Lead-screw-utilized twisting machine hand claw with fixed wiring harness position

A technology of robot hand and lead screw, which is applied in the direction of manipulators, circuit/collector parts, electrical components, etc., can solve problems such as wire harness rubbing, achieve precise assembly, improve production efficiency and product quality, and reduce labor requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

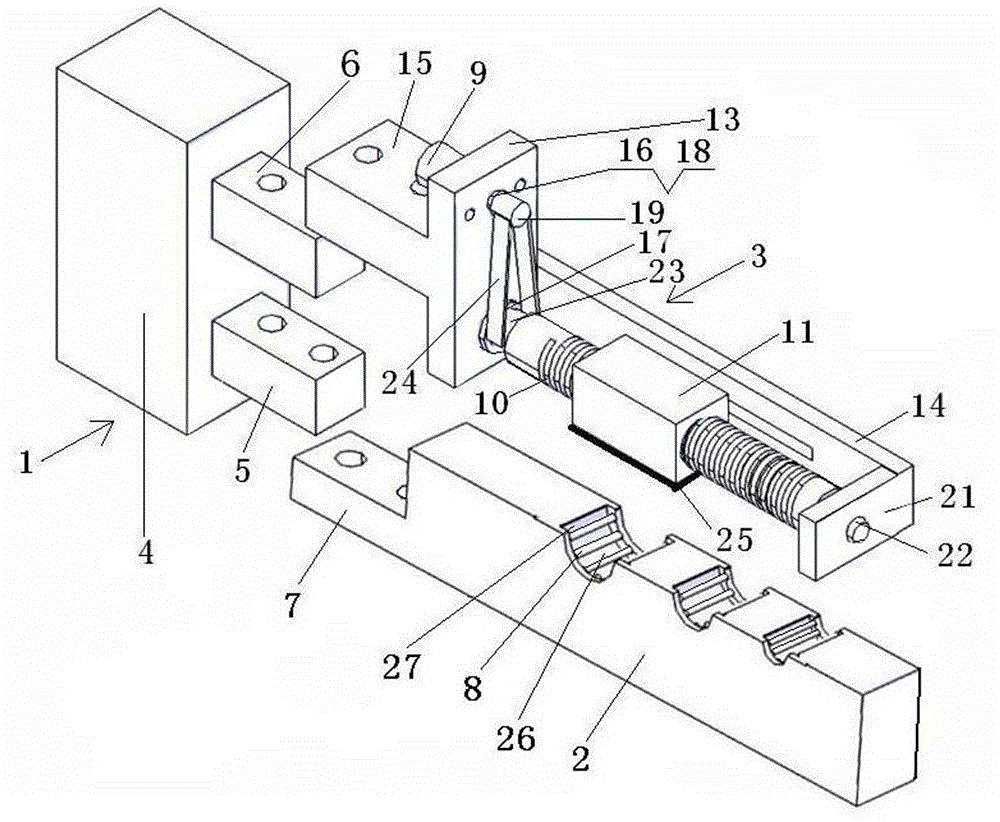

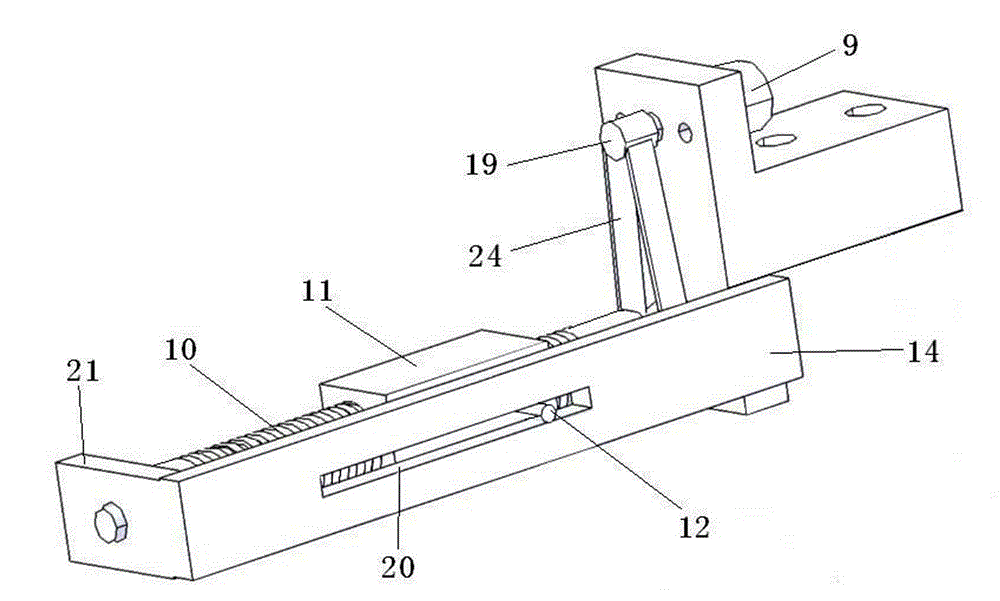

[0015] A wire harness position fixation utilizes a lead screw to rub the gripper of a robot, including a manipulator 1, a parallel motion finger 2 and a rubbing finger 3;

[0016] Manipulator comprises manipulator base 4, parallel motion finger base 5 and rubbing finger base 6, and the left end of rubbing finger base 6 is fixed on the right end face of manipulator base 4; Parallel motion finger base 5 is installed on the manipulator. The right end surface of the base 4 is located below the rubbing finger base 6, and is parallel to the rubbing finger base 6, and the parallel movement finger base 5 can move up and down in parallel with respect to the rubbing finger base 6 , is a known technology;

[0017] The left end of the parallel movement finger 2 is integrally provided with a movement finger connecting plate 7, the movement finger connection plate 7 is arranged below the parallel movement finger base 5, and is connected with the parallel movement finger base 5 by bolts, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap