Tentering and setting machine baking oven

A stenter setting machine and oven technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of low utilization rate of hot air, achieve the effect of improving utilization rate and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

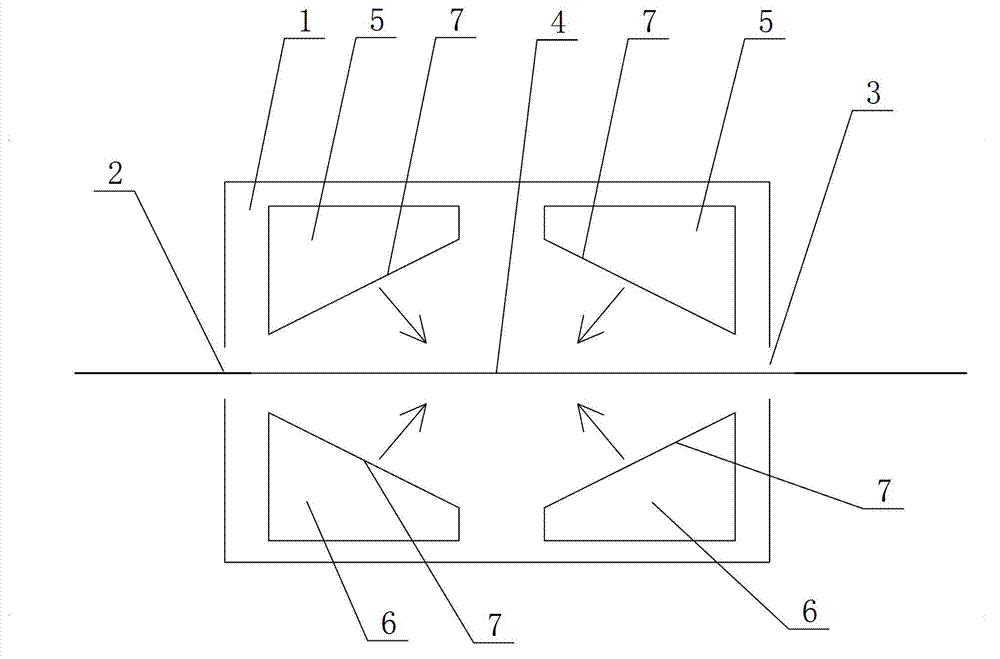

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0011] see figure 1 as shown, figure 1 It is a structural schematic diagram of the oven for the stenter setting machine provided in Embodiment 1 of the present invention.

[0012] In this embodiment, an oven for a stenter setting machine comprises an oven box 1, two ends of the oven box 1 are provided with a cloth inlet 2 and a cloth outlet 3, and a conveyor belt 4 passes through the cloth inlet of the oven box 1. The mouth 2 and the cloth outlet 3 are set, and there are multiple groups of hot air passages correspondingly arranged above and below the conveyor belt 4 in the oven body 1 (only two groups of hot air passages located at the outermost end are shown in the figure, in the In actual application, there are multiple sets of hot air ducts arranged in the oven), and the two sets of hot air duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com