Parameter optimization control method of semiconductor advance process control

An advanced process control and optimal control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as changes in production process parameters, and achieve improved modeling capabilities, enhanced robustness and anti-interference performance, compensation for smooth drift and disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be explained below with reference to the accompanying drawings.

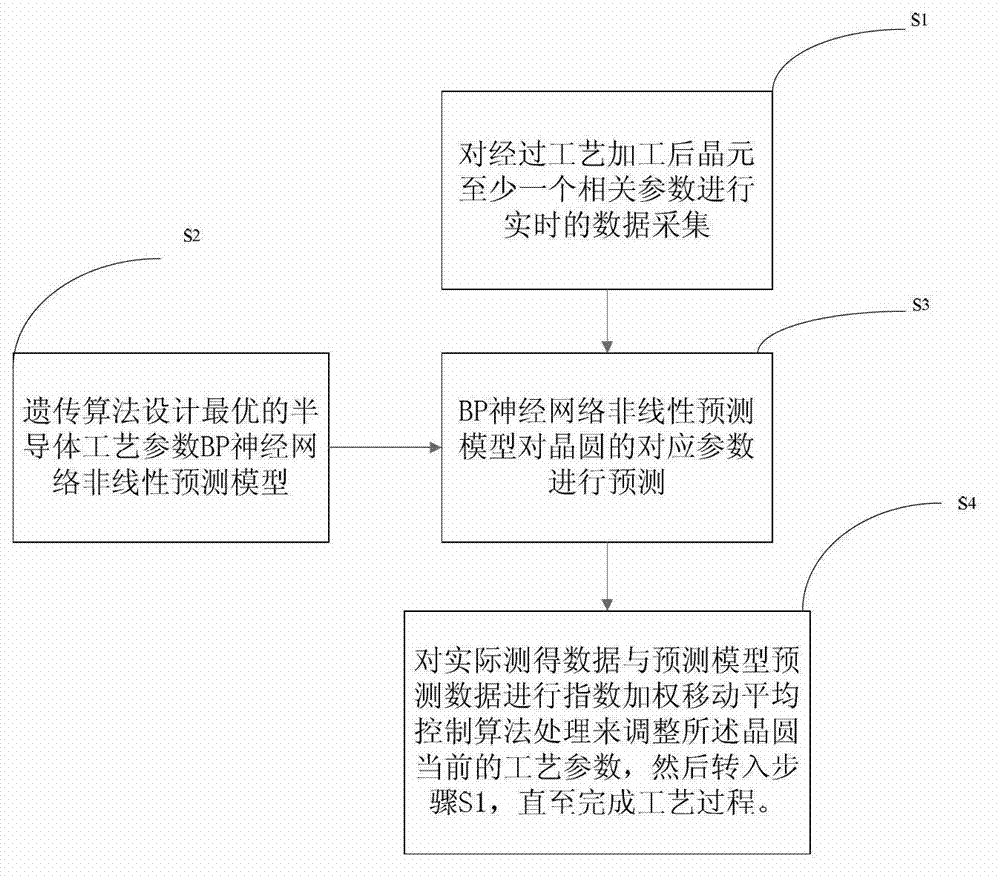

[0038] According to the scheme of the present invention, such as figure 1 As shown, the present invention provides a parameter optimization control method for semiconductor advanced process control, including the following steps: S1, real-time data collection of at least one related process parameter of the wafer after process processing; S2, using genetic algorithm to design the most Optimal semiconductor process parameters BP neural network nonlinear prediction model; S3, using the genetic algorithm to optimize the BP neural network nonlinear prediction model to predict the corresponding process parameters of the wafer; S4: the actual measured data and the prediction model prediction The data is processed by an exponential weighted moving average control algorithm to adjust the current process parameters of the wafer, and then transfer to step S1 until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com