A highly integrated cylindrical thermoelectric power generation noise reduction device

A thermoelectric power generation, highly integrated technology, applied in muffler devices, exhaust devices, generators/motors, etc., can solve the problems of uncontrollable working conditions of thermoelectric modules, large overall device volume, and large size in the width direction, so as to improve fuel efficiency. Economical, high energy utilization, effect of reducing exhaust gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

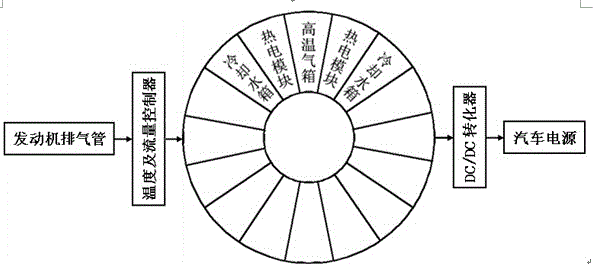

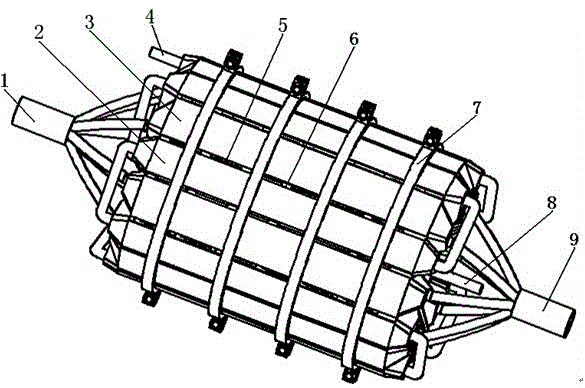

[0029] figure 2 Shown is a schematic diagram of the external structure of the highly integrated cylindrical thermoelectric power generation and muffler device of the present invention, which mainly includes a thermoelectric power generation device and a clamping device. The highly integrated cylindrical thermoelectric power generation muffler of the present invention comprises n identical independent hollow middle sections close to fan-shaped cylindrical high-temperature air boxes 3, and n identical independent hollow middle sections close to fan-shaped Column cooling water tank 2, thermoelectric module 5, heat insulation layer 6 and fastening device 7; the radius of the cross-sectional sector of the cooling water tank 2 is greater than the radius of the cross-sectional sector of the high-temperature gas tank 3, so as to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com