Disk Motor And Electric Power Tool Equipped With The Same

A disc motor and electric current technology, which is applied in the direction of electric components, rotating collectors, and manufacturing motor generators, etc. It can solve the problems that the outer diameter of the steering gear disc cannot be made small, cannot be made large, and cannot reduce the substrate area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

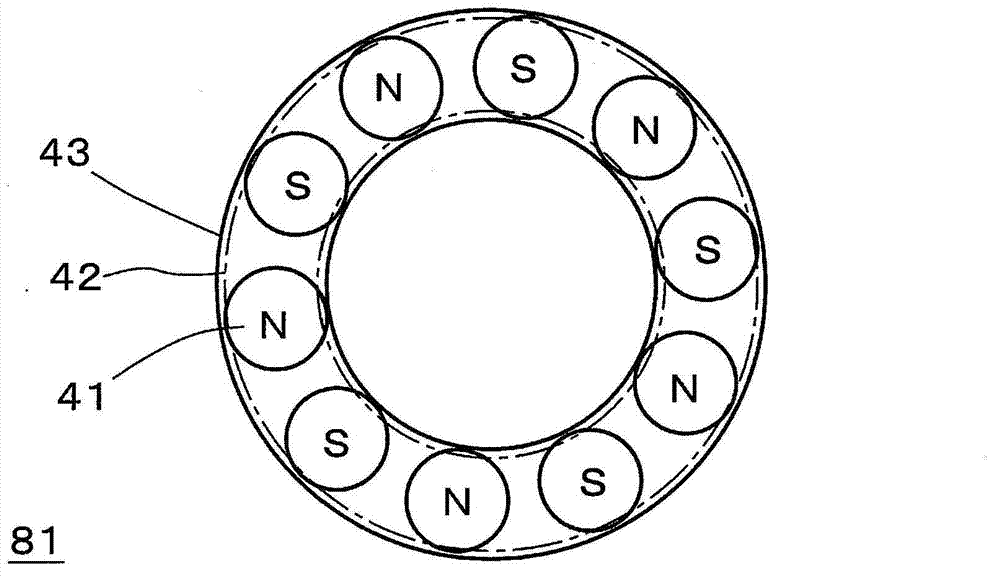

[0062] Figure 5A is a plan view showing electrode patterns on the rear surface side of the diverter disk according to the first embodiment; Figure 5B is a plan view of the communication pattern on the front surface side of the commutator disk viewed in perspective from the rear surface side, while omitting the electrode pattern and the insulating substrate; and Figure 5C is a plan view showing the front surface side of the steering gear disc. The diverter disk 100 is formed by providing a predetermined conductive pattern made of a conductive material such as copper on both surfaces of a disk-shaped insulating substrate having an opening formed at the center thereof. The insulating substrate is formed of, for example, an insulating resin such as a glass fiber reinforced epoxy resin substrate. Details of the conductive pattern will be described later.

[0063] Figure 6A is a plan view showing communication patterns on the rear surface side of the land according to the fi...

no. 2 example

[0078] Figure 7A is a plan view showing electrode patterns on the rear surface side of the diverter disk according to the second embodiment; Figure 7B is a plan view of the communication pattern on the front surface side of the commutator disk viewed in perspective from the rear surface side, while omitting the electrode pattern and the insulating substrate; and Figure 7C is a plan view showing the front surface side of the steering gear disc.

[0079] Figure 8A is a plan view showing communication patterns on the rear surface side of the land according to the second embodiment; Figure 8B is a plan view of the communication pattern on the front surface side of the land as seen through from the rear surface side, while omitting the communication pattern and the insulating substrate on the rear surface side; and Figure 8C is a plan view showing the front surface side of the land. Differences from the first embodiment will be mainly described below, and descriptions of ...

no. 3 example

[0089] Figure 9A is a plan view showing communication patterns on the rear surface side of the land according to the third embodiment; Figure 9B is a plan view of the communication pattern on the front surface side of the land as seen through from the rear surface side, while omitting the communication pattern and the insulating substrate on the rear surface side; and Figure 9C is a plan view showing the front surface side of the land.

[0090] In this embodiment, since the diverter disc 110 is equal to that of the second embodiment, illustration and description thereof are omitted. Differences from the second embodiment will be mainly described below, and descriptions of points common to the second embodiment will be appropriately omitted.

[0091] Such as Figure 9A As shown, a plurality of rear surface side first communication patterns 251 are provided on the rear surface of the land 200 . Such as Figure 9B and 9C As shown, a plurality of front surface side first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com