Process for production of articles made of gamma-prime precipitation-strengthened nickel-base superalloy by selective laser melting (SLM)

A nickel-based superalloy, precipitation strengthening technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of reduced productivity, low thermal conductivity of powder bed, expensive heating equipment process room, etc., to reduce time , good bulk density, the effect of reducing the shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

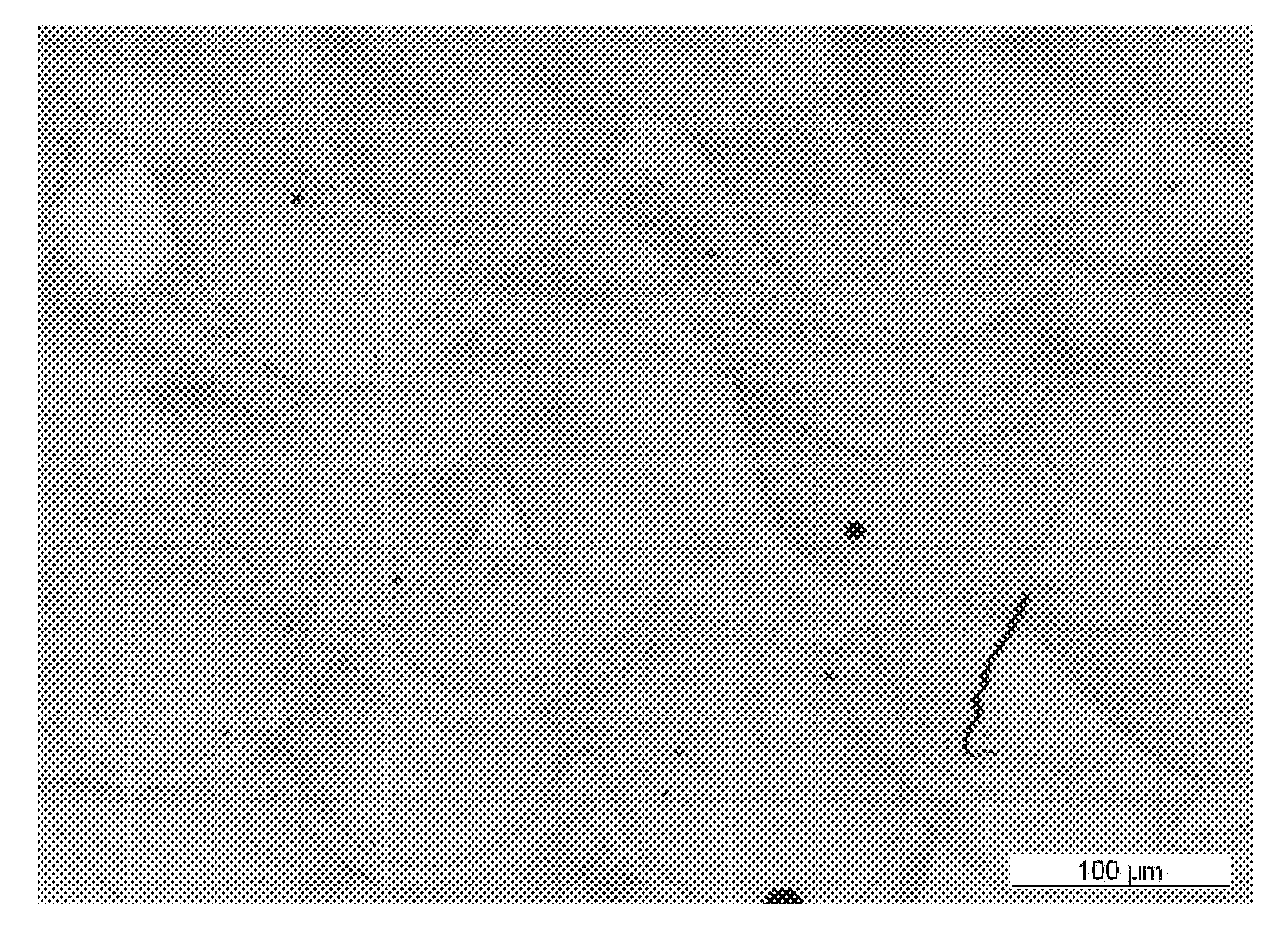

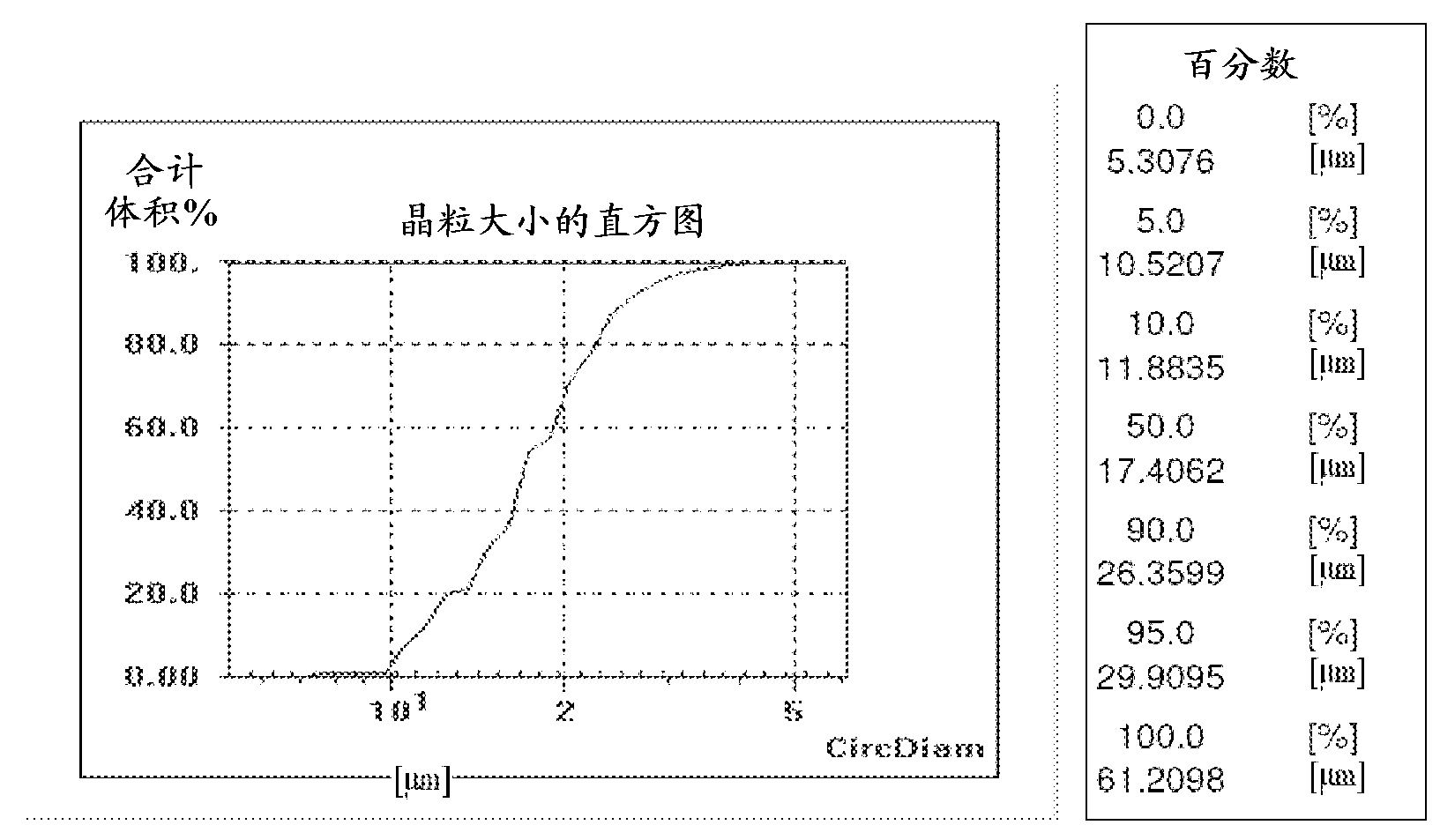

