Computer auxiliary centering installation and correction device and method for diffraction element

A computer-aided, diffractive element technology, used in auxiliary devices, tool holder accessories, turning equipment, etc., can solve problems such as large errors, inability to generate spherical center images with diffractive elements, and low efficiency, and achieve the effect of solving low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the purpose, technical solution and advantages of the device of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

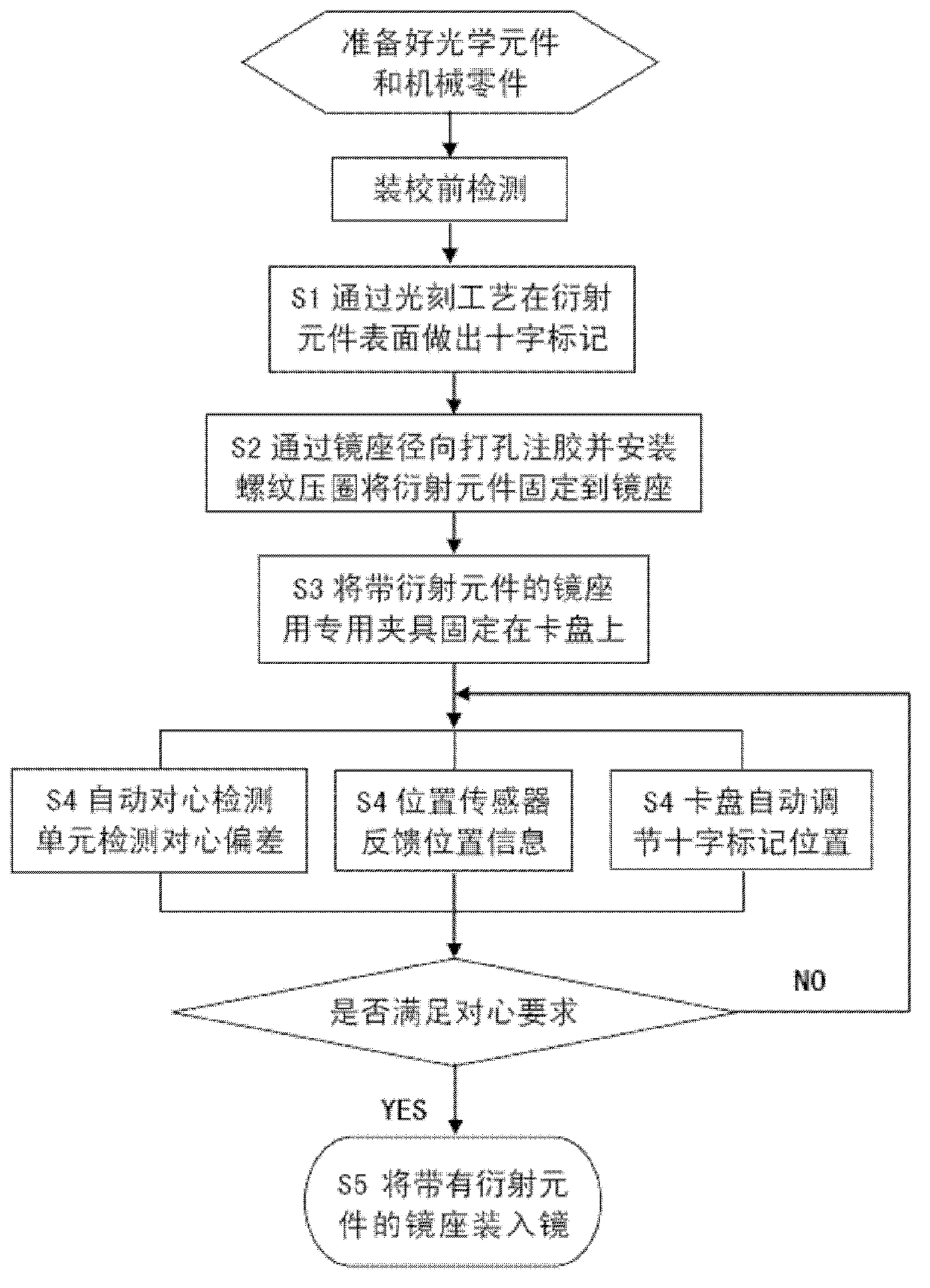

[0061]In the method and device of the invention, a computer is used to control the centering of the diffraction element, which improves the accuracy and efficiency of the centering alignment of the diffraction element, and realizes the automatic closed-loop feedback control of the centering alignment of the diffraction element.

