Detection method for X ray of boiler tube panel

A detection method and X-ray technology, applied in the direction of using radiation for material analysis, can solve the problems of low degree of automation, low efficiency, and inability to guarantee accuracy, and achieve the effect of efficient operation and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

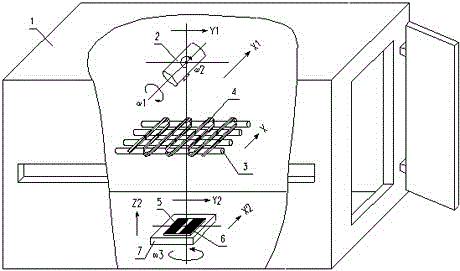

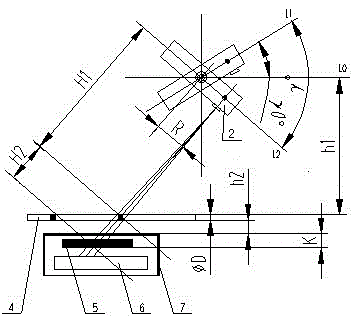

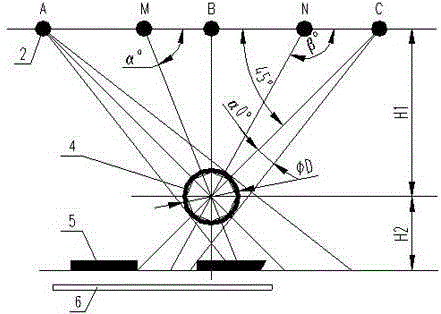

[0021] Such as figure 1 , figure 2 , image 3 As shown, the present invention is an X-ray detection method for boiler furnace tube screens, and its steps are:

[0022] (1) Tilt the X-ray machine (2) along the movement direction (ω2) of the designed tilt axis to the tilt angle position (γ0) of the X-ray machine (2) when the X-ray machine (2) and the panel (6) are aligned horizontally , Make sure that the beam exit of the ray is parallel and directly opposite to the panel (6);

[0023] (2) Deflection of the X-ray machine (2) to the reference of the X-ray machine (2) along Y1, the angle between the center of the beam exit of the machine and the center of the tube panel steel and the reference (α)=45 °, confirm that the ray beam is perpendicular to the panel; Y1 is the moving direction of the X-ray machine (2) parallel to the plane of the conveyor line and perpendicular to the plane of the conveyor line;

[0024] (3) Press the up / down button on the panel (6), the panel (6) will drop t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com