Method for fabricating customized insole

A manufacturing method and insole technology, which is applied in the field of insole manufacturing, can solve the problems of long time, high cost, non-compliance with human foot anatomy and sports biomechanical requirements, and achieve the effect of low cost and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

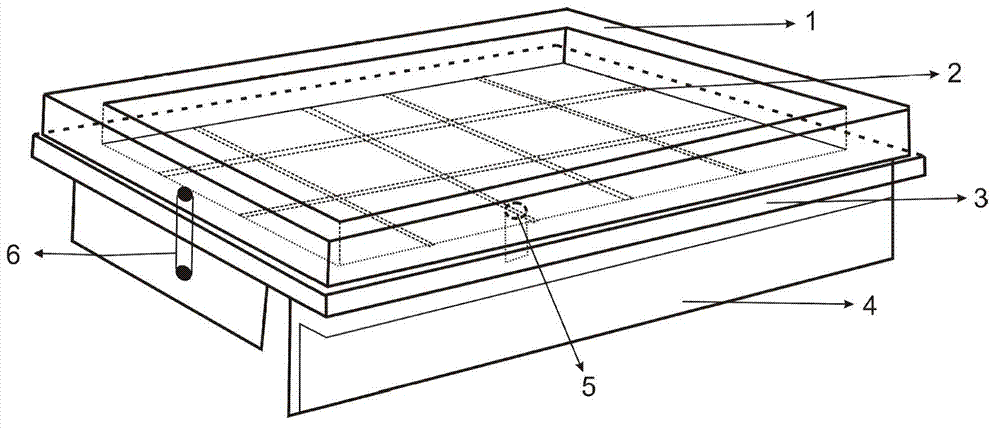

[0018] A kind of manufacturing equipment that the present invention is used is shown in the accompanying drawing, comprises the bottomless iron frame 1 tightly wrapped with soft rubber sheet material, and sheet material has properties such as high elasticity, high temperature resistance, airtight. Iron frame 1 is buckled on the hard backing plate 3 that is used to place the sole male mold, and backing plate 3 has certain thickness, is airtight, not easily deformed, and can withstand certain temperature. The bottom surface of the backing plate 3 is set on the iron bracket 4, and there are criss-cross grooves 2 on the part of the surface buckled by the iron frame 1. The diameter of the groove 2 is 1 cm, so that when the vacuum is pumped, other parts at the outlet The air in the part can be quickly sucked away through the small groove to ensure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com