Three-phase-equilibrium electroslag refining furnace

A technology of electroslag remelting furnace and three-phase balance, which is applied in the field of three-phase balanced electroslag remelting furnace, can solve the problems of three-phase imbalance, achieve the effect of improving power factor, improving utilization rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings and embodiments of the description, the present invention will be further described.

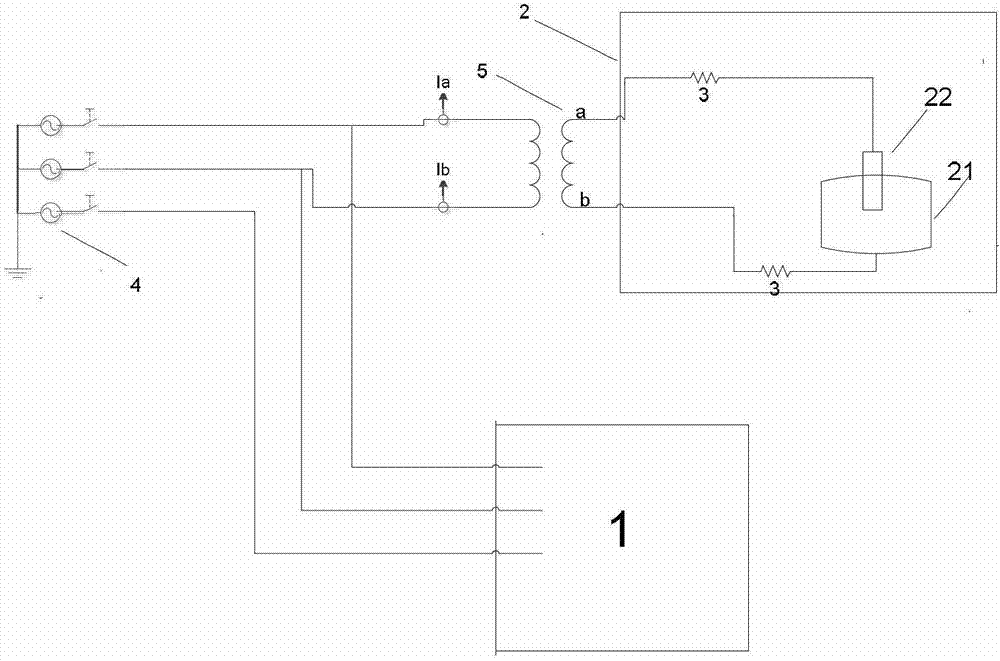

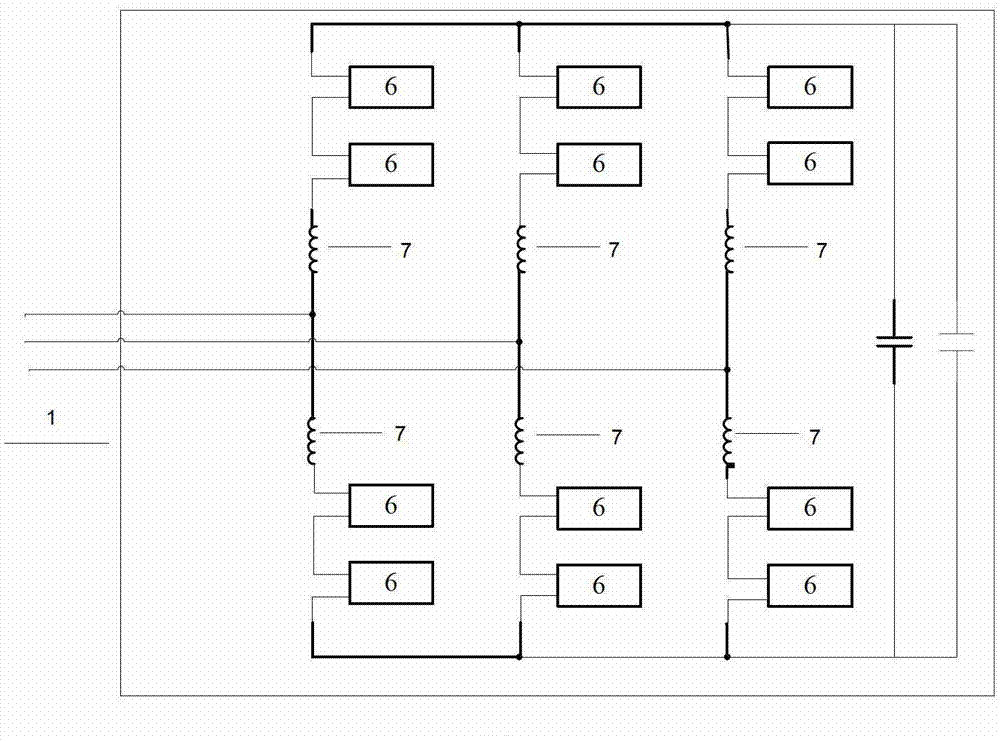

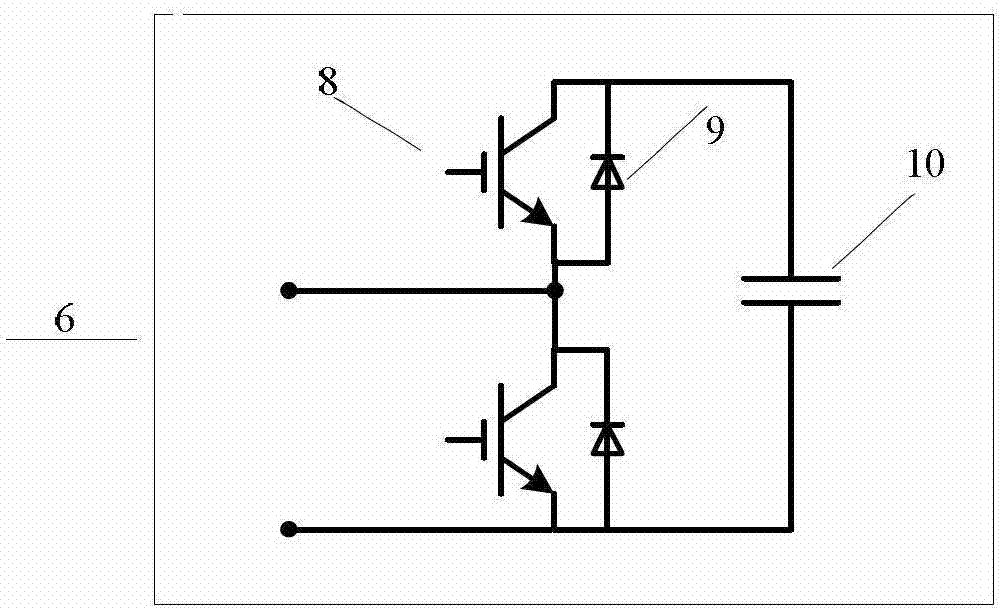

[0015] The three-phase balanced electroslag remelting furnace of the present invention includes a modular multi-level deviation correction device 1, a common electroslag furnace 2, a three-phase power supply 4 and a transformer 5, and the modular multi-level deviation correction device 1 passes through the three-phase The incoming line is connected to the three-phase power supply 4, and two phases of the three-phase power supply 4 are connected to the common electroslag furnace 2 through the transformer 5. Each bridge arm in the topology structure is connected to one phase of the three-phase power supply 4 through an L reactor 7 after two converter sub-modules 6 are connected in series. The converter sub-module structure in the modularized multi-level correction device 1 is a half-bridge structure, which is composed of two fully-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com