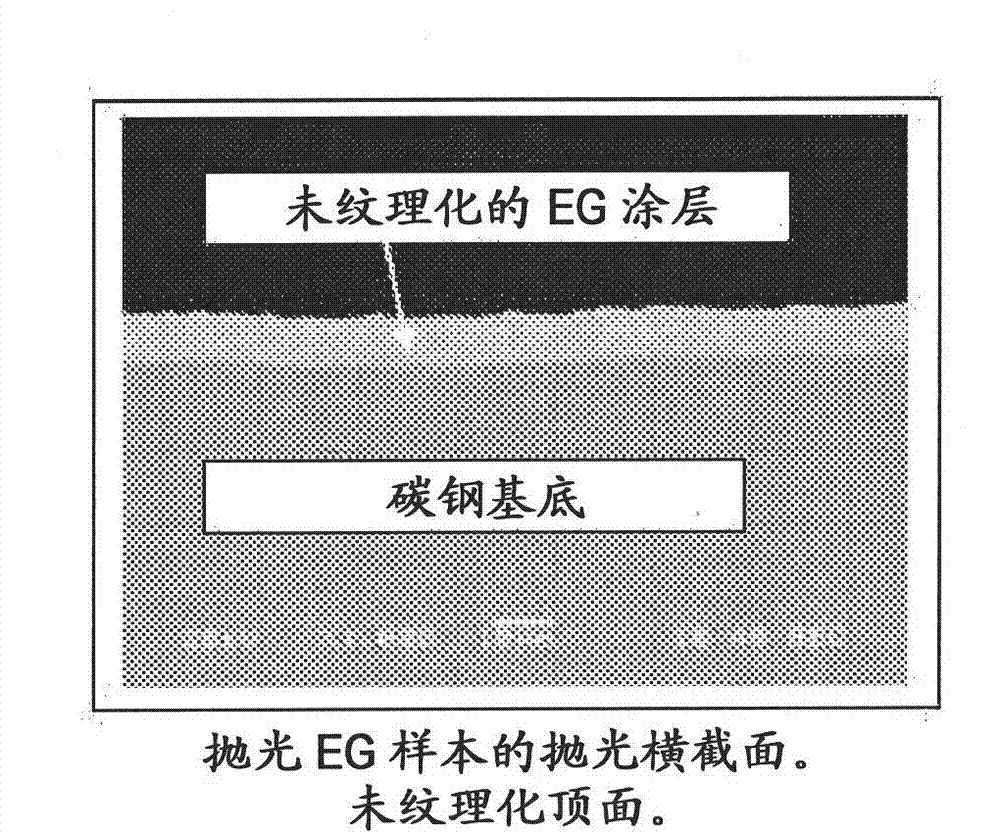

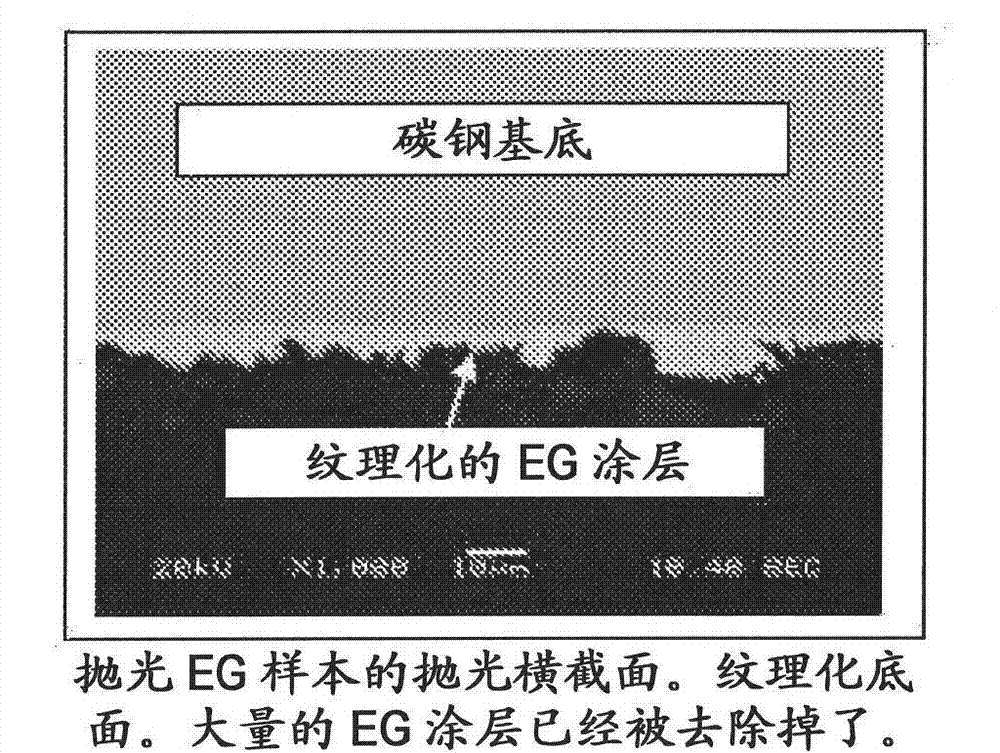

[0029]Electrogalvanized carbon steel strip can be processed on lines for polished stainless steel. The surface texture is obtained by contact with the abrasive belt. Usually texturing is limited to one surface. The speed of the steel belt, the speed of the grinding belt, the pressure applied, the nature and grain size of the abrasive, and the hardness of the material being processed all have an effect on the appearance of the polished product. Due to the softer nature of the zinc surface on electrogalvanized steel compared to stainless steel, adjustments are required to ensure that the zinc coating is not completely removed during polishing. Examination of zinc coating integrity on samples of coils processed in this manner found that approximately 50% of the zinc remained after processing in terms of coating weight. However, cross-sections of the processed material revealed isolated areas where the zinc coating was almost completely removed (Fig. 1). This polished carbon st...

example 2

[0032] A second test was performed using an electrogalvanized carbon steel strip, where the surface was continuously subjected to an abrasive brush type roller, rather than an abrasive belt. This procedure tends to be less aggressive in terms of zinc removal. However, this procedure can result in a visual appearance that deviates from the desired texture associated with typical polished stainless steel (Figure 3). By varying processing conditions such as relative roll and belt speeds, roll