Unit nozzle for organizing combustion of large flow medium and low calorific value fuel

A low calorific value, high flow technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of low calorific value, low Wobbe index, high fuel reactivity, and achieve enhanced inscribed orientation and efficient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

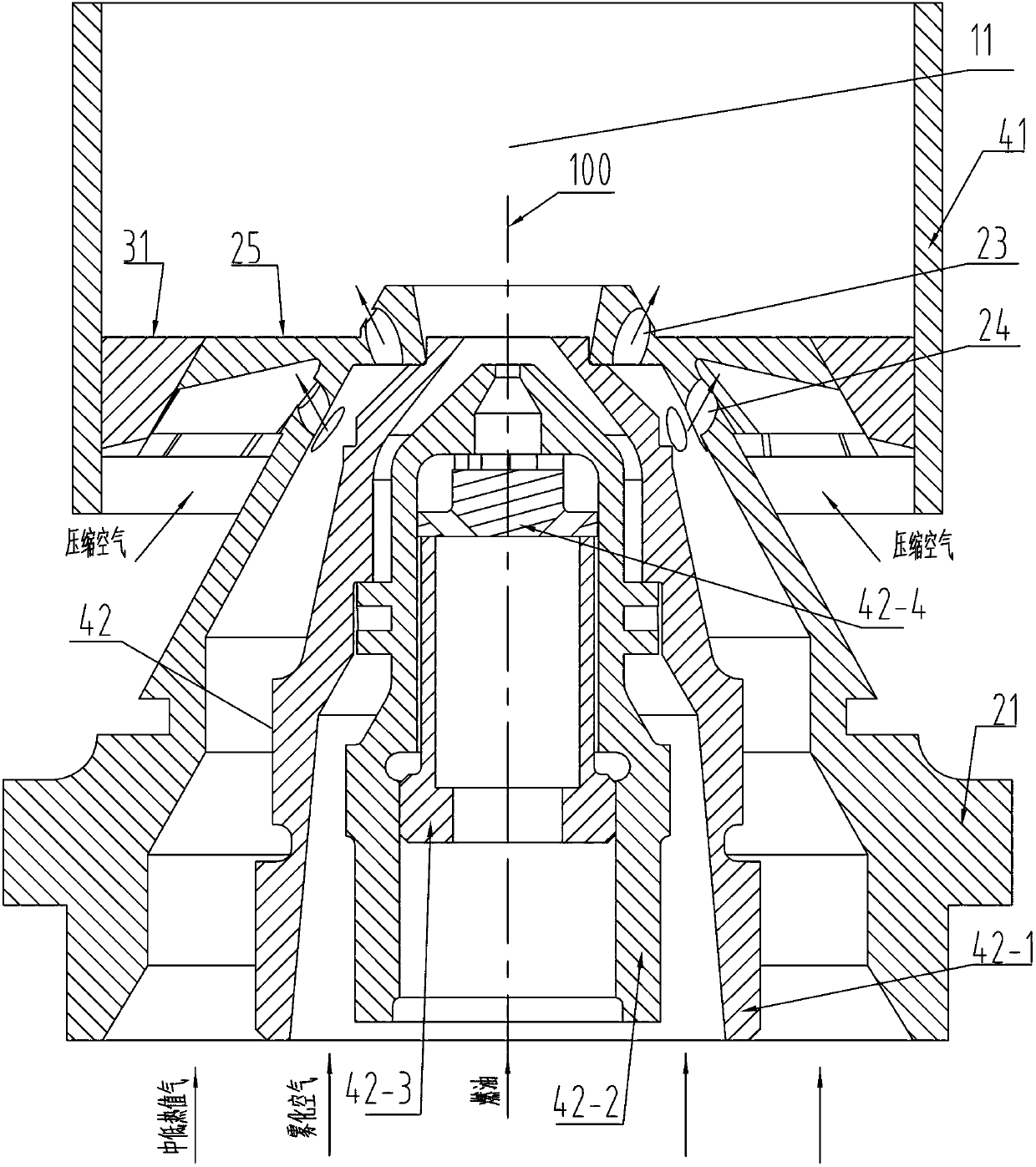

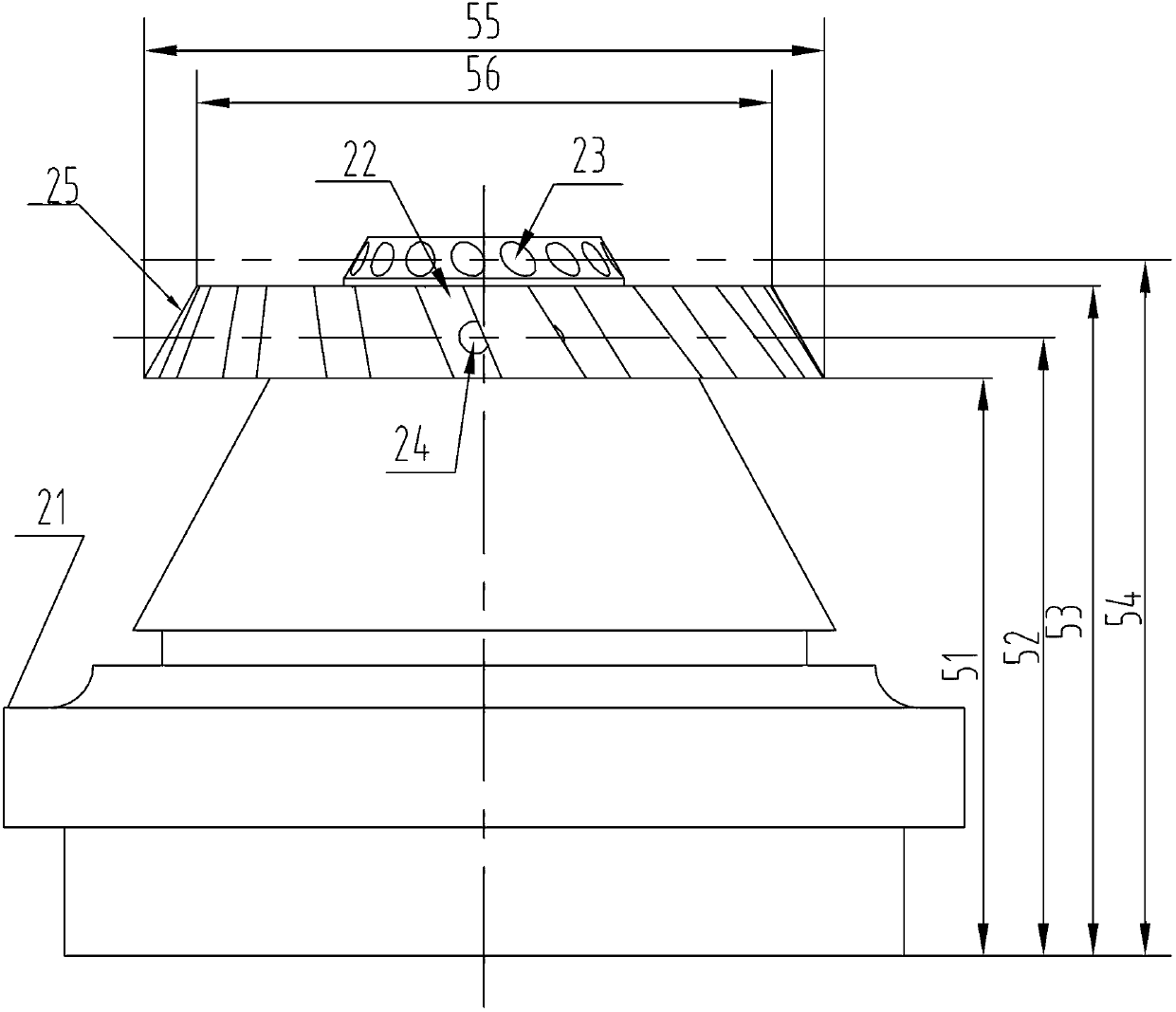

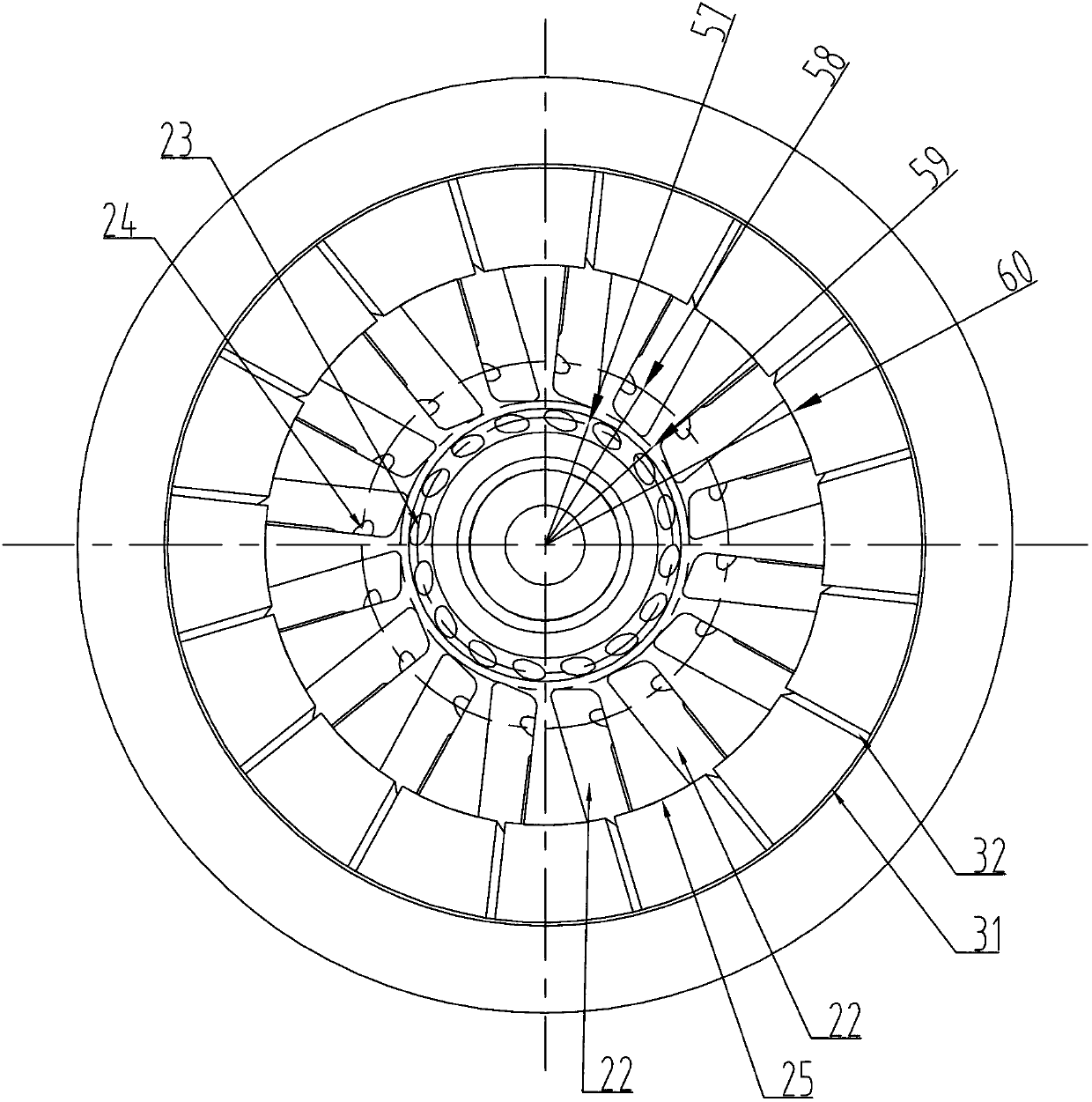

[0009] Specific implementation mode one: as Figure 1~4 As shown, the unit nozzle used to organize the combustion of medium and low calorific value fuels in this embodiment includes a central oil nozzle 42, and the unit nozzle also includes a conical shell 21, a vane shroud 31 and a sleeve 41. The oil nozzle 42 is placed in the conical housing 21 and the two are coaxial. The