Method for preventing knife drum from being abraded

A knife drum and flying knife technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problem of non-wear-resistant knife drums, and achieve the effects of prolonging service life, simple and practical structure, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

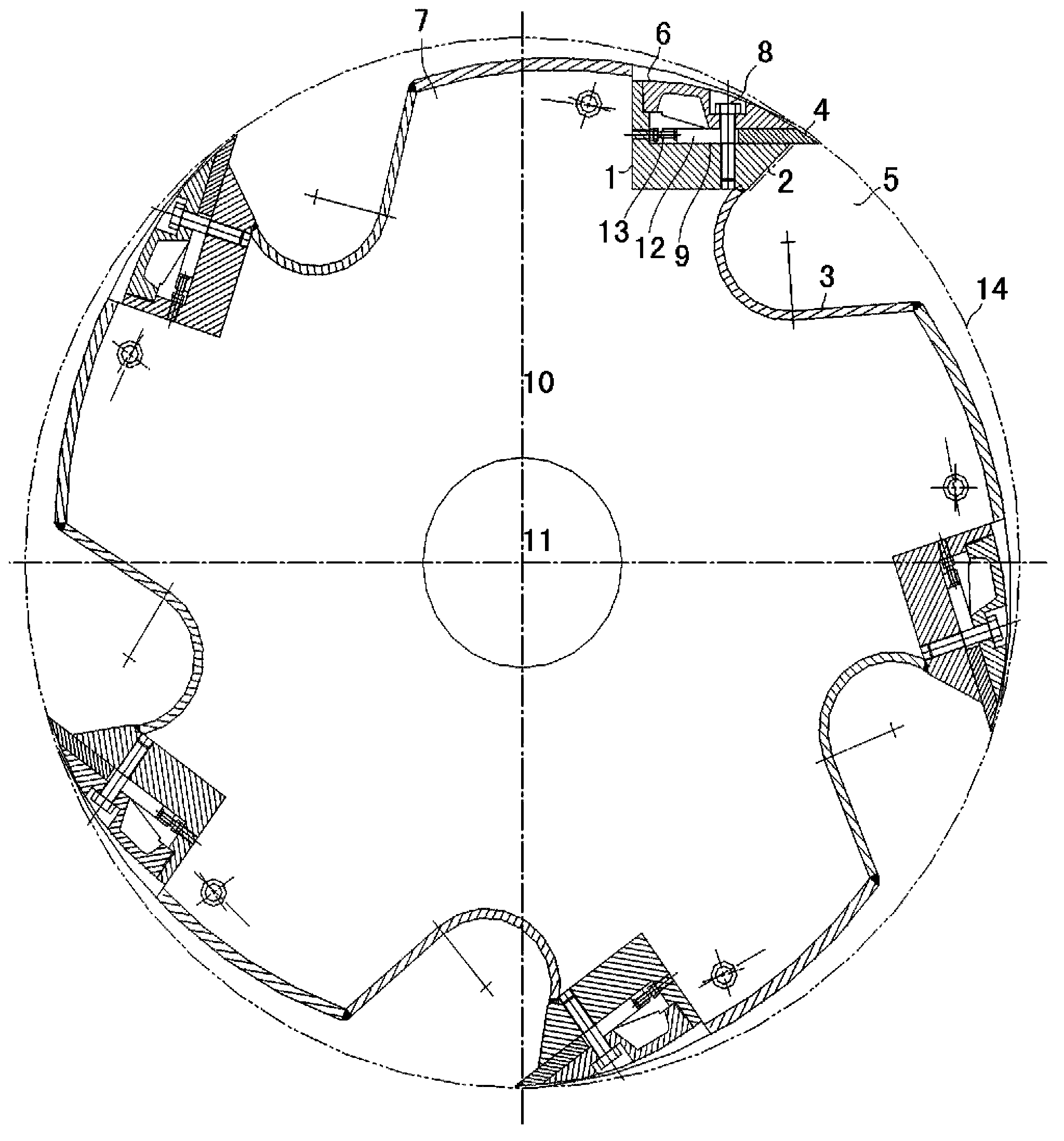

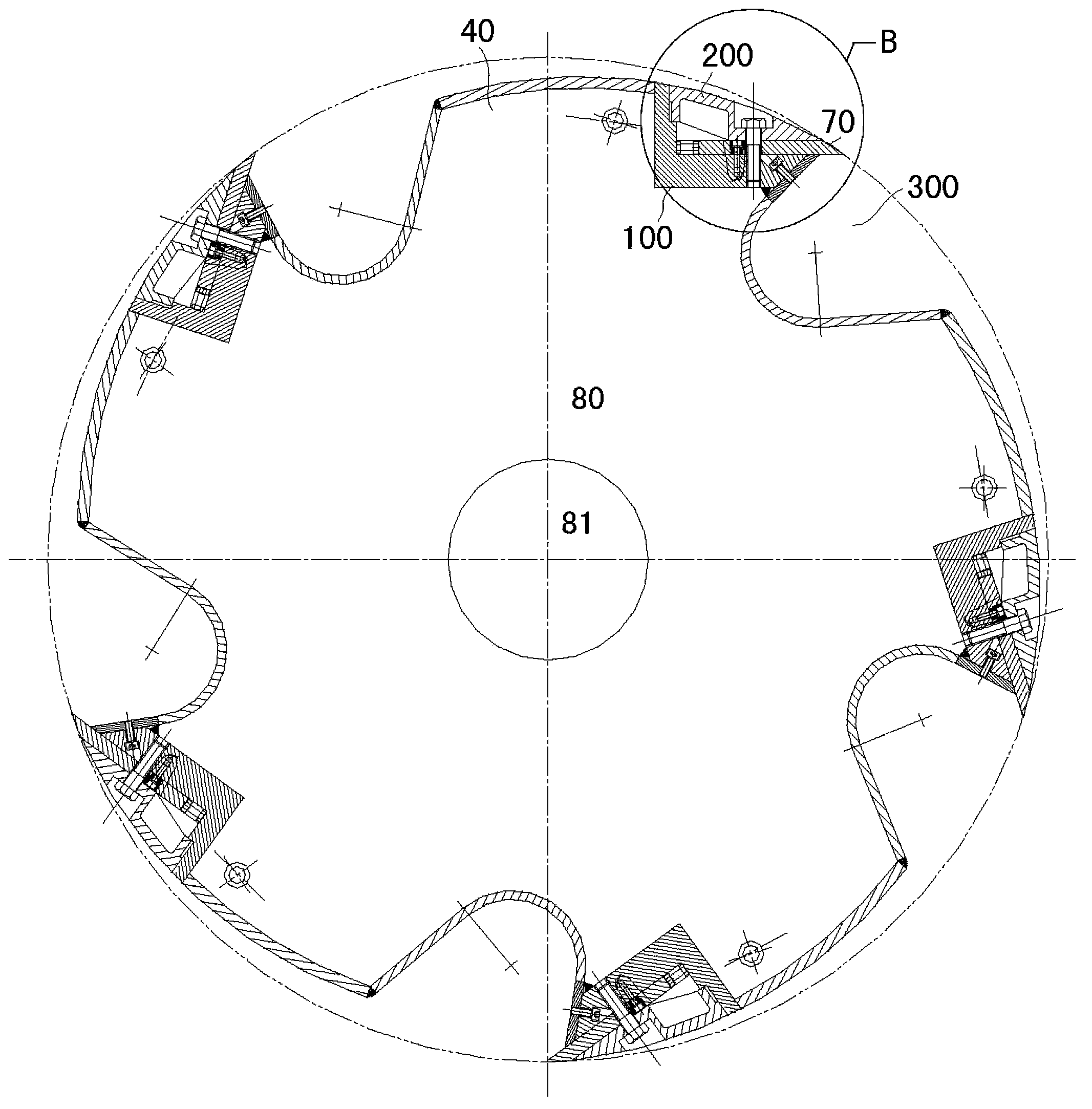

