A vertical electrode hot water boiler device

A hot water boiler and electrode technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high electrode production cost, harsh installation and construction environment, and difficult sealing of traction shafts, and achieves a three-phase solution. Imbalance problem, improve quality assurance ability, produce the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

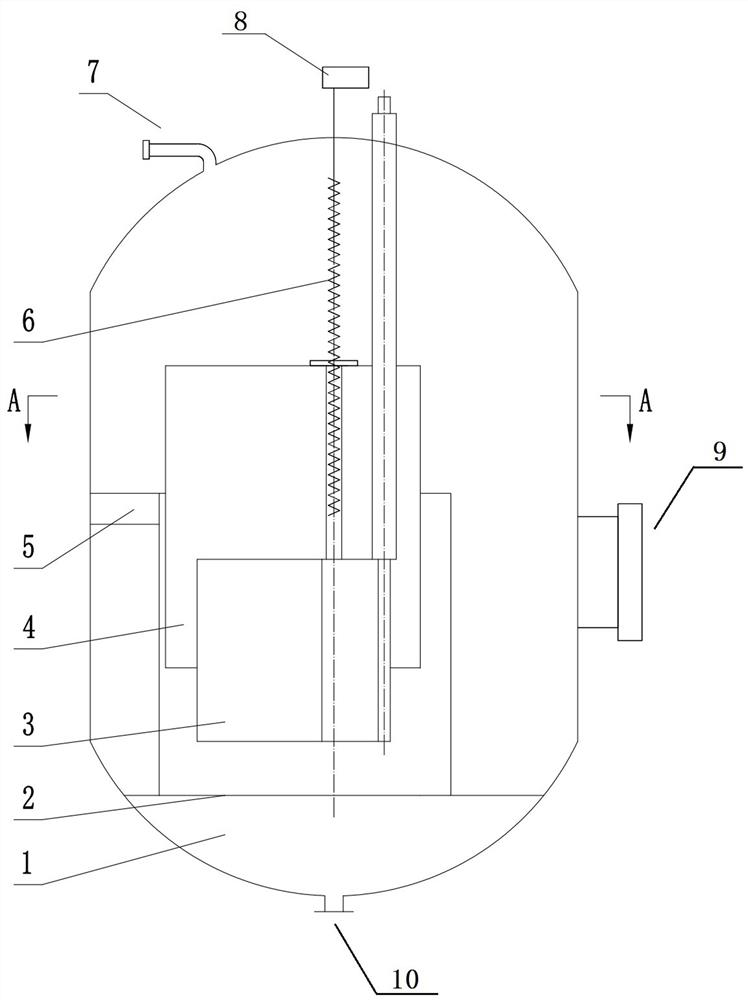

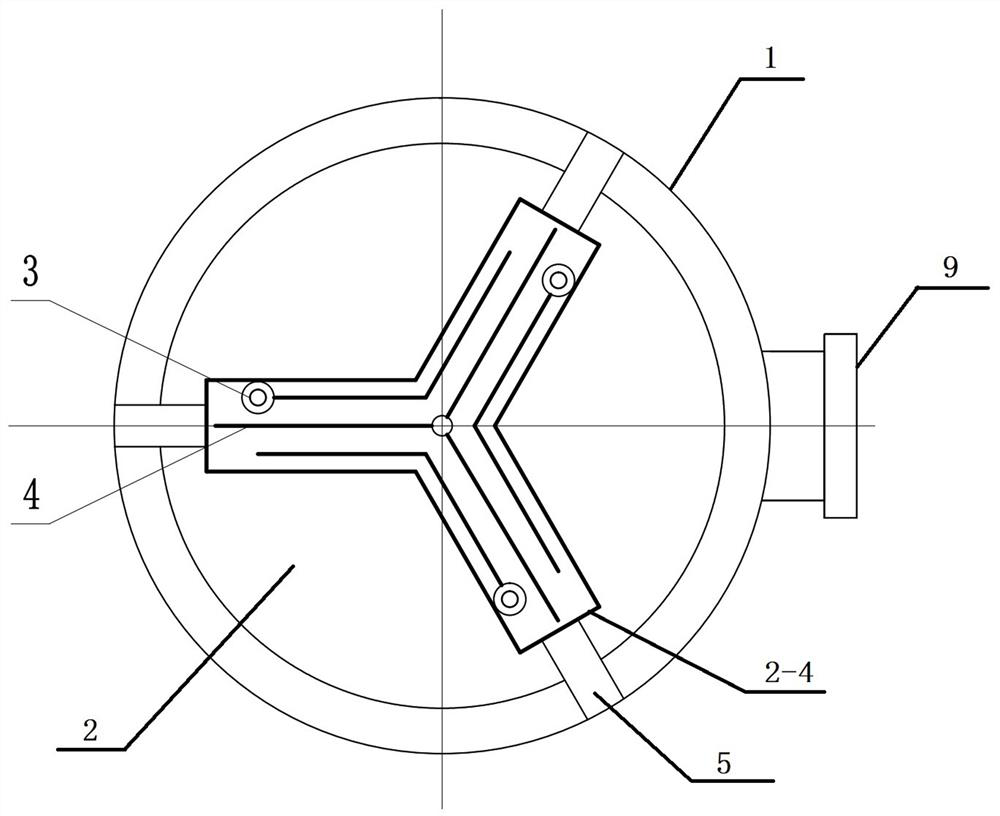

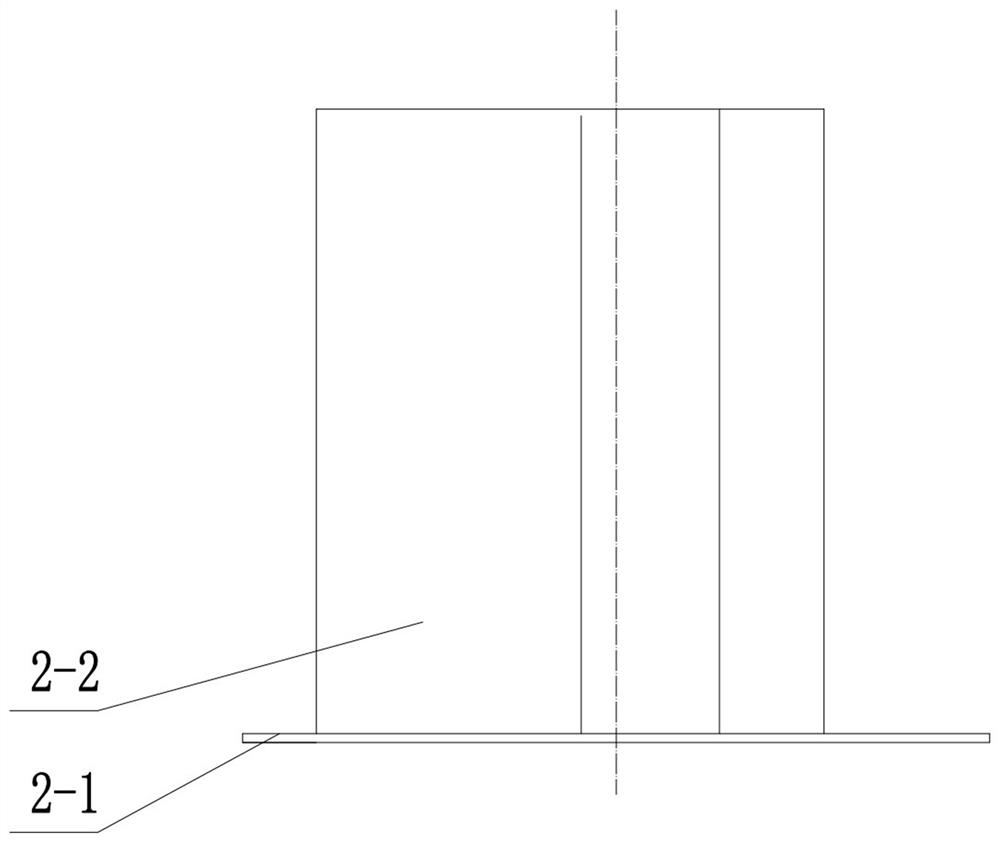

[0038] Embodiments of the present invention include figure 1 The shown large tank 1 is made of carbon steel material, the middle part is in the shape of a cylinder, the two ends are elliptical heads, and a manhole 9 is opened on one side of the cylinder, which is convenient for installation and maintenance. There are several holes on the head and the cylinder, including the water inlet hole 10 for connecting cold water, the water outlet hole 7 for receiving hot water, the access port of the electrode assembly 3, the access port of the lead screw 6 and the necessary Safety valve pipe, pressure gauge pipe, vent pipe, water discharge pipe and other nozzles not shown in the drawings, the bottom is fixed on the foundation with outriggers (the outriggers and foundation are not shown in the drawings).

[0039] The embodiment of the present invention also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com