pressure, and roll grain size and texture, a more desired appearance can be developed. However, as with other grinding-based processes, there is the same concern that it is difficult to control the amount of zinc removed. Thus, it may be difficult to maintain uniform appearance and corrosion resistance. Visual inspection of the material after processing revealed that the surface texture developed and illustrated in Figure 3 was quite different from polished stainless steel, limiting the ma...

Embodiment 3

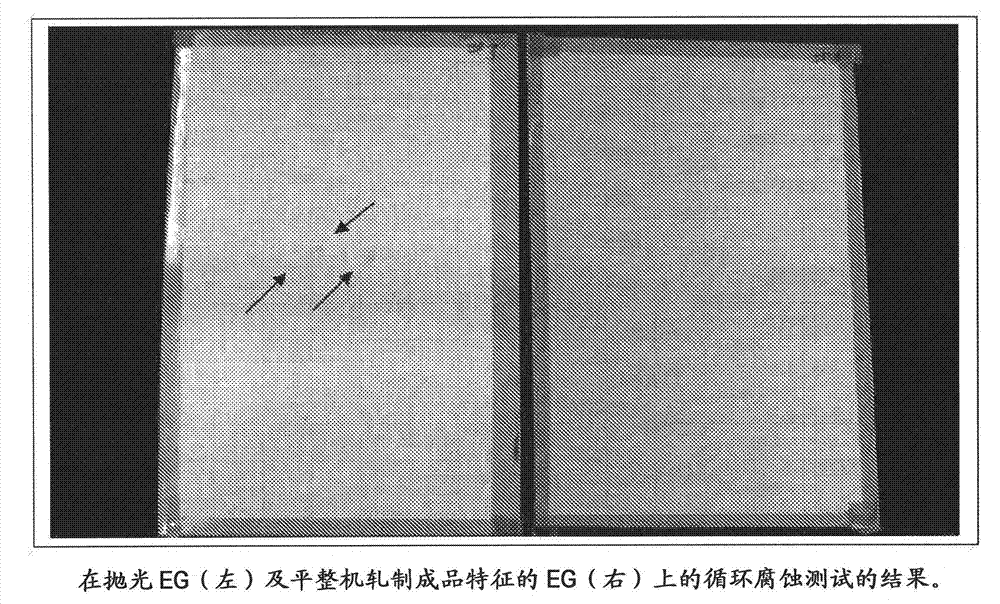

[0034] Performance evaluation tests were performed on samples of electrogalvanized carbon steel coils processed using a skin pass mill and subsequently coated with a clear polymer film. The amount of galvanized coating removed is minimal. The samples were tested for corrosion resistance and formability. the following in Image 6 Corrosion resistance results are shown in .

[0035] Wet / dry cyclic corrosion testing has shown that electrogalvanized steel with rolled texture finish features and organic coatings has less surface pitting than polished 430 stainless steel. Tests of samples without an organic coating also had pitting, but had areas of white rust typical of galvanized steel. The edges of the 4x6 inch samples were taped to eliminate the trimming effect, and the samples were immersed in a 5% saline solution for 15 minutes. The samples were then air dried for 90 minutes and placed in a humidity cabinet at 60°C for approximately 72 hours. The wet / dry portion of the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com