Punching shear punch capable of automatically changing tools

A technology for automatic tool changing and punching machine, applied in the field of punching and shearing punching machines, can solve the problem of low efficiency of manual tool replacement, save labor, shorten tool changing time, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

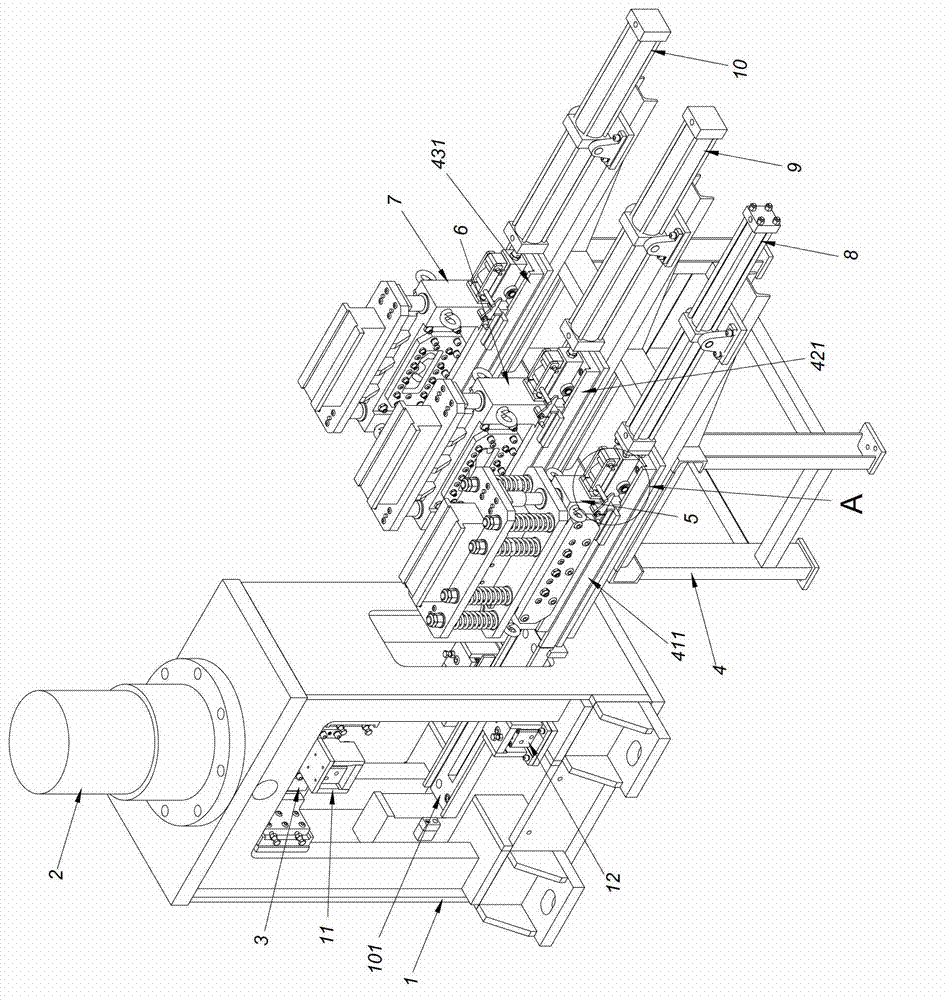

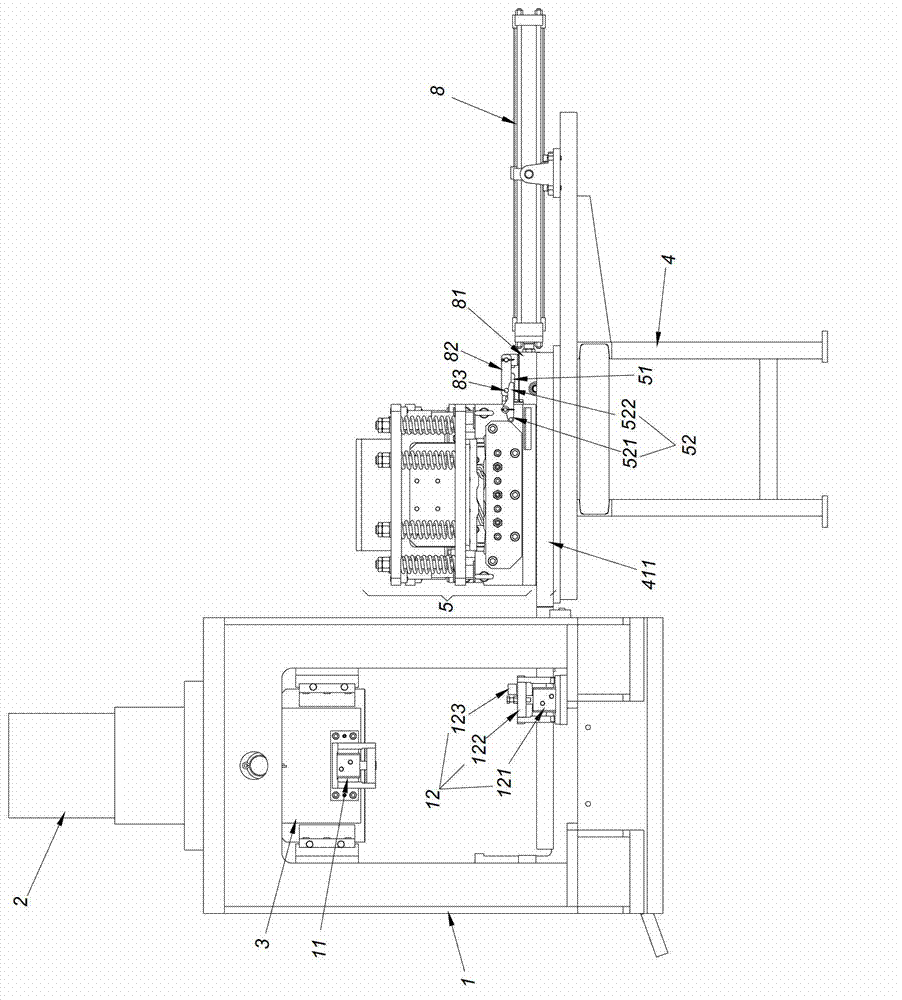

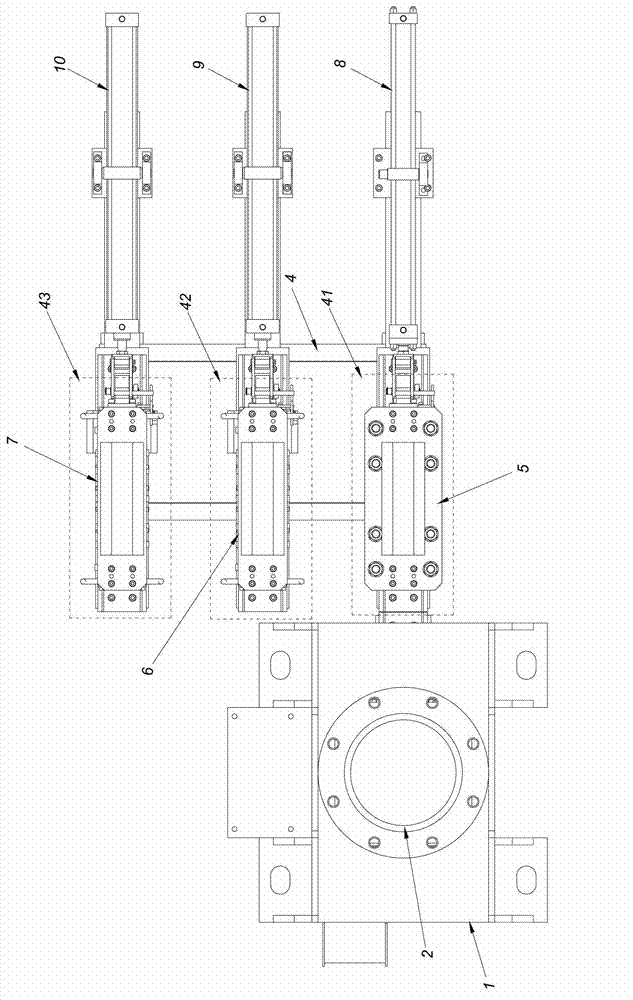

[0028] Such as figure 1 , figure 2 , image 3 As shown, the punching and shearing punching machine of this embodiment includes: a main frame 1, a main hydraulic cylinder 2 as a reciprocating power device, a moving knife connecting seat 3, a tool holder 4, a first tool combination 5, a second tool combination 6, a second tool combination Three knife combination 7, the first push-pull cylinder 8, the second push-pull cylinder 9 and the third push-pull cylinder 10. The first knife assembly 5, the second knife assembly 6, the third knife assembly 7 each comprise an upper knife and a lower knife.

[0029] A guide groove is provided between the movable knife connecting seat 3 and the main frame 1, so the movable knife connecting seat 3 can only move linearly along the vertical direction. The moving knife connecting seat 3 is driven by the main hydraulic cylinder 2. A movable knife clamping cylinder device 11 as a movable knife locking device is provided on the movable knife con...

Embodiment 2

[0038] Tool rest is arranged on the side of main frame among the embodiment 1. Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the tool rack is divided into a first tool rack 401' and a second tool rack 402', and the first tool rack 401' and the second tool rack 402' are arranged on the host Rack 1' on both sides. The first tool rack 401' is provided with a first placement position 41' and a second placement position 42', and the second tool rack 402' is provided with a third placement position 43', a fourth placement position 44' and a fifth placement position. Stands 45'. Such a layout can shorten the moving distance of the main frame along the conveying direction of the production line and save the length of the production line when there are many tool combinations available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com