Water intake structure for water intake well

A technology for water intakes and water intake wells, applied in water supply devices, drinking water devices, buildings, etc., can solve problems such as filter clogging, clogging, deterioration of filter water collection efficiency, etc., and achieve the effect of preventing loss and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings.

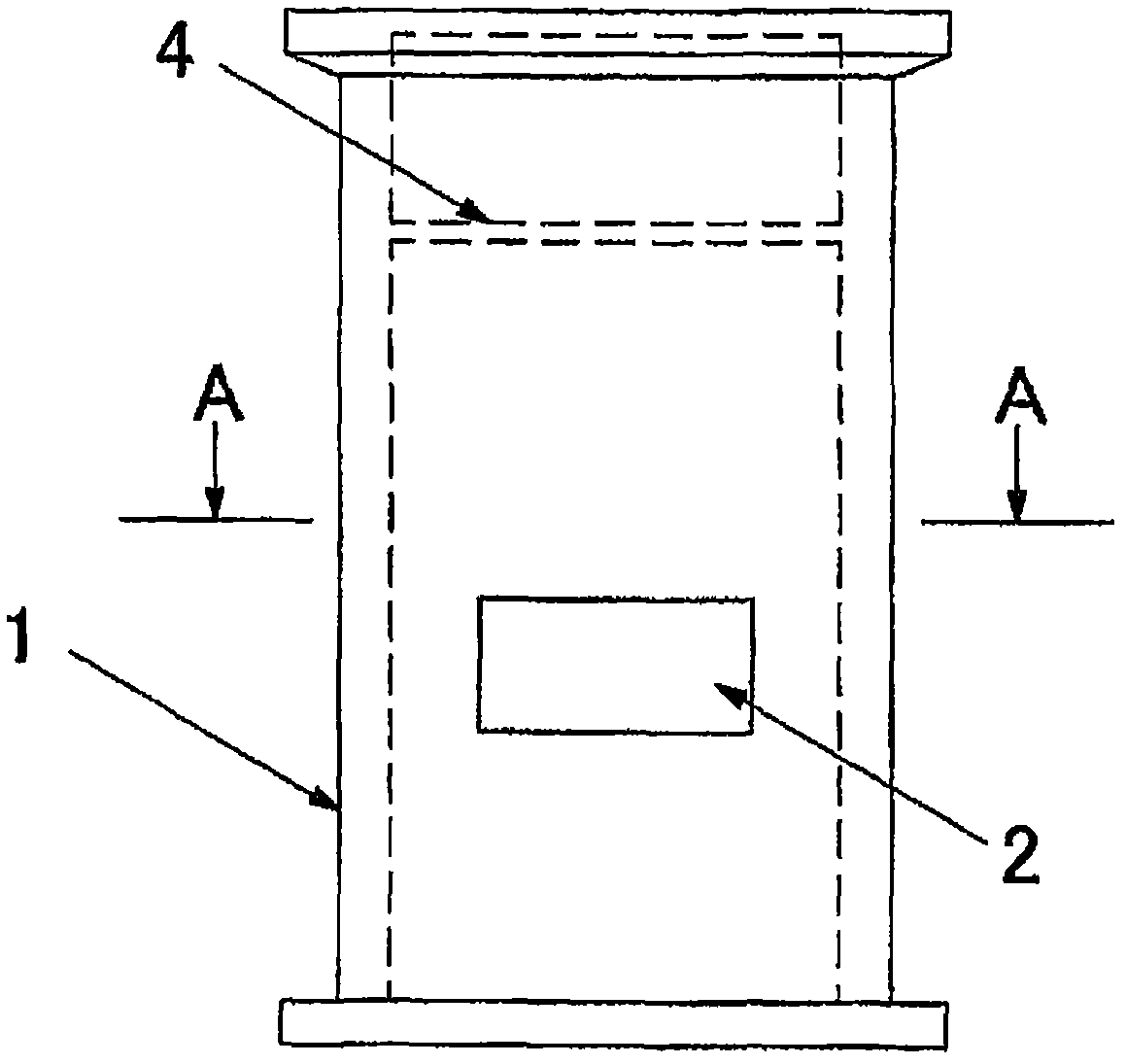

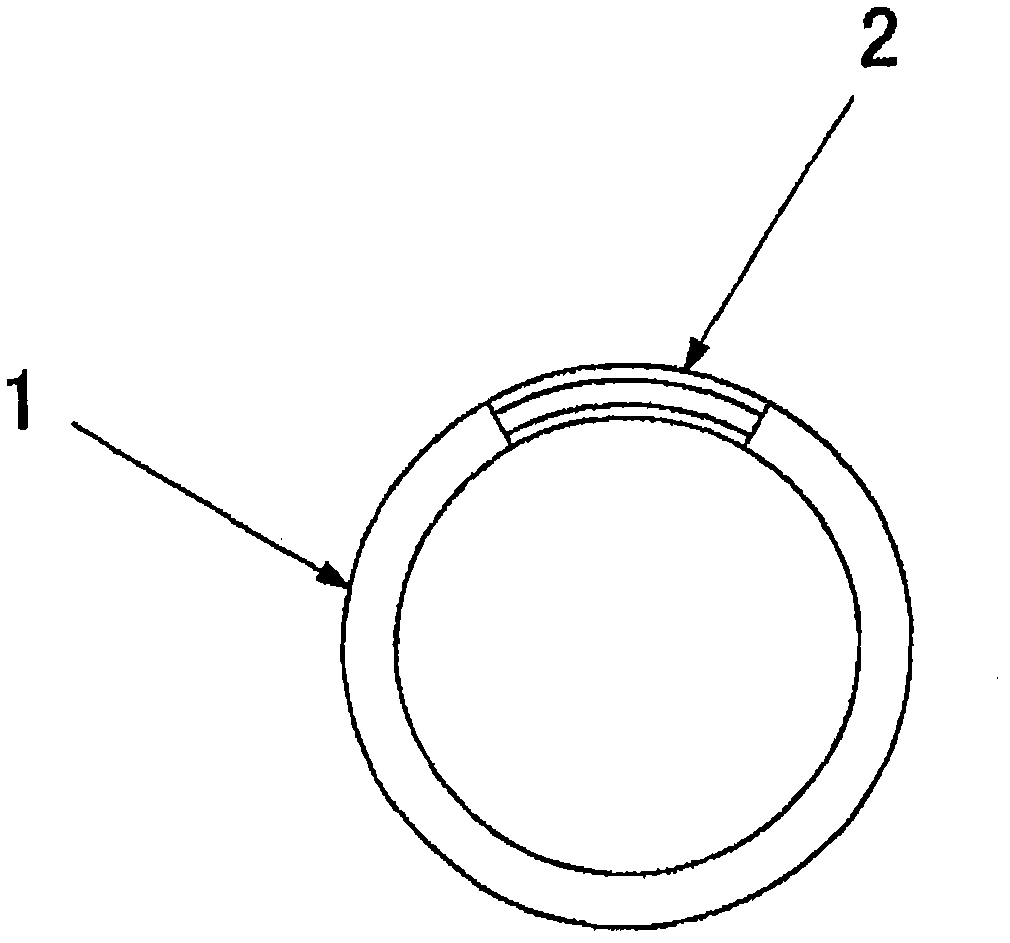

[0030] exist figure 1 and figure 2 Among them, a water intake well 1 with an elliptical cross section is formed into a cylindrical shape with an elliptical cross section by materials such as concrete or steel, and a substantially rectangular water intake 2 in a front view is provided at the lower part thereof. Mark 4 is an intermediate gangway for workers to use during construction. In this embodiment, the water intake is formed at a predetermined height on a part of the peripheral surface of the water intake well, but may be formed over the entire circumference of the water intake well. The diameter of the water intake well 1 is usually 2 m to 10 m, but it is not limited thereto.