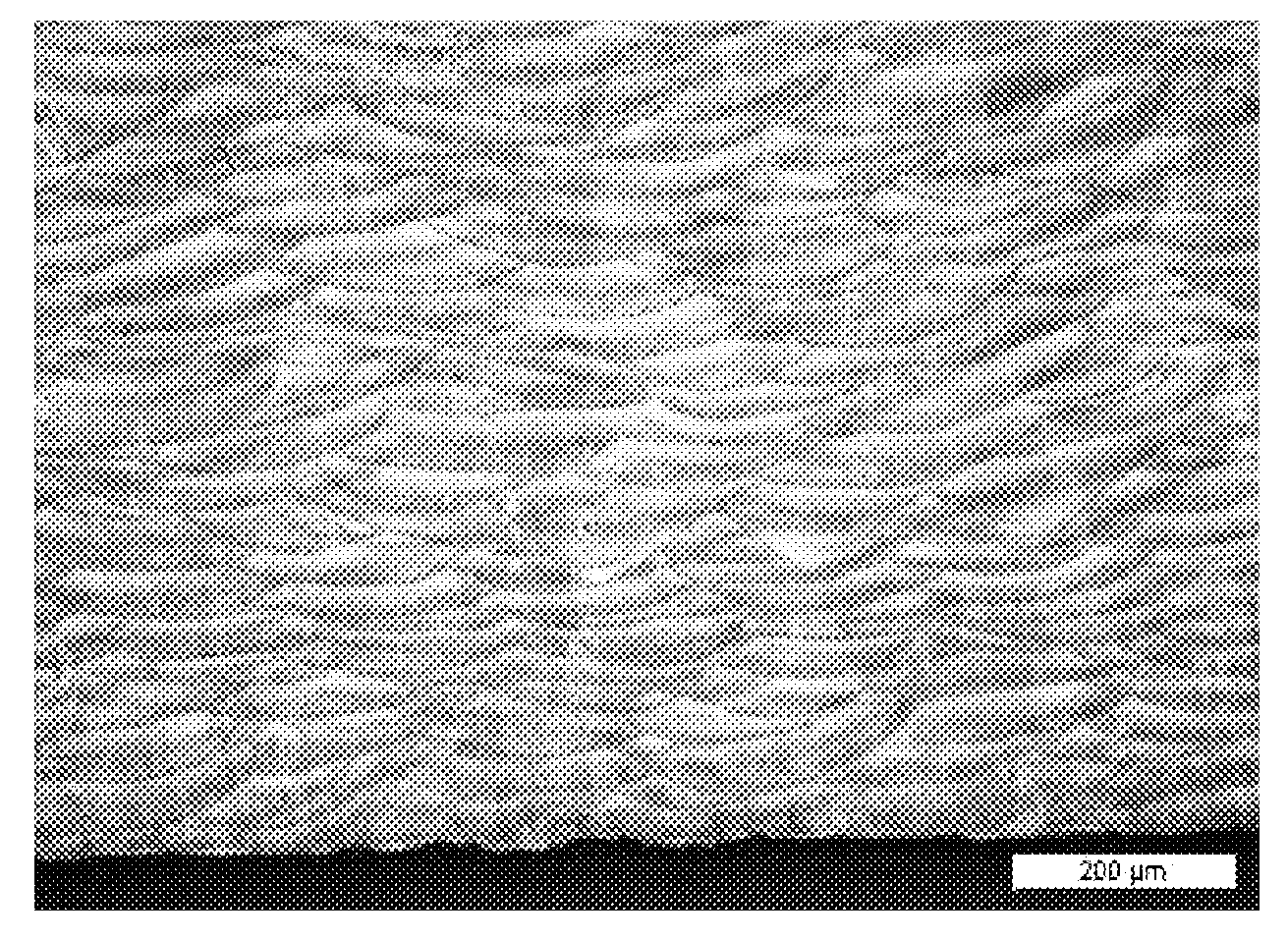

[0045] To overcome the limitations described above, the SLM process parameters are tuned with respect to the unique material behavior of γ' precipitation-strengthened superalloys, allowing the fabrication of crack-free and dense three-dimensional objects by selective laser melting without heating the powder bed or the part to be built . Furthermore, the use of specific process equipment was found to further improve the processability of these materials.

[0046] The present disclosure relates to a process for the production of three-dimensional objects made of γ' precipitation-strengthened nickel-based superalloys having a combined fraction of [2Al+Ti] exceeding 6 wt.-% using selective laser melting techniques (SLM) Equipment and specially adjusted process parameters. These superalloys by producing Ni 3 (Al,Ti) precipitates (known as gamma-prime (γ')) or Ni 3Nb (known as gamma-double-prime (γ'')) is strengthened by controlled heat treatment. These precipitates lead to bett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com