Headboxes for fiber web machines

A technology of fiber web machine and headbox, which is applied in the direction of paper machine, paper machine wet end, textile and paper making, etc. It can solve the problems affecting the investment cost of the machine and achieve the effect of eliminating demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

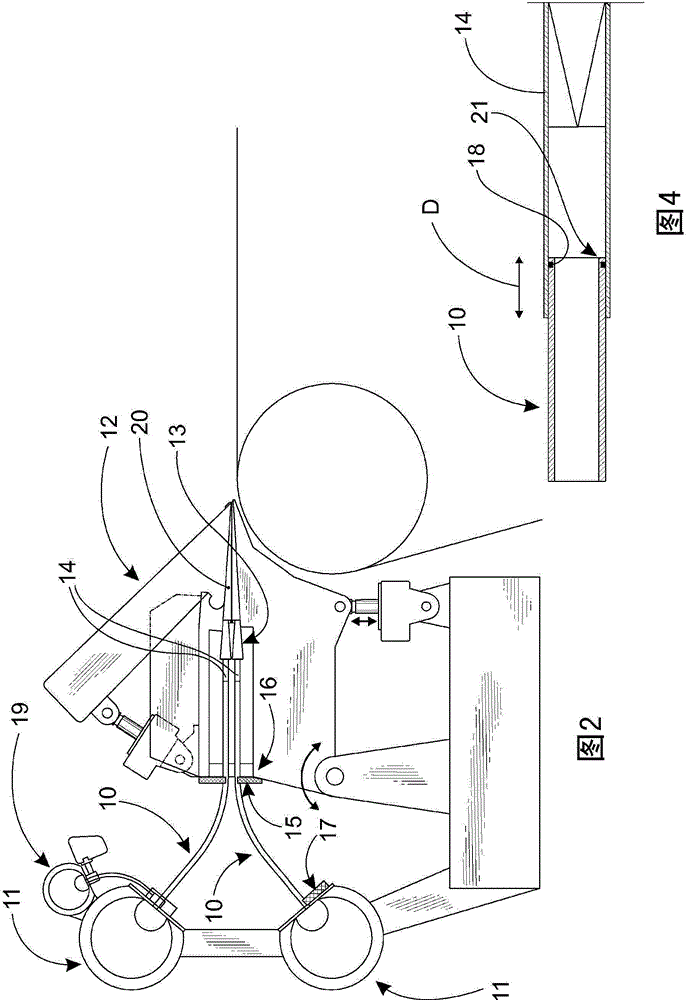

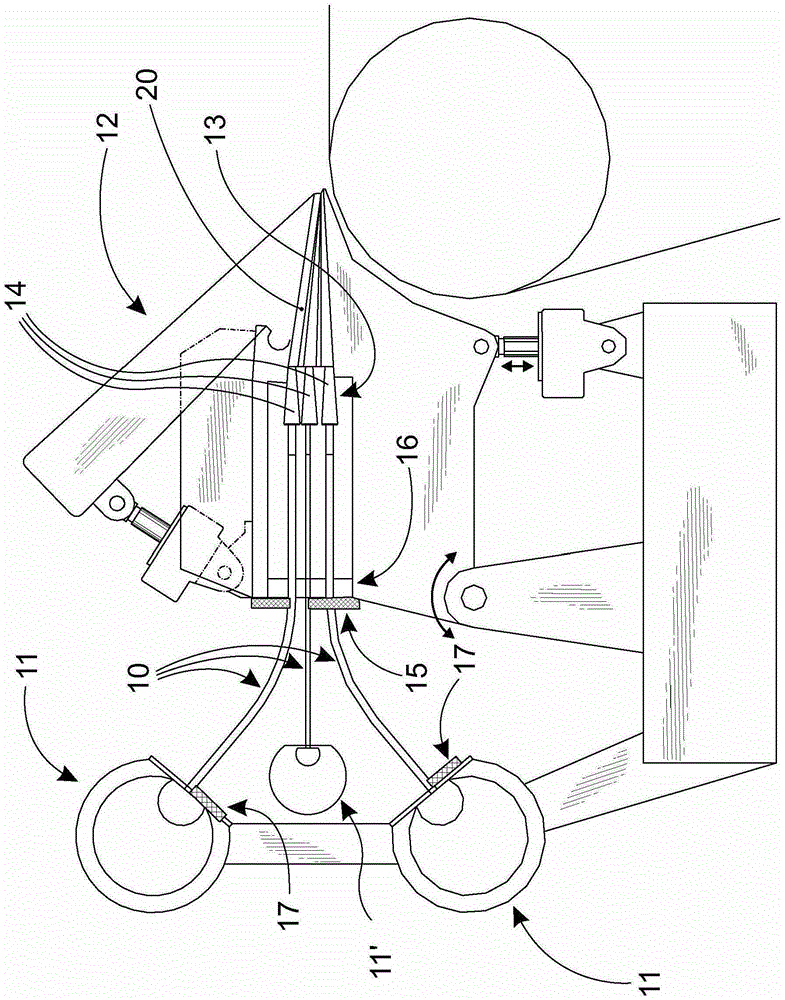

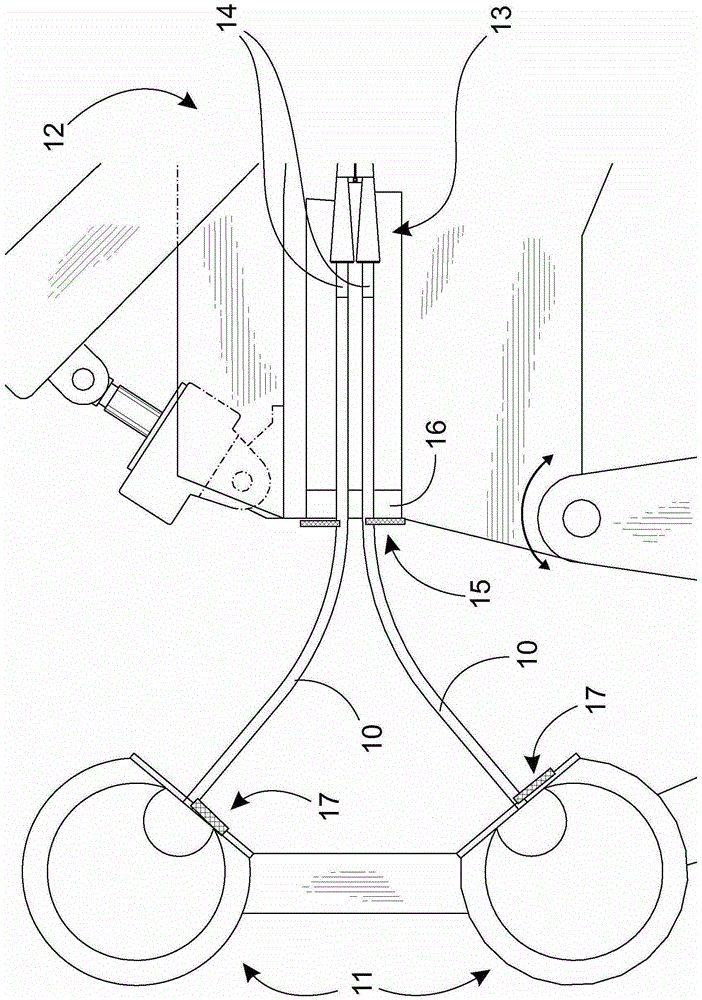

[0014] Figure 1 to Figure 3 is a side sectional view of an embodiment of a headbox 12 for a fiber web machine. The headbox 12 comprises, in a manner known per se, a turbulence generator 13 equipped with flow tubes 14 . For example, at least one manifold 11, 11' The manifold 11, 11' is usually a tubular manifold 11 for example for pulp suspension, but it could also be a manifold 11' for example for dilution water, or another type of pulp suspension delivery system such as a so-called Octopus manifold (octopusmanifold, not shown).

[0015] exist figure 1 , two pulp suspension manifolds 11 and one dilution water manifold 11' are connected to the headbox 12 through these intermediate pipes 10 to provide a water layer. exist figure 2 , an intermediate pipe 10 is used to connect the two manifolds 11 to the headbox 12. A manifold 19 of dilution water for the basis weight profile of the fiber web is located close to the second manifold 11 from which the dilution water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com