Multi-effect sludge drying equipment

A sludge drying and equipment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve high equipment and operating costs, pipe wall scaling, Low sludge calorific value and other issues, to achieve the effect of low equipment cost and operating cost, convenient water drainage, and low sludge moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

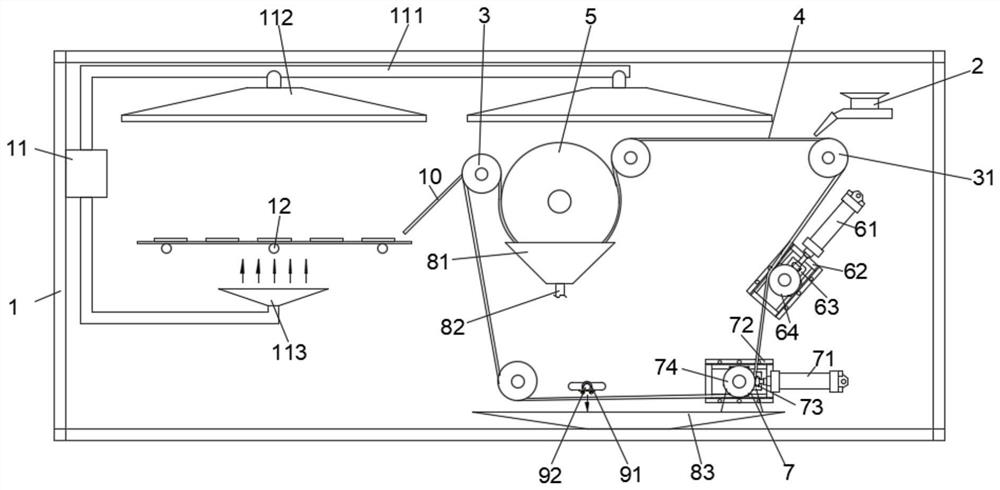

[0031] see figure 1 As shown, the present invention provides a technical solution for multi-effect sludge drying equipment: including a frame 1, specifically, an insulating device is provided in the frame 1, and the insulating device ensures that the electric energy between the cathode and the anode will not leak and short circuit, etc., to improve the safety of the equipment, a mud feeding device 2 is arranged on the upper right corner of the frame 1, and a dewatering mechanism is arranged below the mud feeding device 2. The concave shape is set, and a plurality of transmission rollers 3 are provided with a cathode metal chain 4, and are connected with the cathode metal chain 4. Specifically, a plurality of transmission rollers 3 are connected with a transmission device, and the transmission device can be a chain sprocket transmission , is driven by a motor, and the cathode metal chain 4 is provided with an anode roller 5. Specifically, the cathode metal chain 4 and the anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com