inner wall of the outlet end (small end) of the conical housing 21 and the outer wall of the outlet end (small end) of the core oil nozzle 42 are clamped together. The outer wall of the outlet end is provided with a conical shell air cyclone 25, the outer surface of the conical shell air cyclone 25 is tapered and consistent with the tapering direction of the conical shell 21; the blade crown 31 is fixed on the cone The outer edge of the outlet end of the air cyclone 25 of the shaped shell, the two are coaxial, and the end faces are flush; the outlet end of the conical shell 21 is placed in the casing 41 an...

specific Embodiment approach 2

[0013] Specific implementation mode two: as Figure 1~4 As shown, the central oil nozzle 42 in this embodiment includes an atomizing air nozzle housing 42-1, an oil nozzle housing 42-2, a bracket 42-3 and a swirl sheet 43-4, and the atomizing air nozzle housing 42 -1 and the oil nozzle housing 42-2 are conical in shape, the oil nozzle housing 42-2 is placed in the atomizing air nozzle housing 42-1 and the gap between the two is the atomizing air channel, and the rotary The flow piece 43-4 is installed on the outlet end of the oil nozzle housing 42-2 through the bracket 42-3. The outlet spray is mixed with atomizing air. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: as Figure 1~4 As shown, in this embodiment, the first set of circumferentially spaced fuel openings 23 and the second set of circumferentially spaced fuel openings 24 are oriented obliquely with respect to the centerline 100 of the conical housing 21 at a jet angle θ 1 Inject fuel, jet angle θ 1 between 10° and 30°. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com