Wheel disc false twisting spinning device

A roulette and false twisting technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of difficult industrial application, difficult control, high investment and operation costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

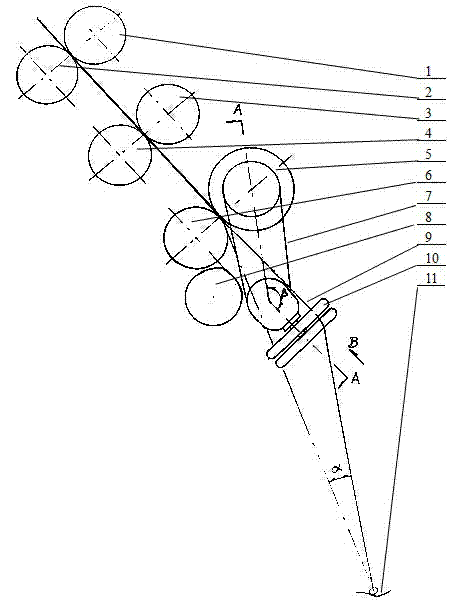

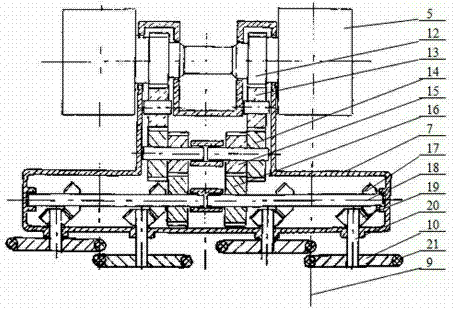

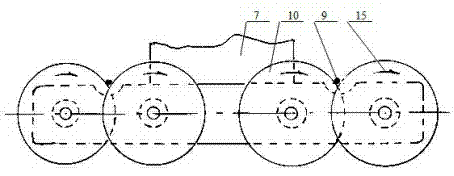

[0018] in figure 1 figure 2 image 3 The drafting part of the ring spinning frame is composed of top rear roller 1, bottom rear roller 2, top middle roller 3, bottom middle roller 4, top top roller 5, bottom front roller 6 and suction tube 8, etc. The device for twisting and false-twisting spinning is arranged between the front roller jaws composed of the front top roller 5 and the front bottom roller 6 and the yarn guide 11 at a position close to the front top roller 5. 10 and its transmission mechanism and the front top roller 5 are combined into a false twist component. The front top roller 5 is provided with a driving gear 12, and the driven gear 16 fixed on the auxiliary shaft 18 is driven through the intermediate gear 13, the double gears 14 and 15; the auxiliary shaft 18 is also fixed with two driving bevel gears 17, two The two driving bevel gears 17 respectively drive the corresponding two driven bevel gears 19, and the two driven bevel gears 19 drive the twisting whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com