Thread end blowing-straightening device of micro motor coils

A technology of micro motors and coils, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of visual fatigue, increased labor intensity, and affect the production of enterprises, so as to solve the problems of visual fatigue, increase labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

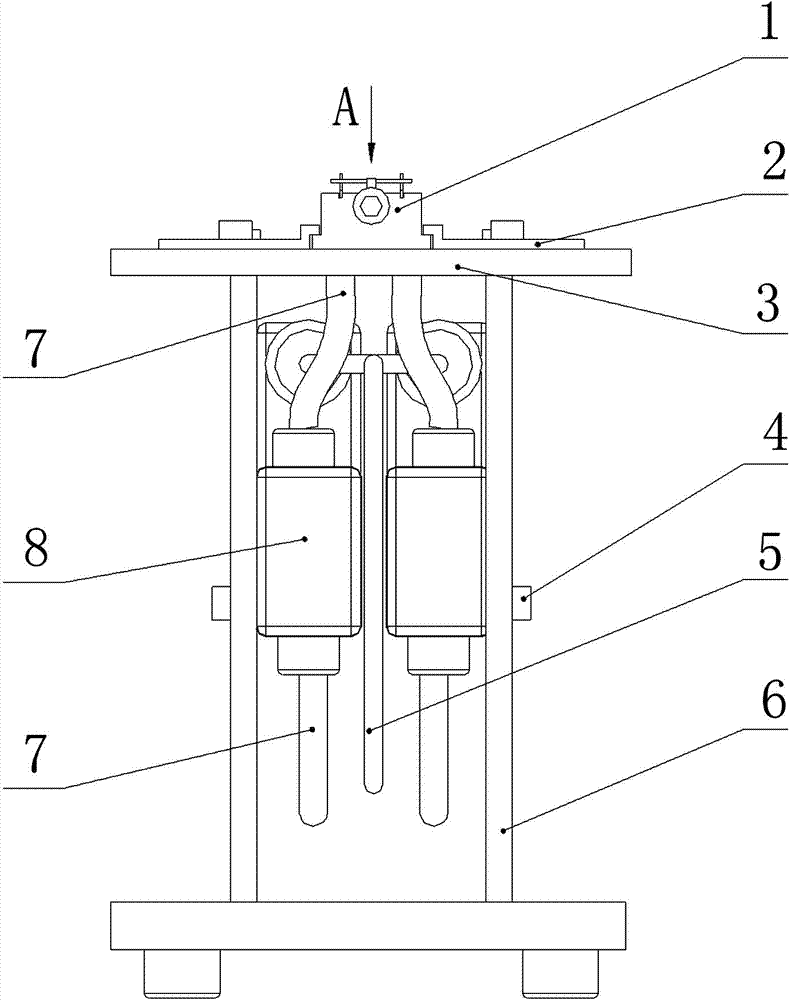

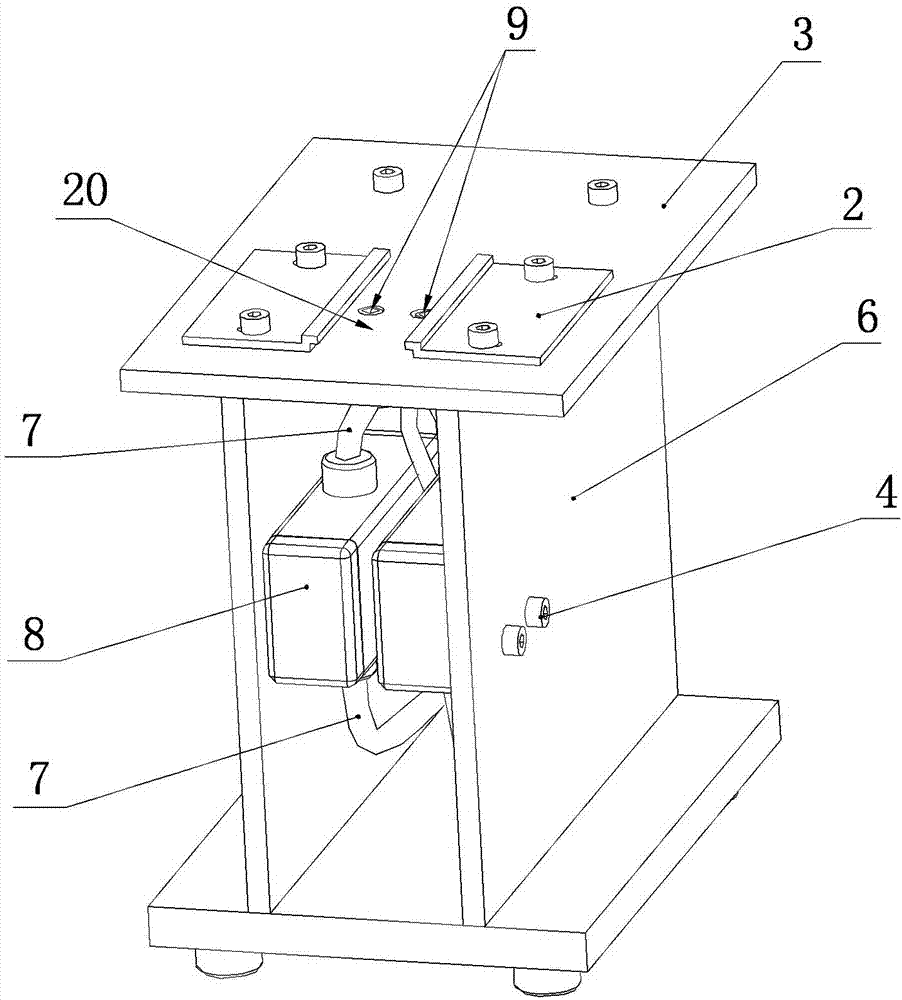

[0029] see Figure 1 to Figure 7 , an embodiment of a micro-motor coil wire end blowing device, which includes a clamp 1 for clamping the coil and a high-pressure air delivery device.

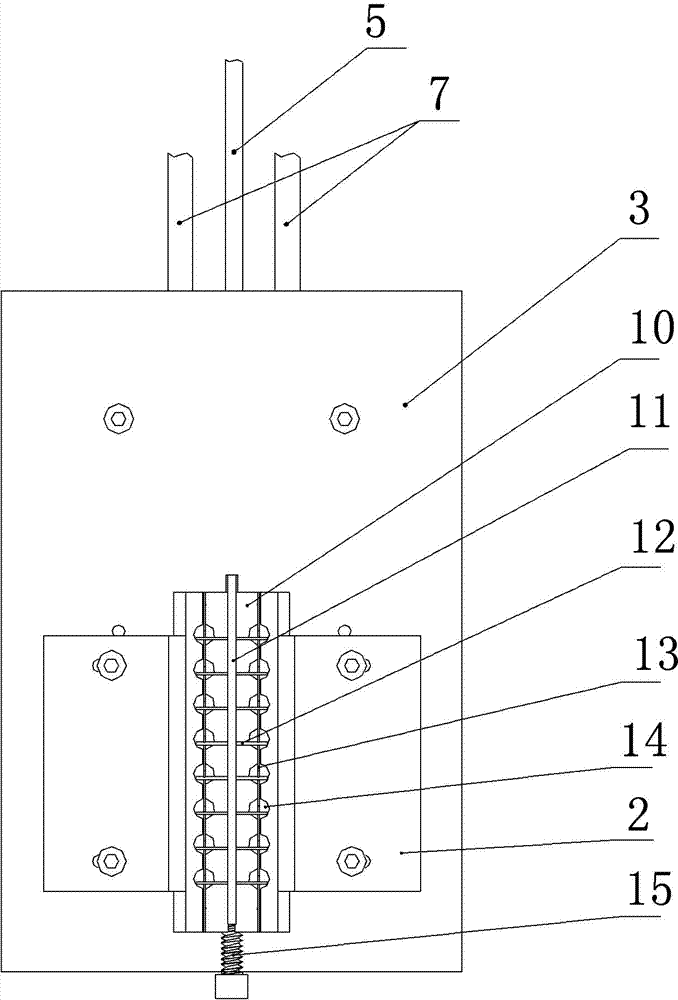

[0030]The clamp 1 for clamping a coil is composed of a base 10 and a clamping mechanism. The bottom surface of the base 10 is provided with a concave cavity 16, and the top surface of the base 10 is provided with a number of blowing holes 14 distributed in a queue, and these blowing holes 14 distributed in a queue are arranged in two rows, and the number of blowing holes 14 in the two rows is the same And the positions are symmetrical, the blowing holes 14 of each row are arranged at intervals along the longitudinal plane of the base 10, the present embodiment adopts 8 blowing holes in each row, and there are 16 blowing holes in two rows, and each blowing hole 14 communicates with the concave cavity 16, The central axis of each blowing hole 14 is perpendicular to the horizontal plane of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com