Electrostatic capacitor type pressure sensor and producing method thereof

A pressure sensor, electrostatic capacitance technology, applied in the fluid pressure measurement using capacitance change, fixing the capacitor terminal, measuring fluid pressure through electromagnetic components, etc., can solve the problems of difficult to obtain uniform detection accuracy, uneven distance, etc. The effect of uniform precision and small substrate area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

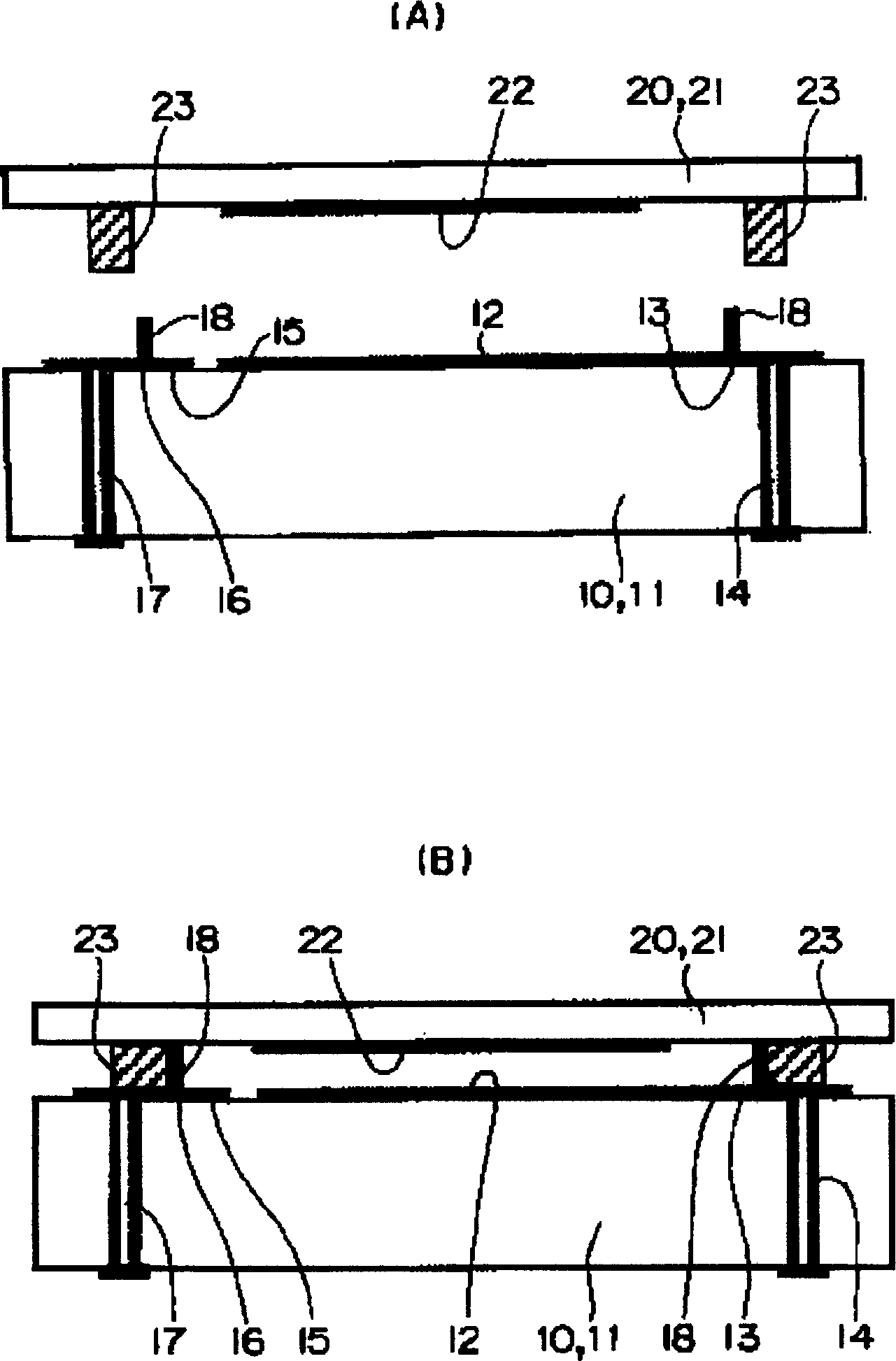

[0021] according to Figure 1 to Figure 6 The description relates to embodiments of the invention.

