Sleeve-tooth-shaped floating sealing structure penetrating casing

A floating seal and tooth-shaped technology, applied in the direction of sealing surface connection, passing components, mechanical equipment, etc., can solve the problems of increasing the difficulty of assembly work, reducing the assembly of the casing, and colliding with pipelines, so as to improve maintainability and reduce installation. Stress, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

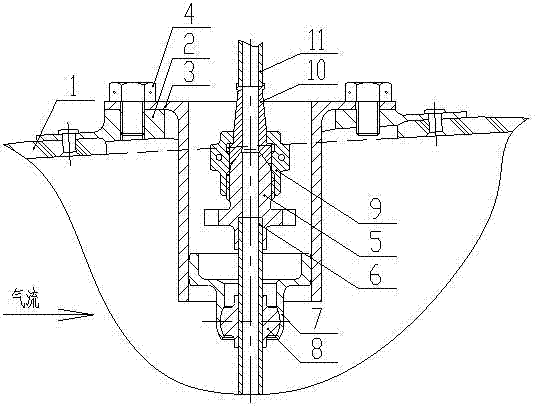

[0018] This embodiment provides a tooth-shaped floating seal structure for passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a lead-out pipe sleeve 3, bolts 4, an outer cone joint 5, Conduit 6, ball seat 7, ball head 8, extra nut 9, flat nozzle 10, conduit 11;

[0019] Among them: the outer cone joint 5 and the conduit 6 are welded together, which is the casing inner conduit assembly; the external nut 9, the flat nozzle 10, and the conduit 11 are welded together, which is the casing outer conduit assembly, and the casing mounting seat 2 is welded or riveted On the casing 1, the lead-out tube sleeve 3 is fixed on the casing mounting seat 2 through six bolts 4, and is closed through the ball head seat 7, so that it is assembled with the ball head 8, and the ball head seat 7 is opposite to the ball head The head 8 can freely rotate in all directions within the allowable space range, and the ball head 8 is welded on the co...

Embodiment 2

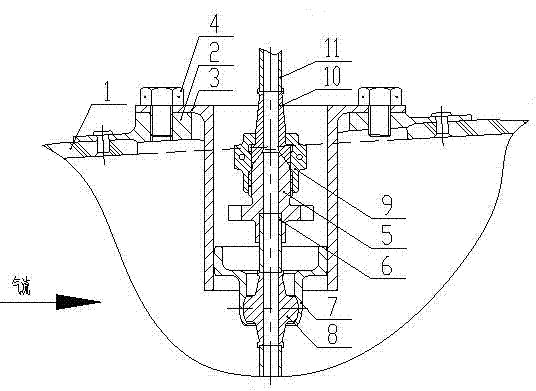

[0028] This embodiment provides a tooth-shaped floating seal structure for passing through the casing, which is characterized in that it includes a casing 1, a casing mounting seat 2, a lead-out pipe sleeve 3, bolts 4, an outer cone joint 5, Conduit 6, ball seat 7, ball head 8, extra nut 9, flat nozzle 10, conduit 11;

[0029] Among them: the outer cone joint 5 and the conduit 6 are welded together, which is the casing inner conduit assembly; the external nut 9, the flat nozzle 10, and the conduit 11 are welded together, which is the casing outer conduit assembly, and the casing mounting seat 2 is welded or riveted On the casing 1, the lead-out tube sleeve 3 is fixed on the casing mounting seat 2 by 8 bolts 4, and closed by the ball head 7 to make it integrated with the ball head 8, and the ball head 7 is opposite to the ball head 8 can freely rotate in all directions within the allowed space range, and the ball head 8 is welded on the conduit 6 .

[0030] There is a tighteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com