Spiral distributed multi-hole end face rotary sealing ring used on vehicle

A technology of rotating sealing ring and hole end face, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., which can solve the problems of overall failure of traditional devices and failure of rotating seal, so as to improve service performance and life, reduce friction and wear, Effect of reducing frictional torque and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

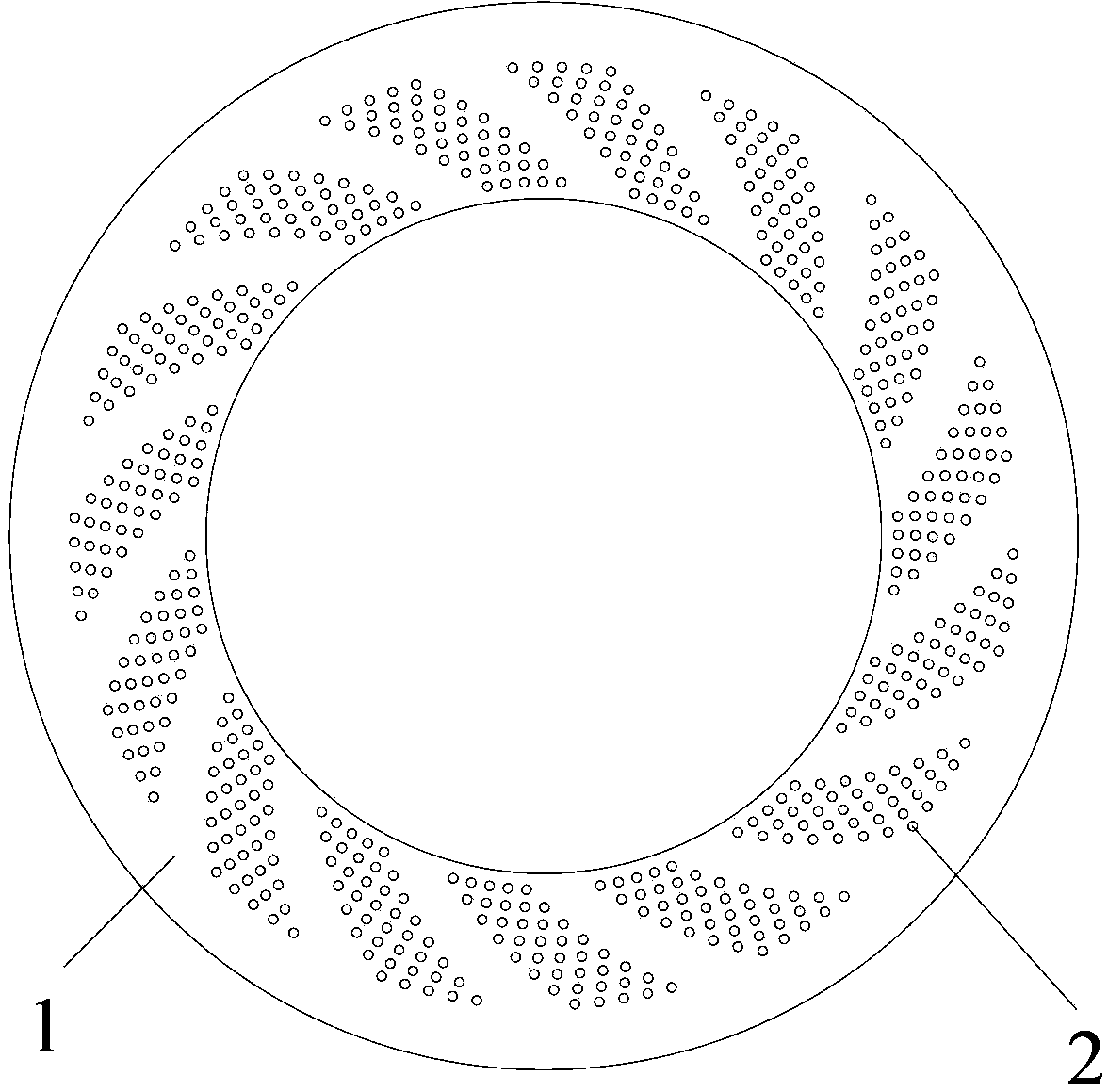

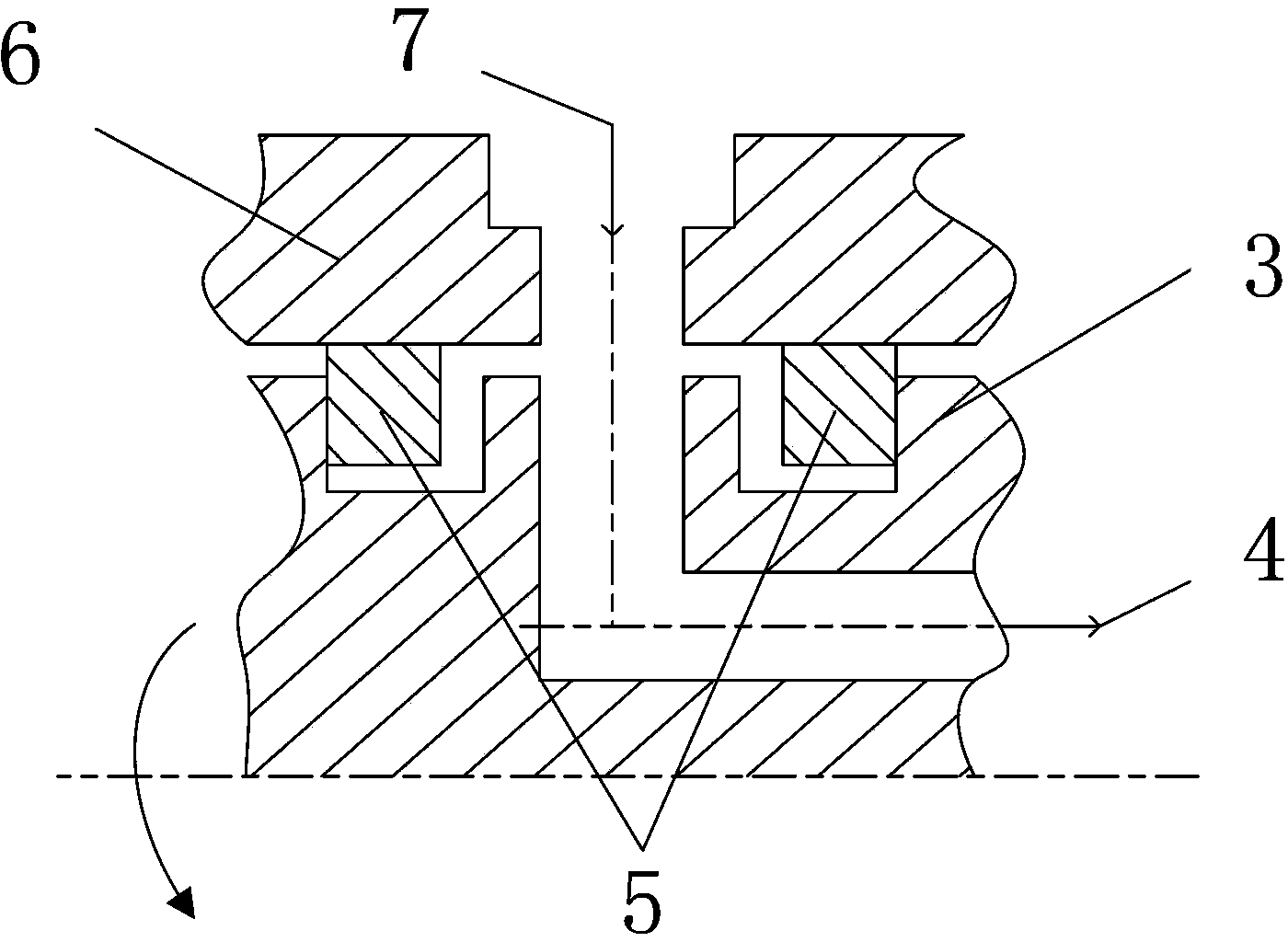

[0017] as attached figure 1 And attached figure 2 As shown, the present invention provides a rotary seal ring for vehicles with a helically distributed porous end face. The end face of the rotary seal ring 1 is evenly distributed along the circumferential direction with 15 helical regions, and each helical region is formed by the inner circle of the seal ring. Extending outward, micropores 2 are evenly distributed in each helical area, and the area formed between adjacent helical areas is a platform area.

[0018] Each microhole 2 is a circular hole with a radius of 0.2mm, the depth-to-diameter ratio of the microhole 2 is 0.008, and the overall area ratio of the microhole (the sum of the surface area of the microholes on the end face of the sealing ring to the area ratio of the end face of the sealing ring) is 0.2.

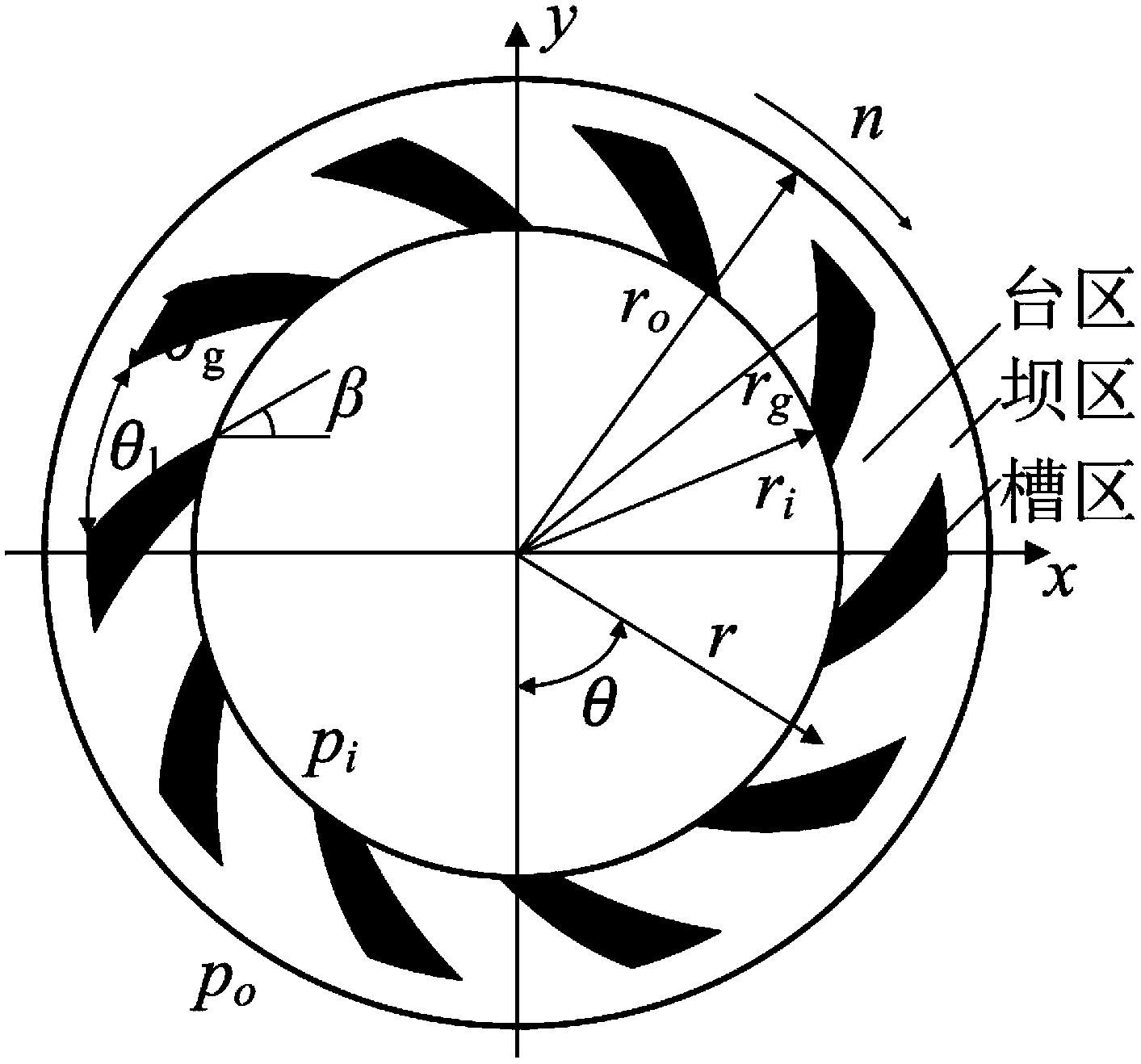

[0019] The helix angle θ of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com