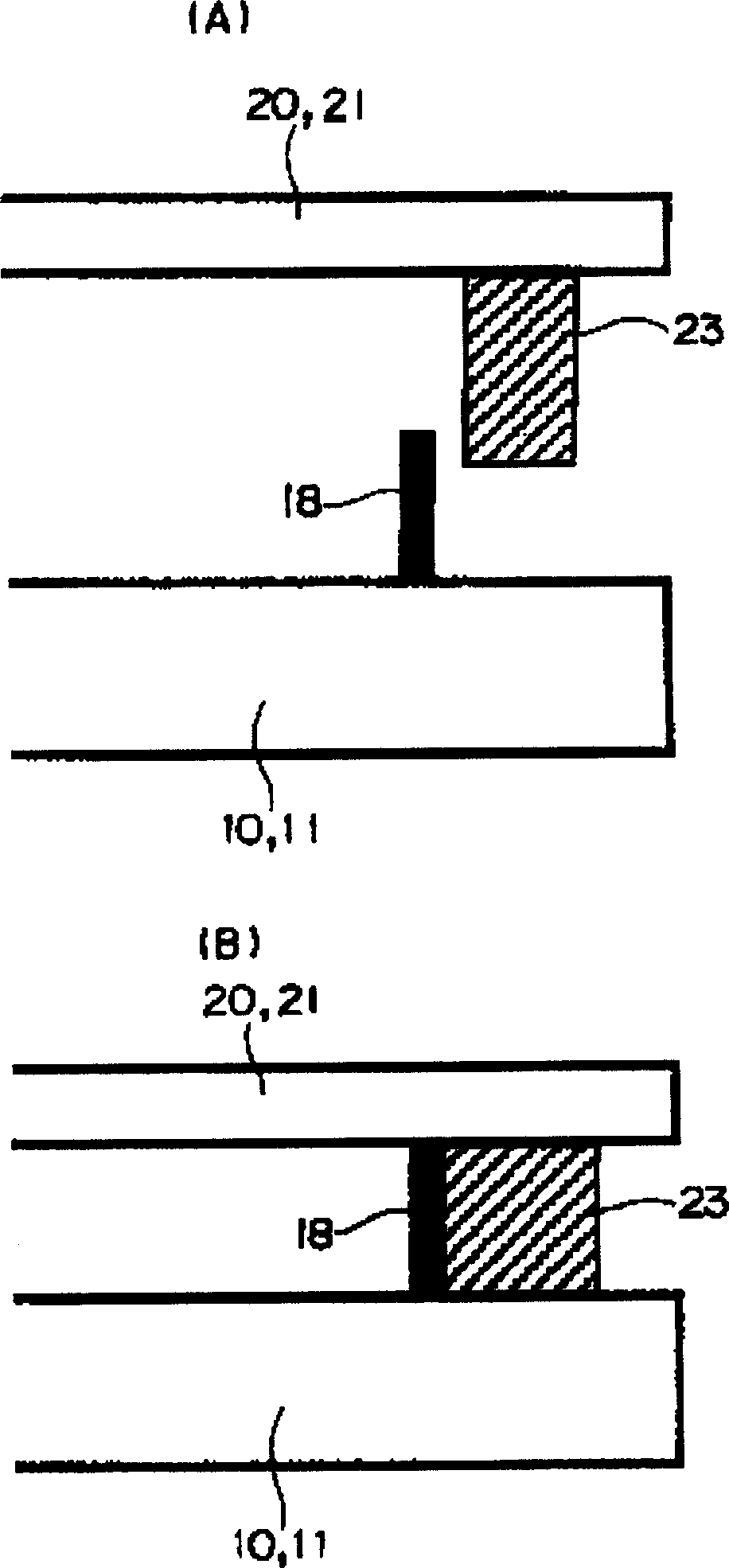

[0022] Such as Figure 1 to Figure 4 As shown, the first embodiment of the present invention relates to the case where the diaphragm 20 and the base 10 are joined together at a predetermined interval.