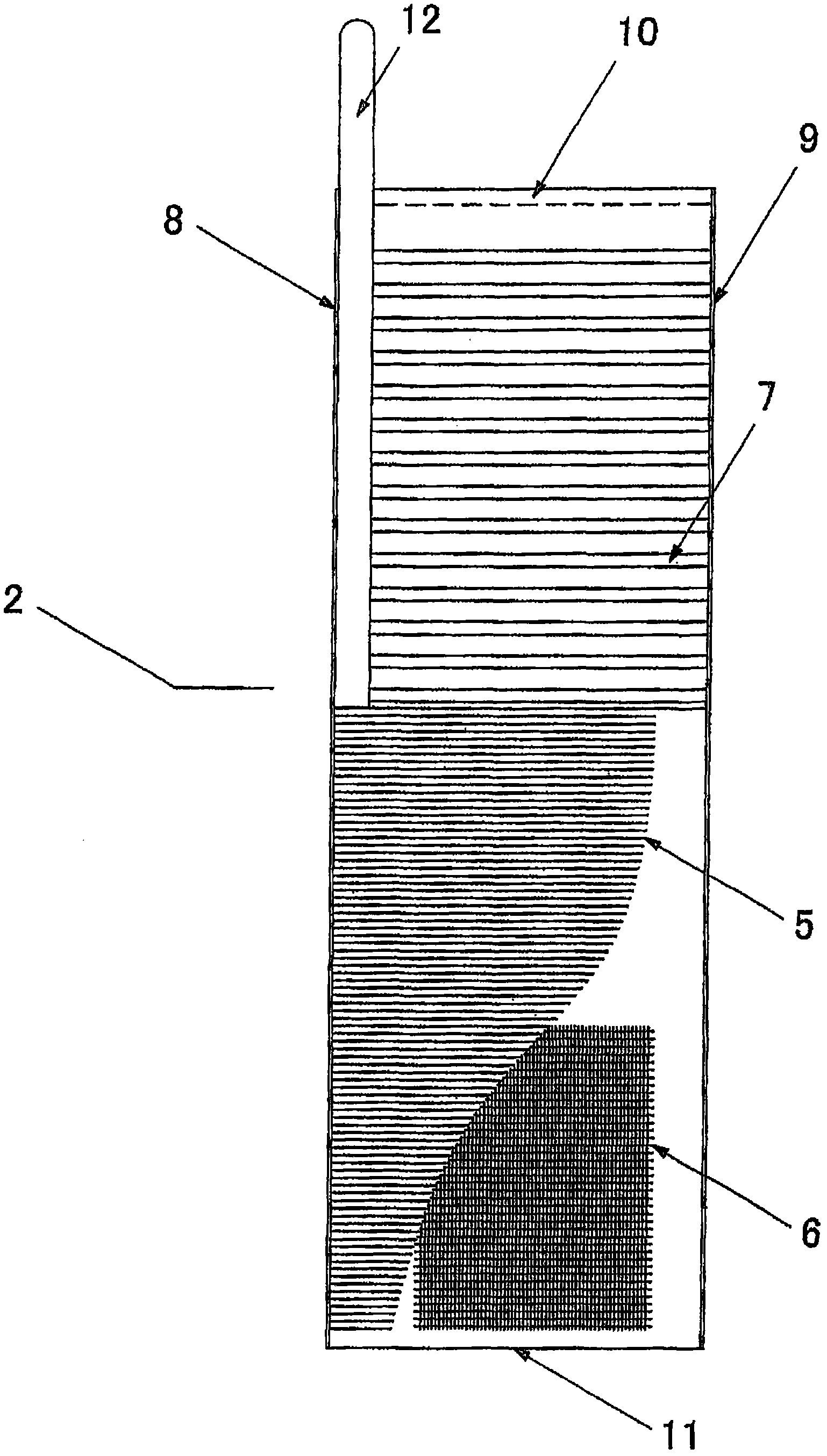

[0031] Such as image 3 As shown, viewed from the outside of the water intake well to the inside, the water intake 2 is equipped with a filter protection pipe 5, a filter 6, and a backwash pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com