Wiper arm linkage system

A wiper and connected technology, applied in sliding contact bearings, vehicle maintenance, bearings, etc., can solve problems such as complex transportation and rising product costs, achieve economies of scale, and simplify supply chain logistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention relates to a coupling system, and more particularly to a coupling system for transmitting power from an electric motor to a wiper mechanism of a wiper device in a motor vehicle wiper system.

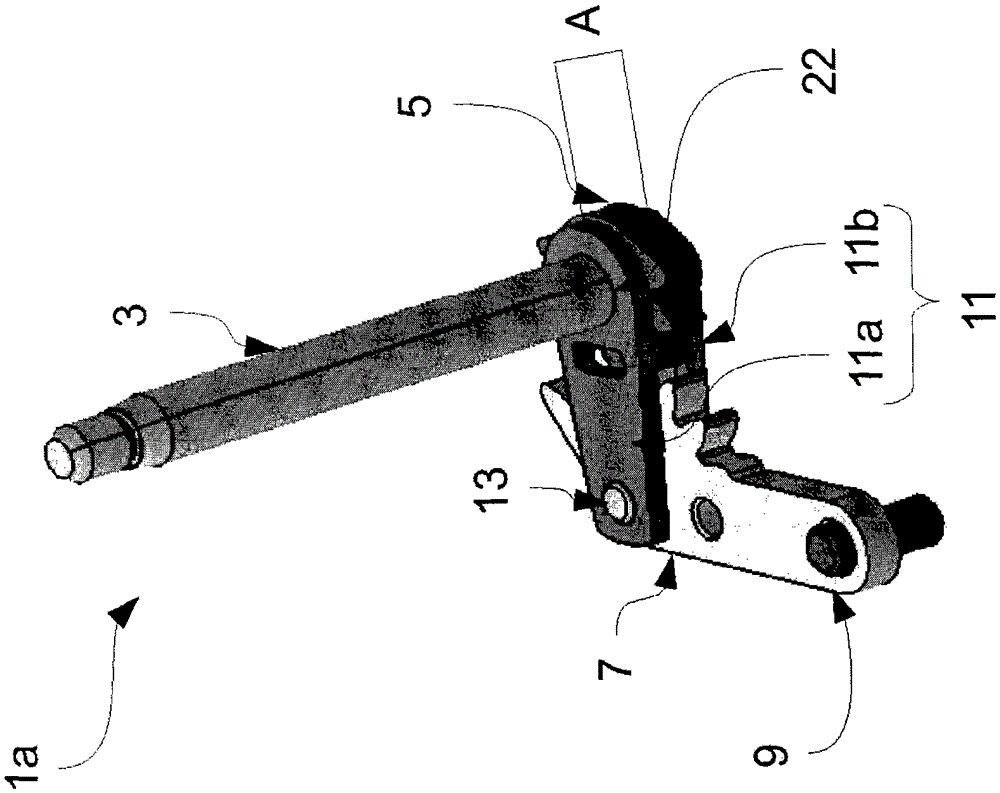

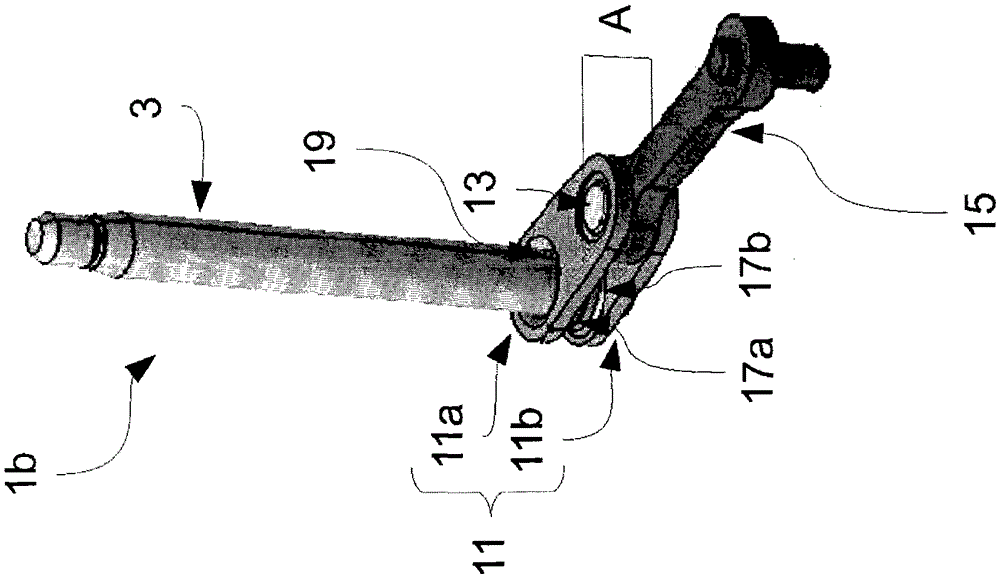

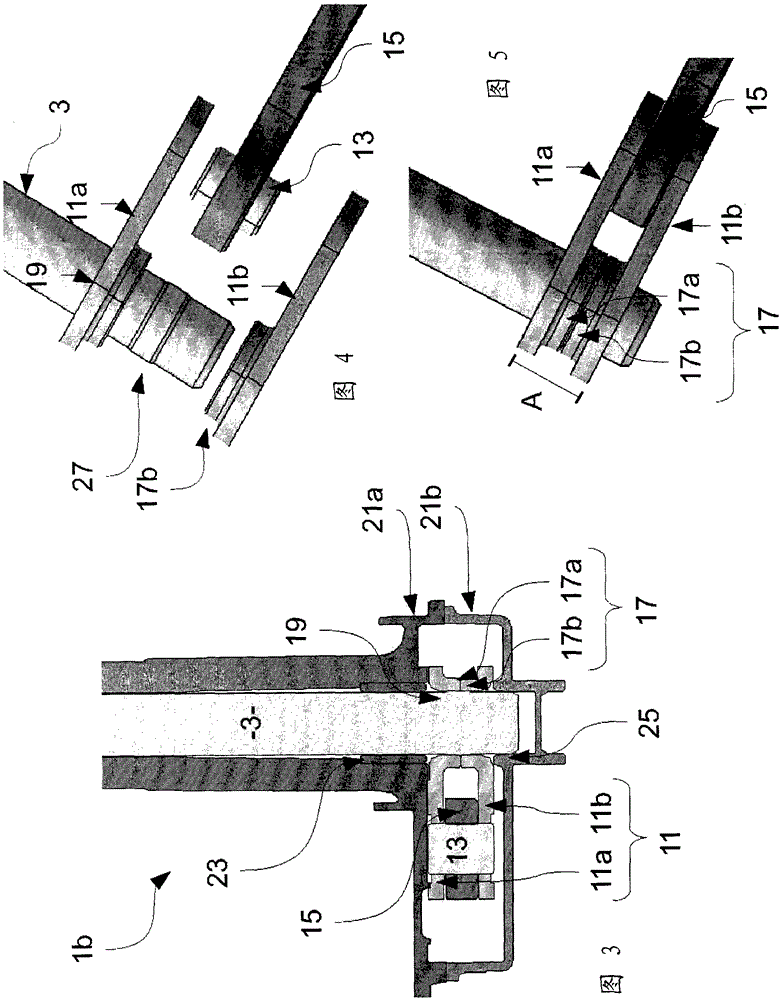

[0030] figure 1 A geared coupling system 1a is shown. Said coupling system comprises in particular a shaft 3 which is rotated by an electric motor (not shown), possibly via a transmission mechanism. The shaft 3 is fixedly attached to a first toothed wheel 5 which itself meshes with a toothed part of a second toothed wheel 7 (which forms the base of the arm 9 ), said The arm 9 is itself connected to a wiper mechanism of a wiper device (not shown).

[0031] The toothed wheels 5, 7 are held at intermeshing distance by the half-cranks 11a, 11b, which are two elongated metal plates perforated at their ends respectively to allow shaft 3 and the pivot 13 to which the second toothed wheel 7 forming the base of the arm 9 is hinged. Said pivot 13 comprises a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com