Electronic device and method of making the same

A technology of electronic devices and manufacturing methods, which is applied in the direction of radiation control devices, circuits, electrical components, etc., can solve the problems of large occupation and difficulty in miniaturization, and achieve the effect of reducing volume, facilitating miniaturization, and saving the area of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

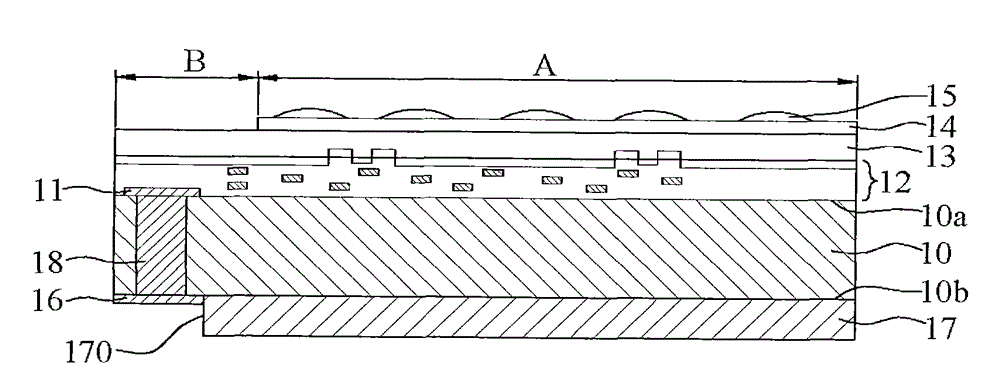

[0048] see Figures 2A to 2G , is a schematic cross-sectional view of the electronic device of the present invention and its manufacturing method, wherein, Figure 2G ’ and 2G” for Figure 2G other implementations.

[0049] Such as Figure 2A As shown, a silicon substrate 20 is provided.

[0050] Such as Figure 2B As shown, a photodiode layer 21 is formed on the silicon substrate 20, and the material of the photodiode layer 21 can be amorphous silicon (amorphous silicon).

[0051] Such as Figure 2C As shown, a wiring layer 22 is formed on the photodiode layer 21. The wiring layer 22 includes a plurality of stacked wirings 221. The wiring layer 22 has a plurality of transfer gates adjacent to the photodiode laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com