a method of exposure

An exposure method and light source technology, applied in the field of exposure, can solve the problems of etching failure, scrapped semiconductor devices, difficult to overcome the diffraction phenomenon of lithography, etc., and achieve the effect of preventing the diffraction phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

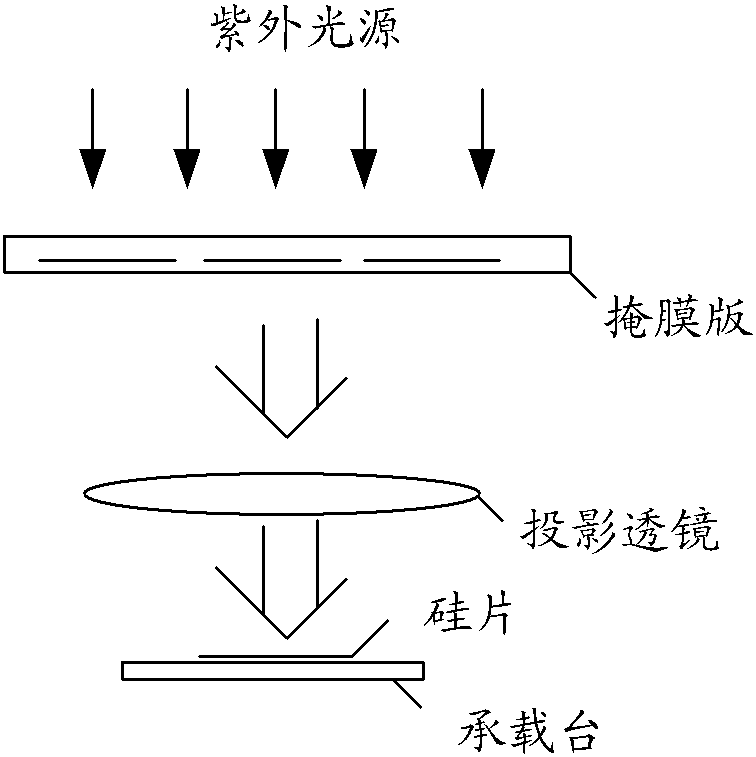

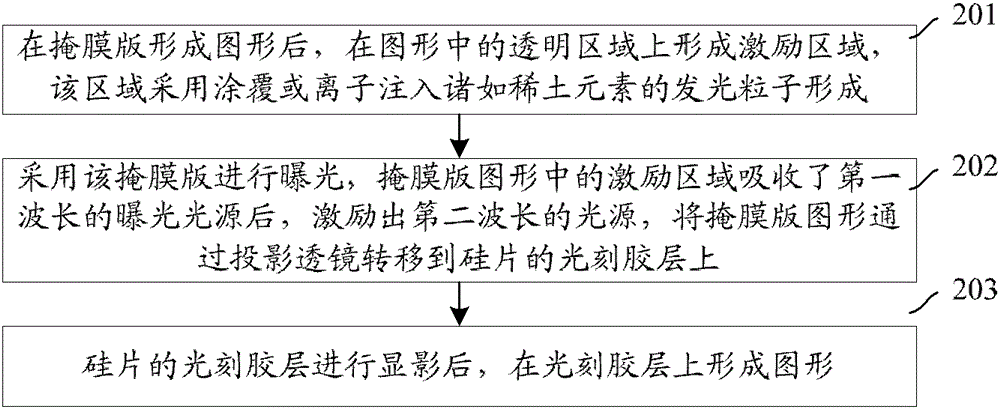

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0026] In the background technology, during the exposure process of photolithography, the reason for the diffraction phenomenon is that the pattern of the mask plate takes away the exposure energy, and makes the exposed light source diverge, and when it is transferred to the photoresist layer of the silicon wafer, the silicon The unexposed areas of the photoresist layer of the wafer are exposed. This situation becomes more pronounced as the feature size of semiconductor devices decreases, such as 200nm contact holes, and the transfer pattern on the silicon wafer caused by diffraction can make small contact holes and small lines difficult to be photolithographic.

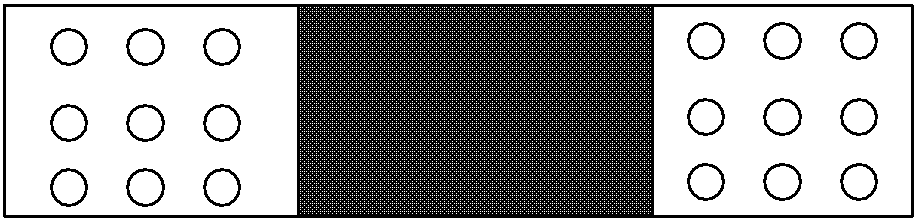

[0027] In order to overcome this problem, the present invention forms an excitation area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com