Nail head assembly of stitching device and sewing cutting device

A suture cutter and stapler technology, which is applied to the staple head assembly of arc suture cutters, or linear suture cutters and linear staplers, can solve the problem of enlarged head structure, poor staple formation, aluminum Insufficient strength of alloy materials, etc., to achieve the effect of reducing the amount of deformation and increasing the strength of the nail head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

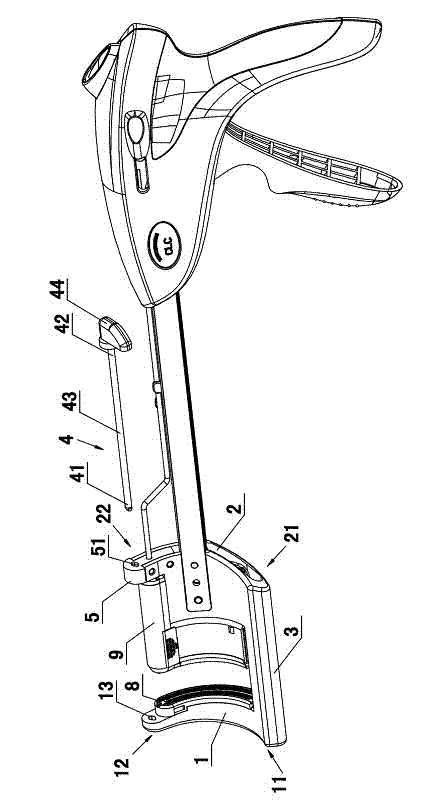

[0036] The invention discloses a nail head assembly, which is suitable for a linear stapler, a linear stapler, or an arc stapler and the like. Because these staplers or seam cutters basically include anvils 8 and staple bins 9 that are relatively parallel to each other.

[0037] like figure 1 As shown, the nail head assembly includes a U-shaped frame, which is arranged in a U-shape with a lateral opening as a whole, and consists of three parts: the left section 1, the right section 2, and the connecting arm 3. The right side segment 2 and the left side segment 1 are arranged parallel to each other, respectively comprising a right side segment proximal end 21, a right side segment distal end 22, a left side segment proximal end 11, and a left side segment distal end 12. The connecting arm 3 It is located between the proximal end 21 of the right section and the proximal end 11 of the left section. The three can be manufactured separately and then fastened, or they can be prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com