Flameproof test tank

A test tank and explosion-proof technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve problems such as failure, accident testing, and the failure of test personnel to discover and correct them in time, so as to achieve the effect of increasing the use height and making full and effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

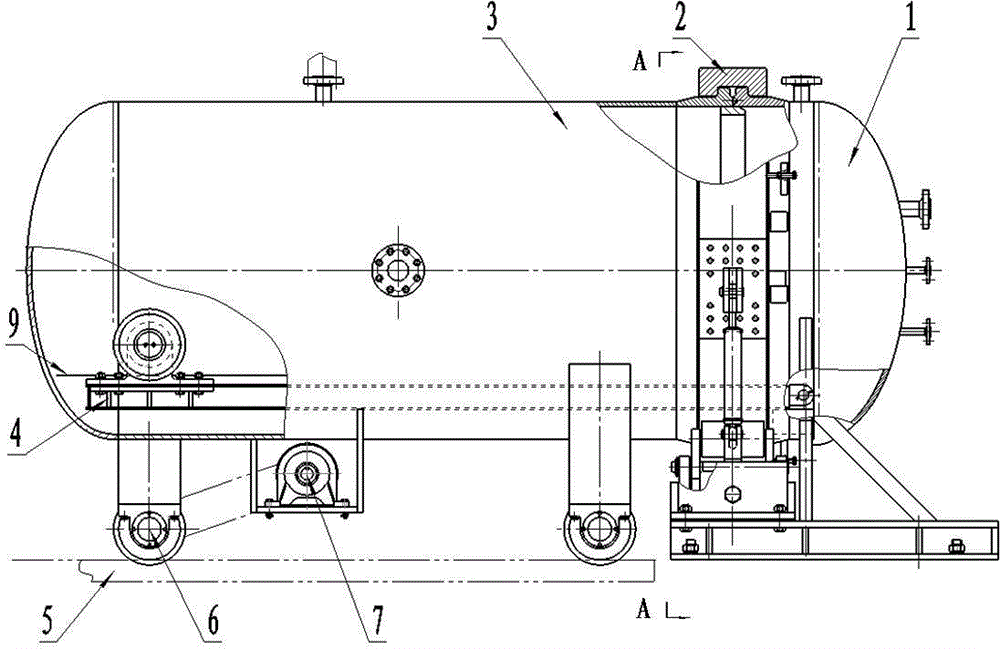

[0022] The test tank adopts a horizontal structure and is composed of a tank body, an end cover, a clamp, a bearing frame, an idler mechanism and a walking mechanism.

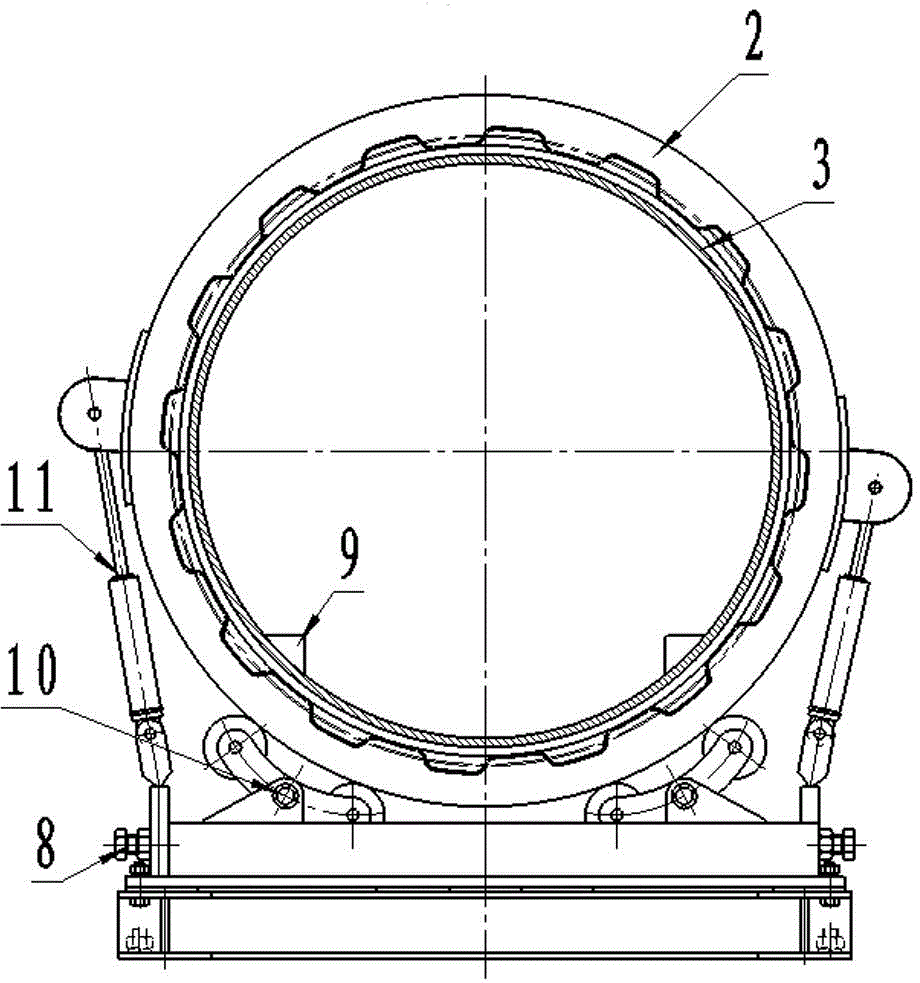

[0023] The tank body and the end cover are connected by a clamp. After the tank body and the end cover are fastened, turn the clamp to fasten the end cover and the tank body flange. The rotation of the hoop is realized by the push and pull of the left and right hydraulic cylinders. In order to ensure the centering and flexible rotation of the clamp, an idler mechanism is installed under the clamp, and the adjustment screw of the idler can adjust the horizontal and vertical positions of the clamp to make it coaxial with the tank body. Two sets of idler mechanisms are arranged, which are symmetrical to the longitudinal axis of the clamp 2. Each set of idler mechanisms 10 includes two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com