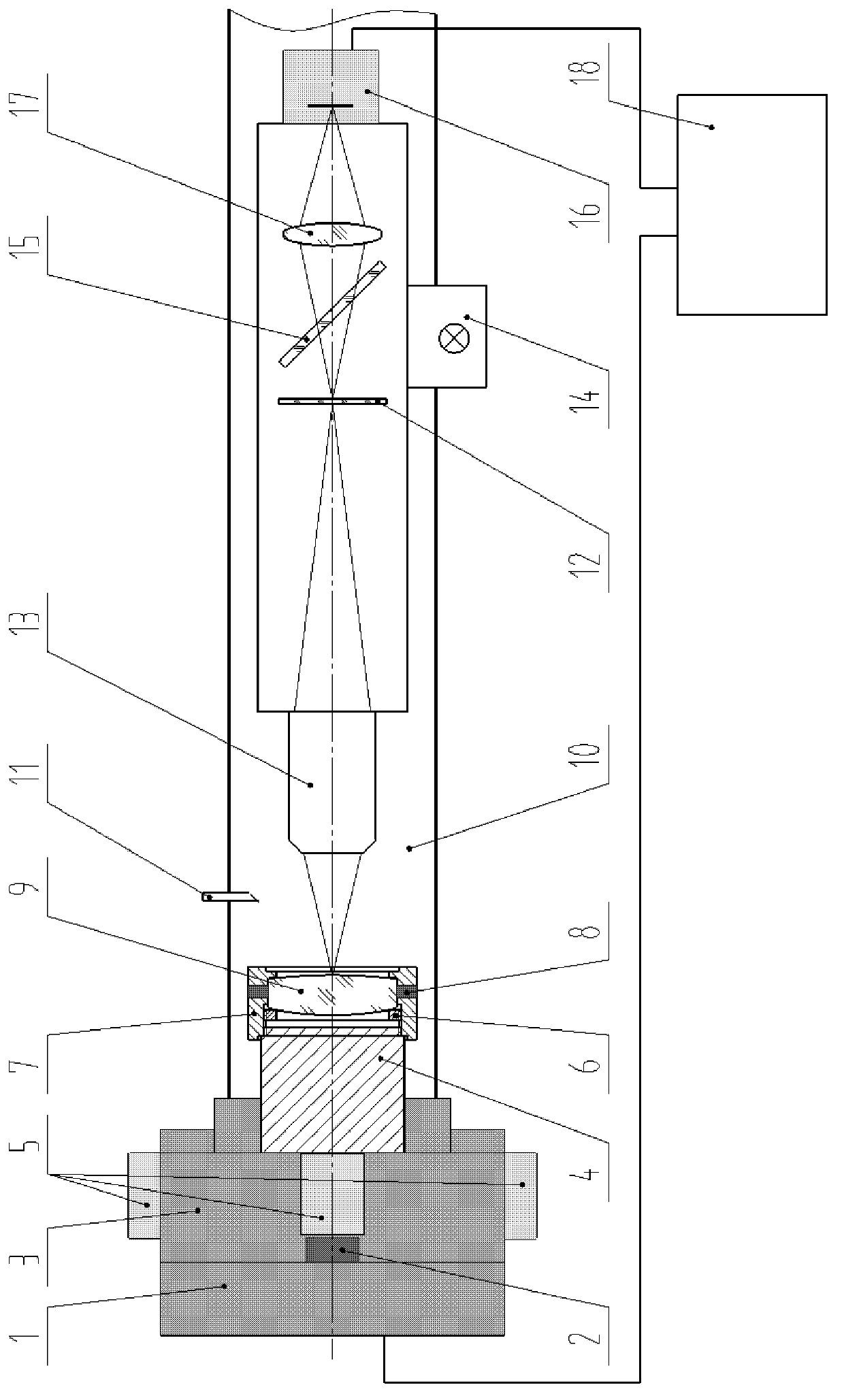

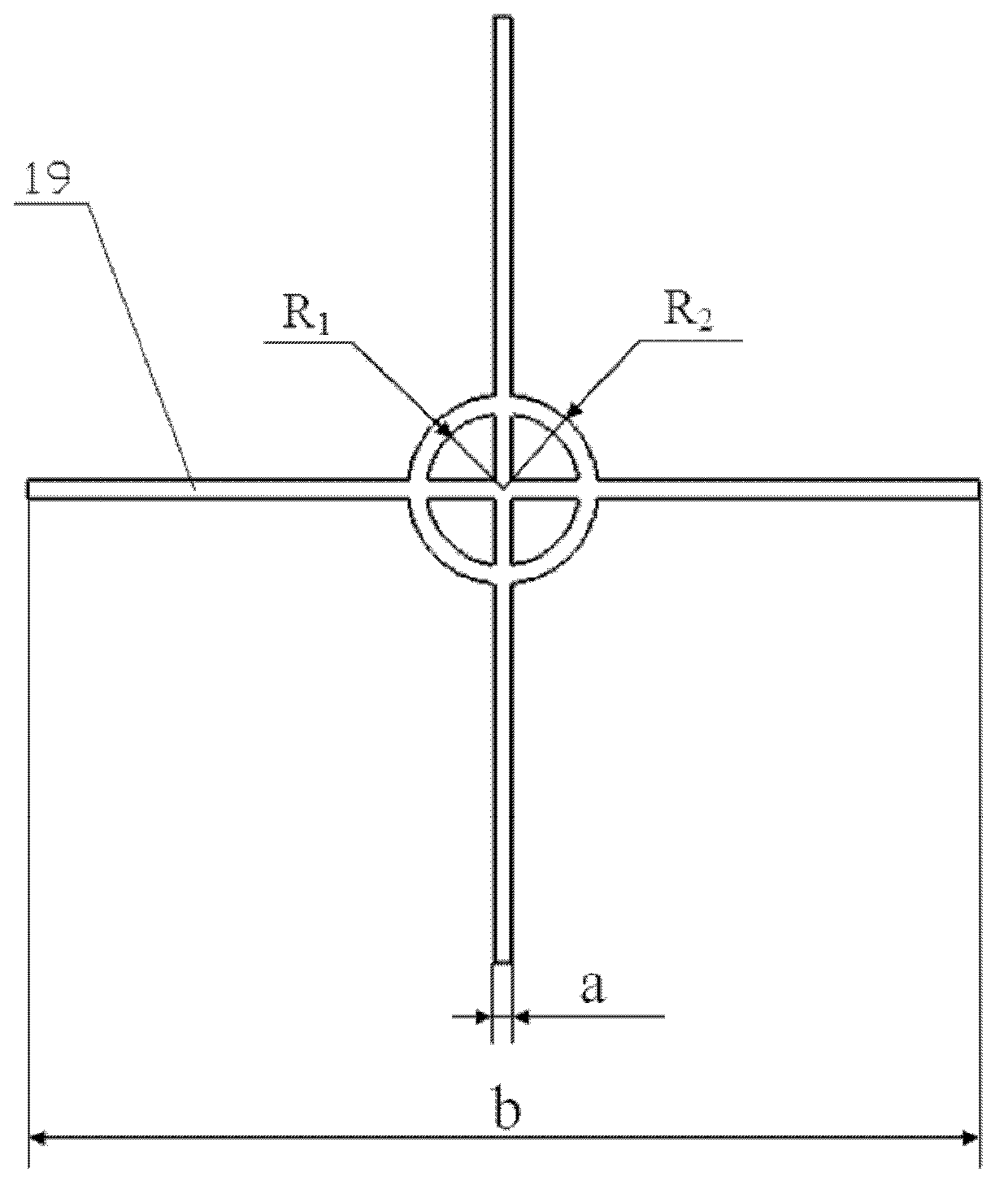

[0062] Improve and innovate the traditional optical lens lathe alignment method. A special cross mark for centering is processed in the center of the diffraction element by photolithography technology. The centering and calibrating device self-assembled by high-precision lathe, self-made centering detection system, electric inner ball head four-jaw chuck, driver, position sensor and computer is used as the main centering an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com