Engine block mold

A technology of engine cylinder block and casting mold, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve problems such as large scrap castings, and achieve the effect of reducing the generation of scrap castings and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

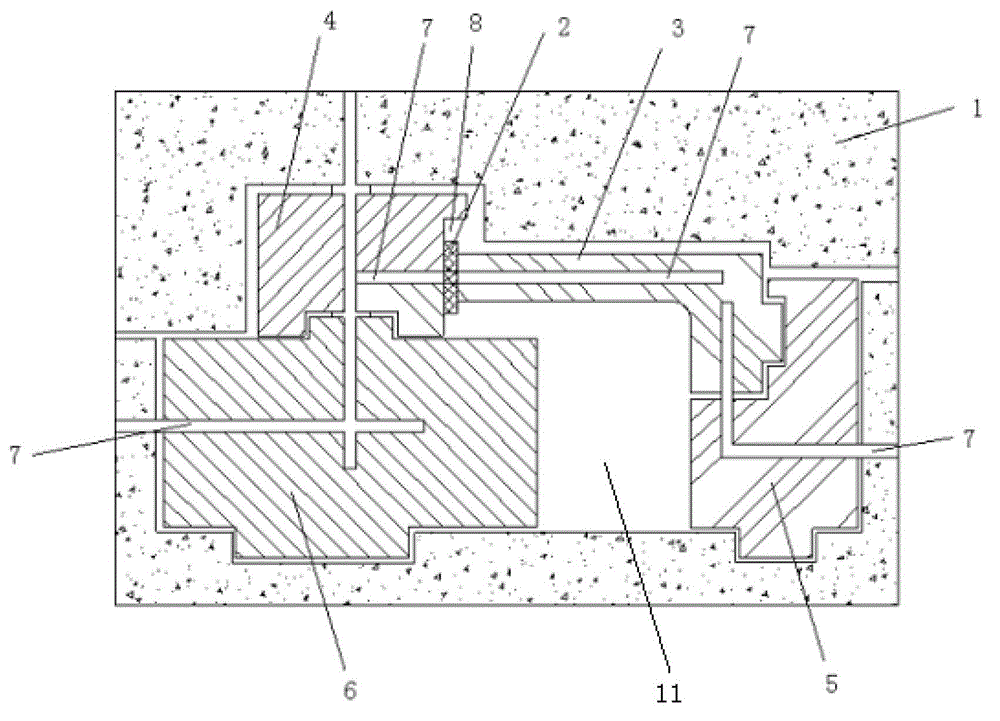

[0010] Embodiment: comprising a sand mold 1 provided with an inner cavity 11 and a water pump sand core 3 located in the inner cavity 11, a window sand core 4, a front end sand core 5 and a water jacket sand core 6, the water pump sand core 3, the window sand core 4. Both the front sand core 5 and the water jacket sand core 6 are provided with vent holes 7, and a process gap 8 is provided between the water pump sand core 3 and the window sand core 4, and a gasket 2 is provided in the process gap 8 . The gasket 2 is a polycrystalline mullite gasket.

[0011] When in use, since the gasket 2 seals the vent holes 7 of the water pump sand core 3 and the window sand core 4, molten iron cannot enter the vent holes 7, so the generation of waste castings is greatly reduced. Crystal mullite, the material has good compressibility, high temperature resistance and air permeability, so it can prevent molten iron from entering the vent hole 7, and ensure the normal exhaust of the vent hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com