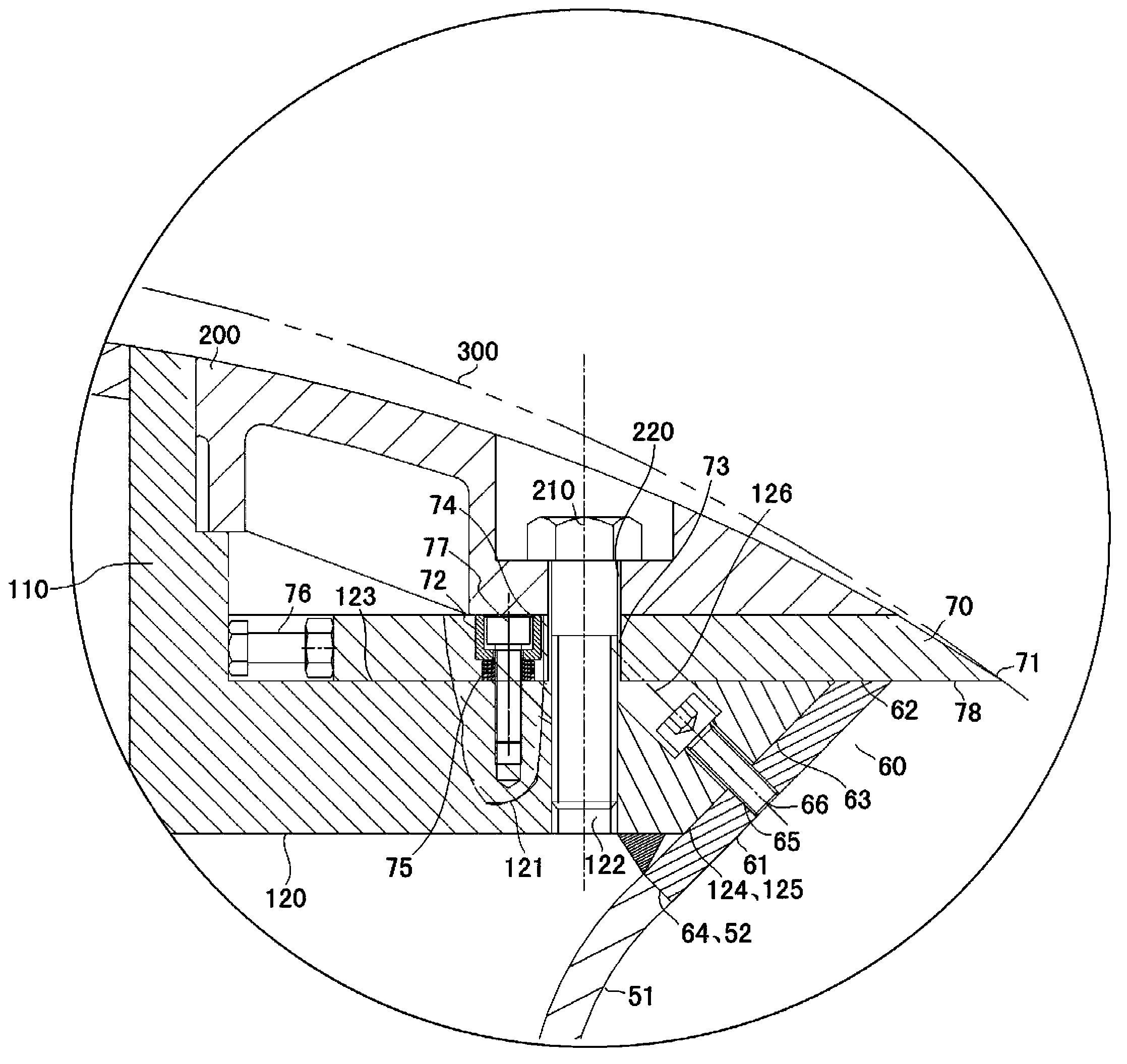

[0020] Such as Figure 2 to Figure 6 As shown, a wear-resistant knife drum used in a drum chipper provided in the figure includes four circumferentially evenly distributed lining plates 40 connected to each other, four circumferentially uniformly distributed flying knife support seats 100 and fixed on the lining plate 40 The end plates 80 at both ends have a shaft hole 81 in the center of the end plate 80 , wherein each flying knife support seat 100 is connected between two adjacent lining plates 40 . An arc-shaped cutting groove 51 is also provided on the lining plate 40 of the knife drum adjacent to the flying knife support seat 100 .

[0021] Each flying knife support seat 100 is L-shaped, which has a straight portion 110 and a transverse port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com