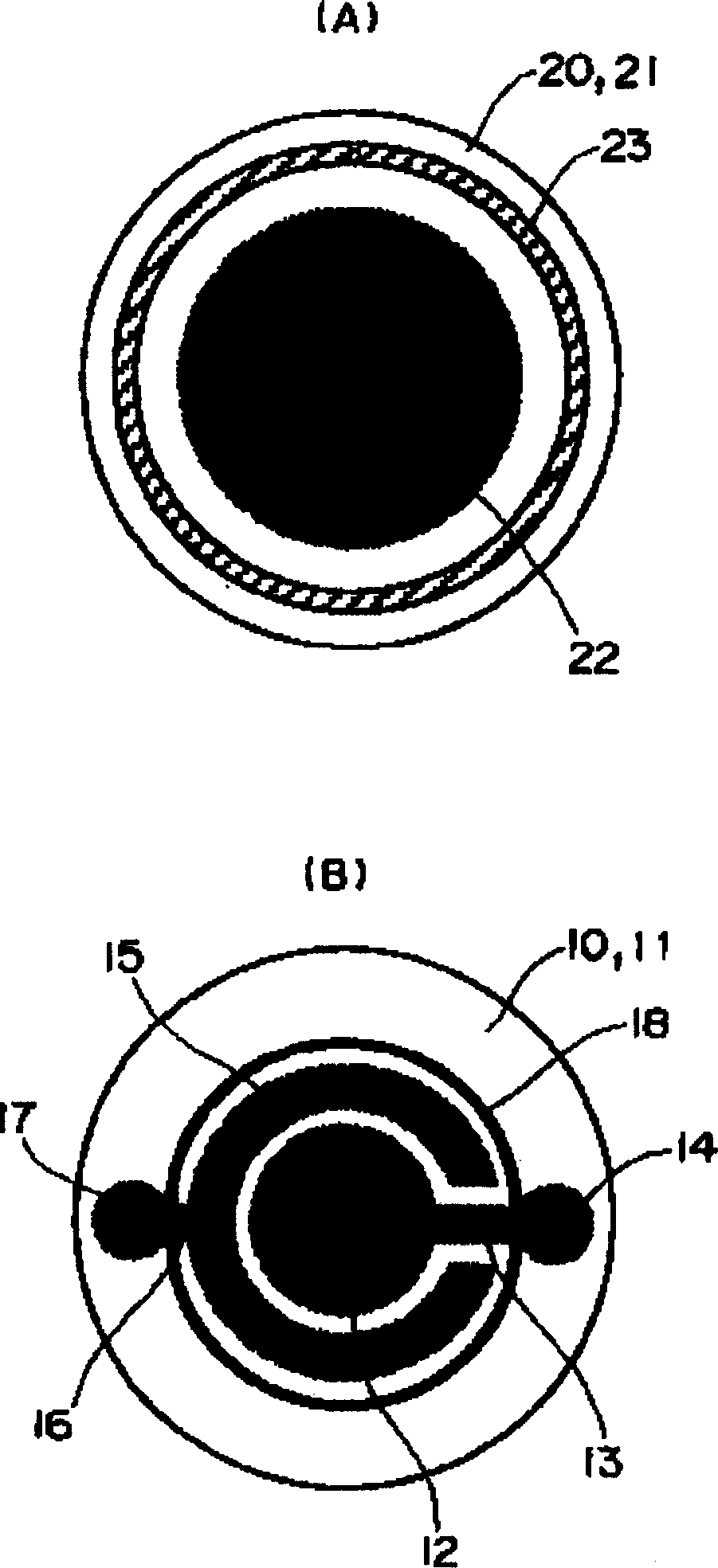

[0023] Such as image 3 As shown in B, the above-mentioned base 10 is provided with a first fixed electrode 12 at the center of the upper surface of a thick ceramic substrate 11 , and is connected to a through hole 14 through a lead wire 13 at the same time. Furthermore, the substantially C-shaped second fixed electrode 15 arranged around the first fixed electrode 12 is connected to the through hole 17 through the lead wire 16 . Therefore, an electrically conductive connection is formed from the underside of the ceramic substrate 11 through the through holes 14 and 17 , and the ring-shaped spacer 18 can be disposed around the second fixed electrode 15 .

[0024] The above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com