Steel girder rod piece assembling movable and telescopic high-strength bolt screwing platform

A technology of mobile telescopic and sliding platforms, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of occupying construction resources and time, cumbersome problems, etc., to improve screwing efficiency, reduce construction time, and have strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

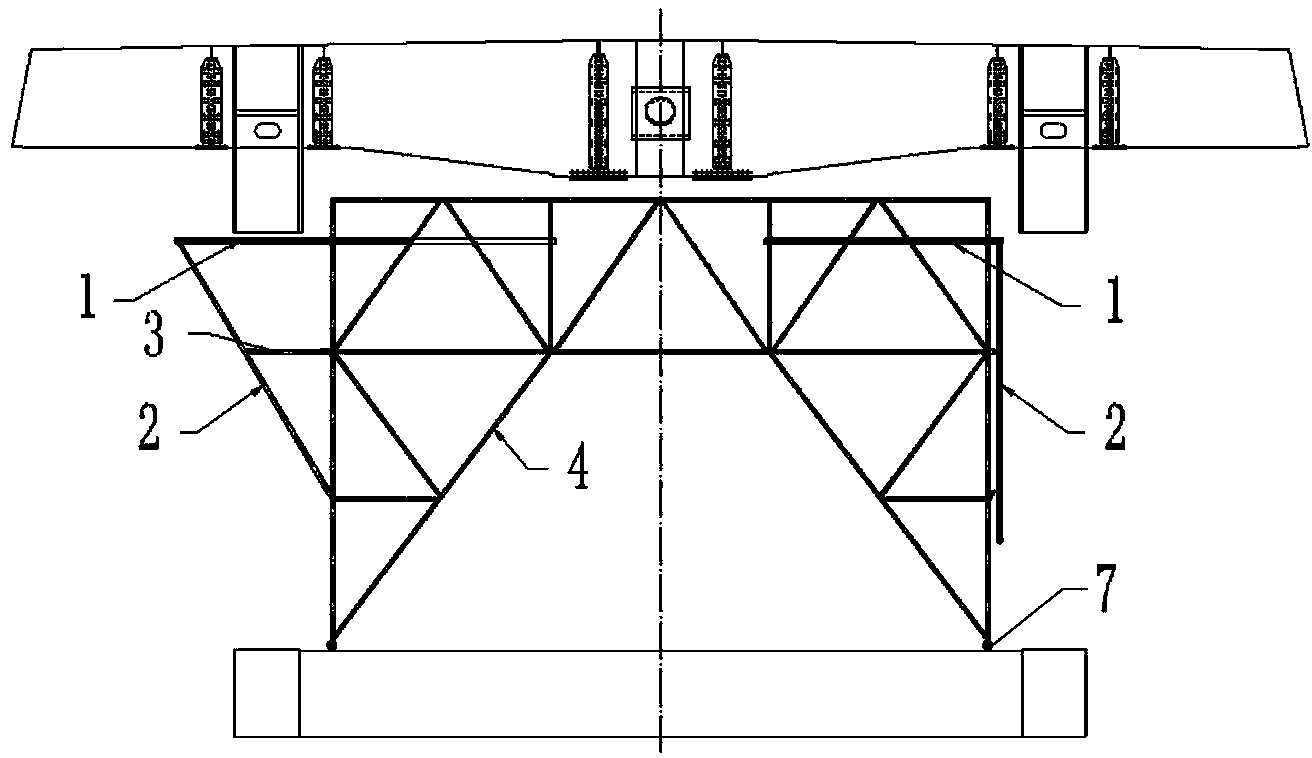

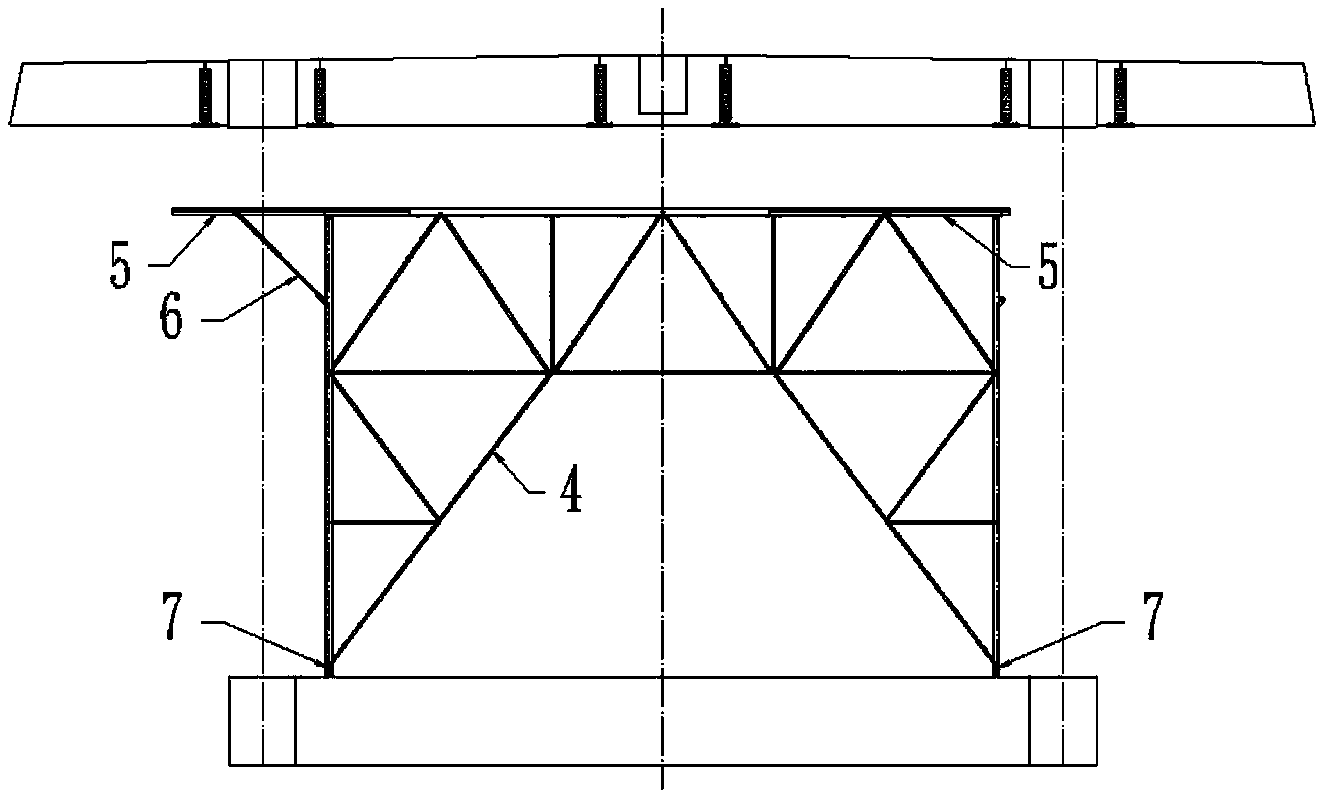

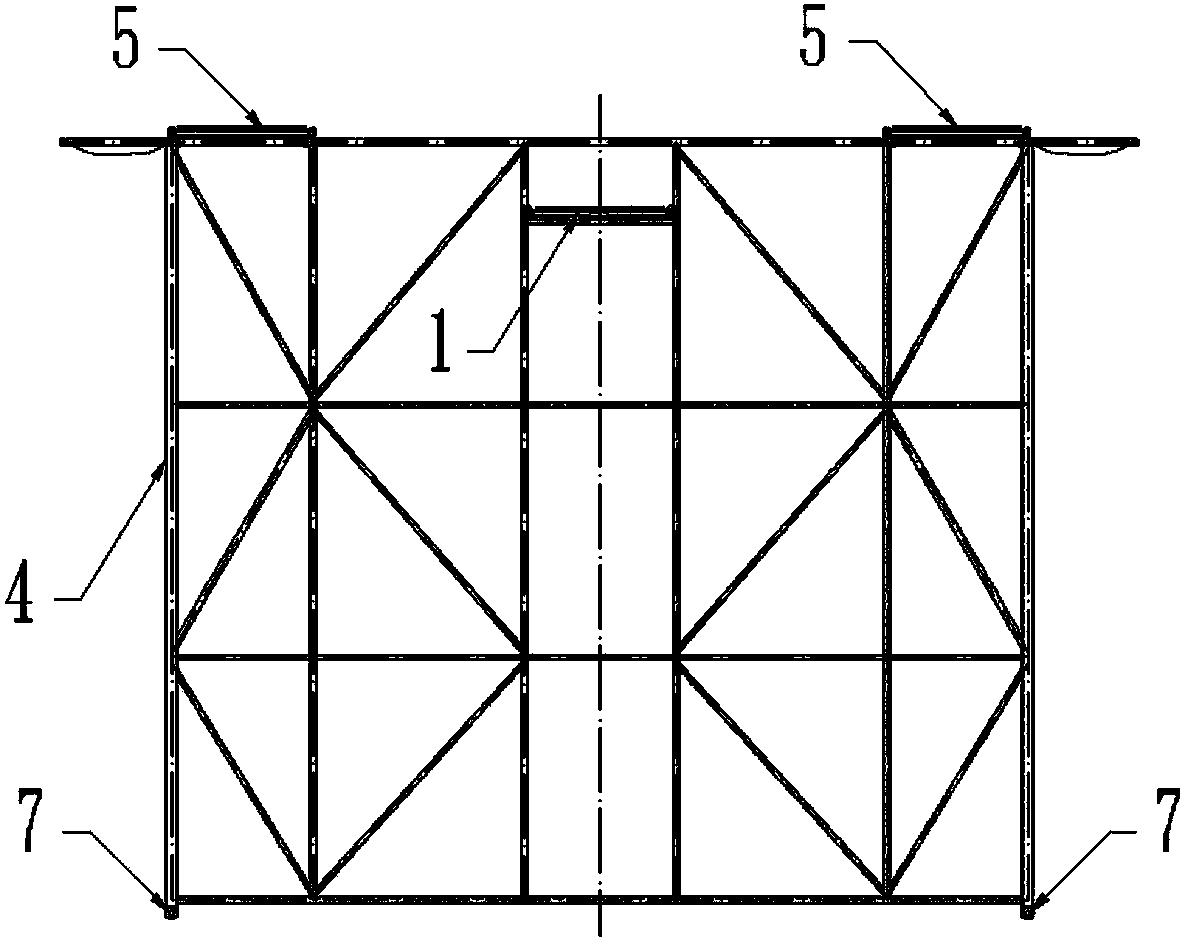

[0017] See attached Figure 1~4 , a movable telescopic high-bolt screwing platform assembled with steel beams and rods according to the present invention, comprising a steel pipe support 4, the bottom of the steel pipe support 4 is provided with walking wheels 7, and the upper part is provided with two telescopic sliding platforms perpendicular to each other. It includes a second sliding platform 5 arranged vertically on the top of the steel pipe support 4 , and a first sliding platform 1 arranged horizontally below the second sliding platform 5 . A channel steel slideway 8 is respectively arranged between the first sliding platform 1 and the second sliding platform 5 and the steel pipe support 4, and lubricating oil is smeared in the channel steel slideway 8, and the first sliding platform 1 and the second sliding platform The platforms 5 are installed on the channel steel slideways 8 through a sliding platform bearing 9 respectively. The first platform brace 2 is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com