Automatic ventilation device of vegetable greenhouse

A vegetable greenhouse and ventilation device technology, applied in horticulture, greenhouse cultivation, climate change adaptation and other directions, can solve problems such as labor consumption, unfavorable growth of fruits and vegetables, shortening service life, etc., and achieve the effect of saving electric energy, saving manpower and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

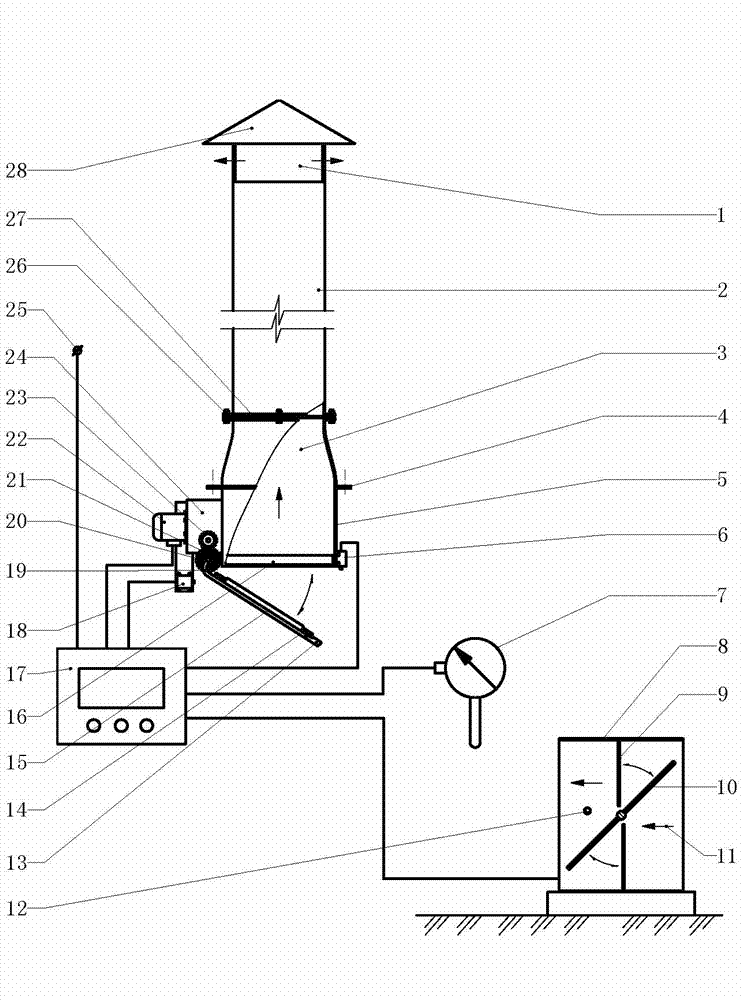

[0013]Embodiment The automatic ventilation device for vegetable greenhouses shown in the drawings is mainly composed of a blower tube (2), a blower assembly (5), a travel switch a (6), a travel switch b (18), a fresh air assembly (8), an electric contact Composed of point thermometer (7), controller (17) and automatic ventilation actuator, wherein, the height of the blower (2) is 3 meters, the puller (2) is a cylindrical structure, and the blower assembly (5) The upper end has a round opening and the lower end has a square opening. There is a connecting flange a (26) at the upper round opening of the blower assembly (5), and a connecting flange b (27) at the lower end of the blower tube (2). Connecting flange a (26) and connecting flange b (27) are connected with bolts; there is a rain cover (28) on the top of the blower (2), and the rain cover (28) passes through the pole and the puller (2) Connect, the space between the rain cover (28) and the blower tube (2) constitutes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com