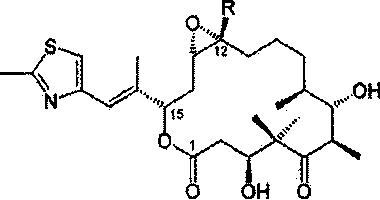

A method for inducing the expression of S. cellulosus to prepare epothilone

A technology of Cystobacter cellulis and inducing fibers, which is applied in the field of microbial fermentation of anti-tumor drugs, can solve problems such as low expression efficiency of epothilone, and achieve the effects of shortening fermentation culture time, improving fermentation efficiency, and simple analysis and elution method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] S1. Preparation of fermented strains: add the freeze-dried strains of S. cellulosus strain ATCC25532 into a test tube containing 3 mL of normal saline, shake evenly, and add 1 mL of the solution to a petri dish containing solid medium for coating uniform. Solid medium formula (all components are percentages by weight): 2% paper pulp, 2% potato starch, 1% peptone, 2% corn steep liquor, 0.2% dipotassium hydrogen phosphate, 2% agar powder, pH7.0, cultured on the basis of After sterilizing at 121°C for 20 minutes, add 20 mg of kanamycin B per liter of medium on the ultra-clean workbench, mix well, and pour it into a petri dish. Placed in a 28°C incubator for 48 hours. Scrape and inoculate evenly growing orange colony moss into a 500mL Erlenmeyer flask filled with 100mL of liquid medium, and place it in a constant temperature air bath shaker with a temperature of 28°C and a rotation speed of 220rpm for 72 hours. When the biomass reaches 10 9 CFU / mL is used as the fermenta...

Embodiment 2

[0063] S1. Preparation of fermented strains: add the freeze-dried strains of S. cellulosus strain ATCC25532 into a test tube containing 3 mL of normal saline, shake evenly, and add 1 mL of the solution to a petri dish containing solid medium for coating uniform. Solid medium formula (each component is weight percent): 1% paper pulp, 1% potato starch, 1% peptone, 1% corn steep liquor, 0.1% dipotassium hydrogen phosphate, 1.5% agar powder, pH7.0, cultured based on After sterilizing at 121°C for 20 minutes, add 15 mg of kanamycin B per liter of culture medium on the ultra-clean workbench, mix well, and pour it into a petri dish. Placed in a 25°C incubator for 40 hours. Scraped and inoculated the evenly growing and orange colony moss into a 500mL Erlenmeyer flask filled with 100mL of liquid medium, and placed it in a constant temperature air bath shaker with a temperature of 25°C and a rotation speed of 240rpm for 60 hours. When the biomass reached 10 9 CFU / mL is used as the fe...

Embodiment 3

[0070] S1. Preparation of fermented strains: add the freeze-dried strains of S. cellulosus strain ATCC25532 into a test tube containing 3 mL of normal saline, shake evenly, and add 1 mL of the solution to a petri dish containing solid medium for coating uniform. Solid medium formula (each component is weight percent): 5% paper pulp, 2% potato starch, 5% peptone, 2% corn steep liquor, 0.2% dipotassium hydrogen phosphate, 2% agar powder, pH7.0, cultured on the basis of After sterilizing at 121°C for 20 minutes, add 30 mg of kanamycin B per liter of culture medium on the ultra-clean workbench, mix well, and pour it into a petri dish. Placed in a 30°C incubator for 50 hours. Scraped and inoculated the evenly growing and orange colony moss into a 500mL Erlenmeyer flask filled with 100mL liquid medium, and placed it in a constant temperature air bath shaker with a temperature of 28°C and a rotation speed of 260rpm for 80 hours. When the biomass reached 10 9 CFU / mL is used as the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap