Seal valve switch electric machine

A technology for switching motors and sealing valves, applied in shaft seals, valve details, valve devices, etc., can solve the problems of inaccurate control of valve medium flow, no self-locking ability of electric devices, large flow fluctuations, etc., and achieve simple structure , Reduce drive power, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

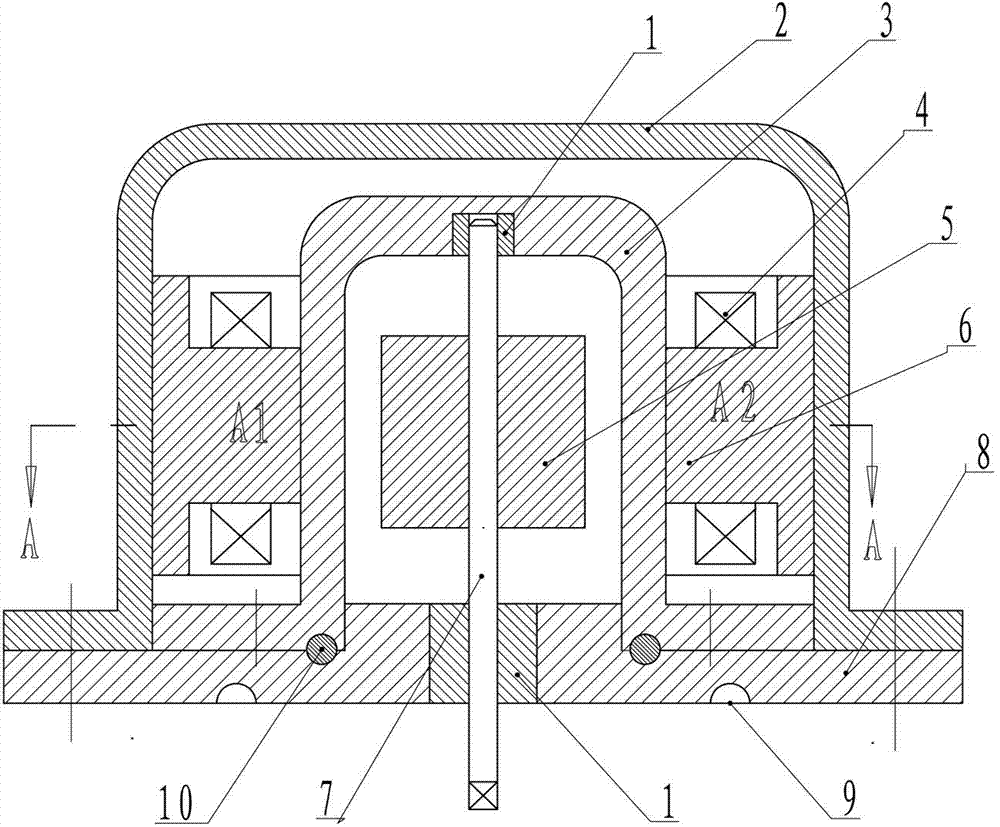

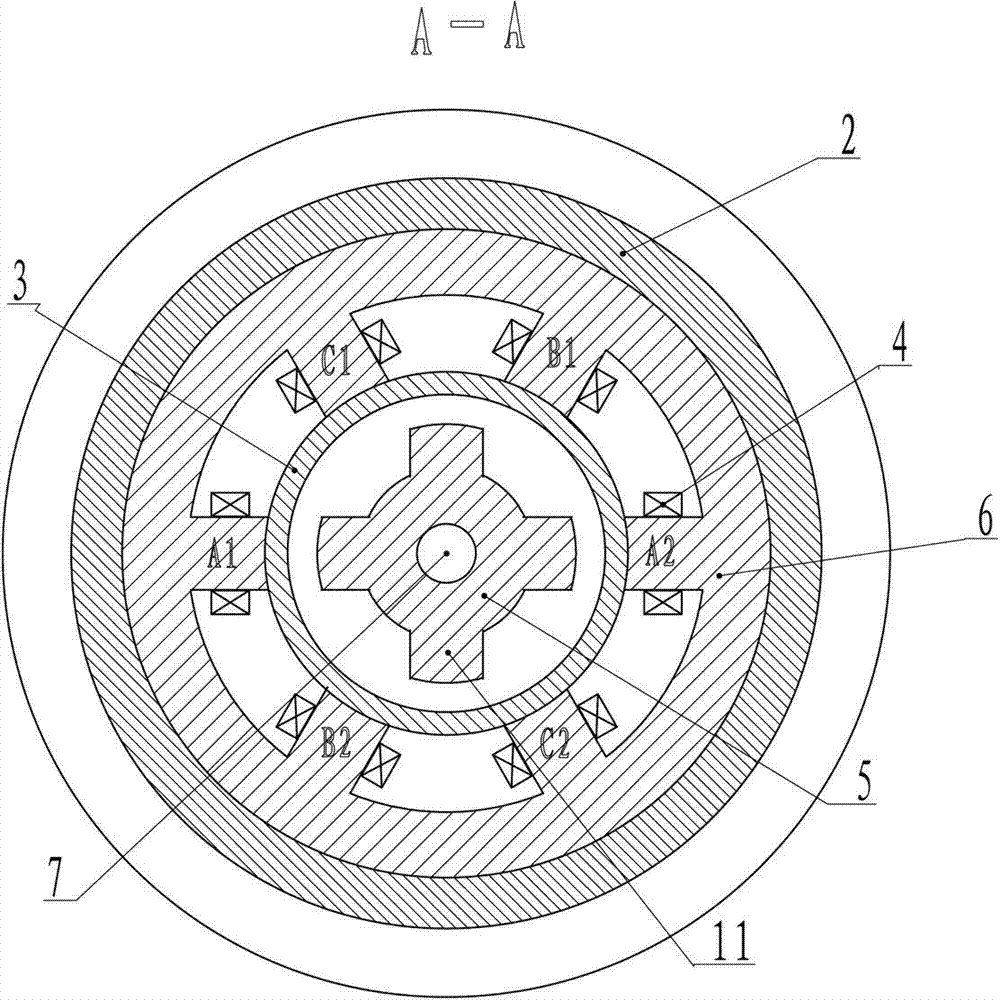

[0029] Example 1 (see figure 1 , 2 ):

[0030] Depend on figure 1 , 2 The illustrated embodiment 1 includes a housing 2, a stator, a rotor, a rotor shaft 7, a spacer 3 and a base 8; the spacer 3 is located between the rotor and the stator, and the spacer 3 is fixed on the base 8 with screws. A first sealing ring 10 is provided between the spacer 3 and the base 8; the upper end of the rotor shaft 7 is installed on the top wall of the spacer 3, and the lower end of the rotor shaft 7 extends out of the base 8; the stator includes a stator iron Core 6 and stator coil 4, each stator coil 4 is sleeved on its corresponding stator pole; An annular groove 9 for placing a sealing rubber ring is provided on the bottom surface of the base 8; The housing 2 is fixed on the base by bolts 8 on.

[0031] The rotor is a first soft magnetic rotor 5 , and soft magnetic rotor poles 11 corresponding to the stator poles are evenly distributed on the side wall of the first soft magnetic rotor...

Embodiment 2

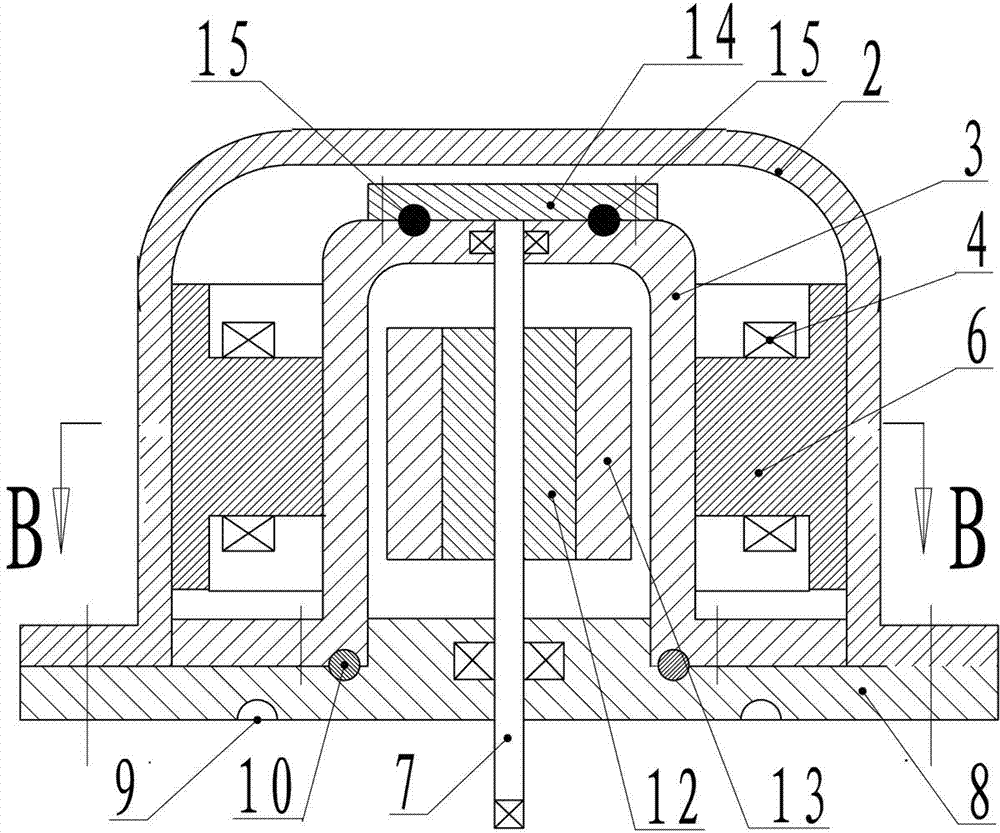

[0037] Example 2 (see Figure 3-4 ):

[0038] Depend on image 3 , 4 Embodiment 2 can be known, and embodiment 1 is different in that: described rotor is made of second soft magnetic body rotor magnetic pole 12 and the permanent magnet rotor magnetic pole 13 that is evenly distributed on the second soft magnetic body rotor magnetic pole 12 sidewall, and described permanent magnet rotor The number of magnetic poles 13 is adapted to the number of stator magnetic poles.

[0039] The number of the stator poles is 6, and the number of the permanent magnet rotor poles 13 is 4.

[0040] The two ends of the rotor shaft 7 are respectively mounted on the top wall and the base 8 of the spacer 3 through bearings, and a gland 14 is fixed on the top surface of the spacer 3, and between the gland 14 and the spacer 3 There is a second sealing rubber ring 15.

[0041] Embodiment 2 is used for the use status of the double valve plate sealing valve 16, see Figure 6 , Figure 6 A worm gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com