In-situ test method for buried pipeline across faults

A technology for in-situ testing and buried pipelines, which is applied in the field of cross-fault buried pipeline tests and test devices for testing reverse fault action in in-situ tests of cross-fault buried pipelines, and can solve problems such as ignoring the effects of pipeline joint connections Achieve the effects of convenient loading method and reliable and effective analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

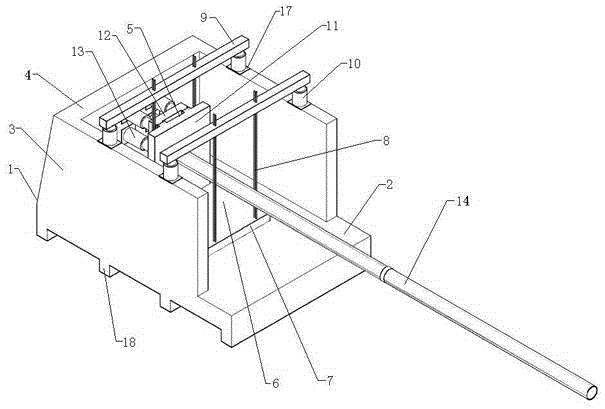

[0035] Such as Figure 1-7 Shown: an in-situ test method for buried pipelines across faults, the steps used in the test method are as follows:

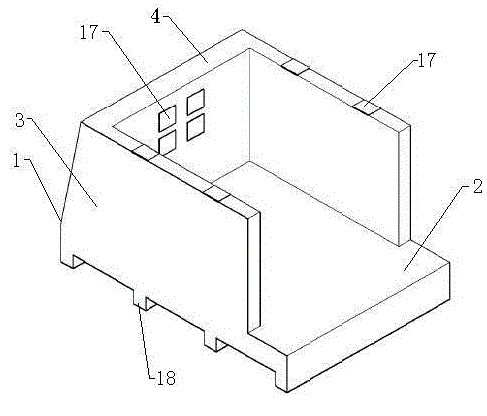

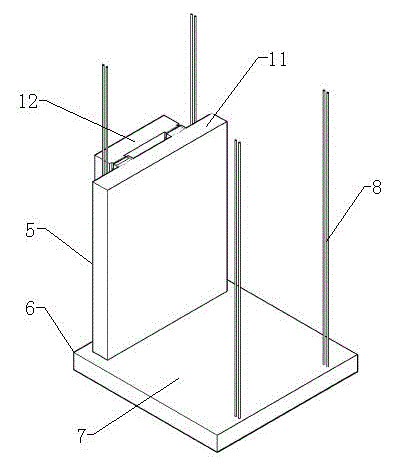

[0036]A. Select the test site and pour the reaction force device 1, wherein the reaction force device 1 includes the integrated reaction force platform 2, the vertical reaction force wall 3, the horizontal reaction force wall 4 and the foundation beam 19, wherein the vertical reaction force Wall 3 and horizontal reaction force wall 4 also can adopt vertical reaction force frame and horizontal reaction force frame, two vertical reaction force walls 3 are respectively positioned at the both sides of horizontal reaction force wall 4 and vertical reaction force wall 3 and horizontal reaction force wall The force wall 4 is arranged vertically on the upper surface of the counter force pedestal 2 in a "匚" shape, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com