Support device for installing and disassembling cover plate

A technology for supporting devices and cover plates, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of time-consuming, large weight and volume of cover plates, laborious and other problems, and achieve the effects of convenient operation, reduced manufacturing cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

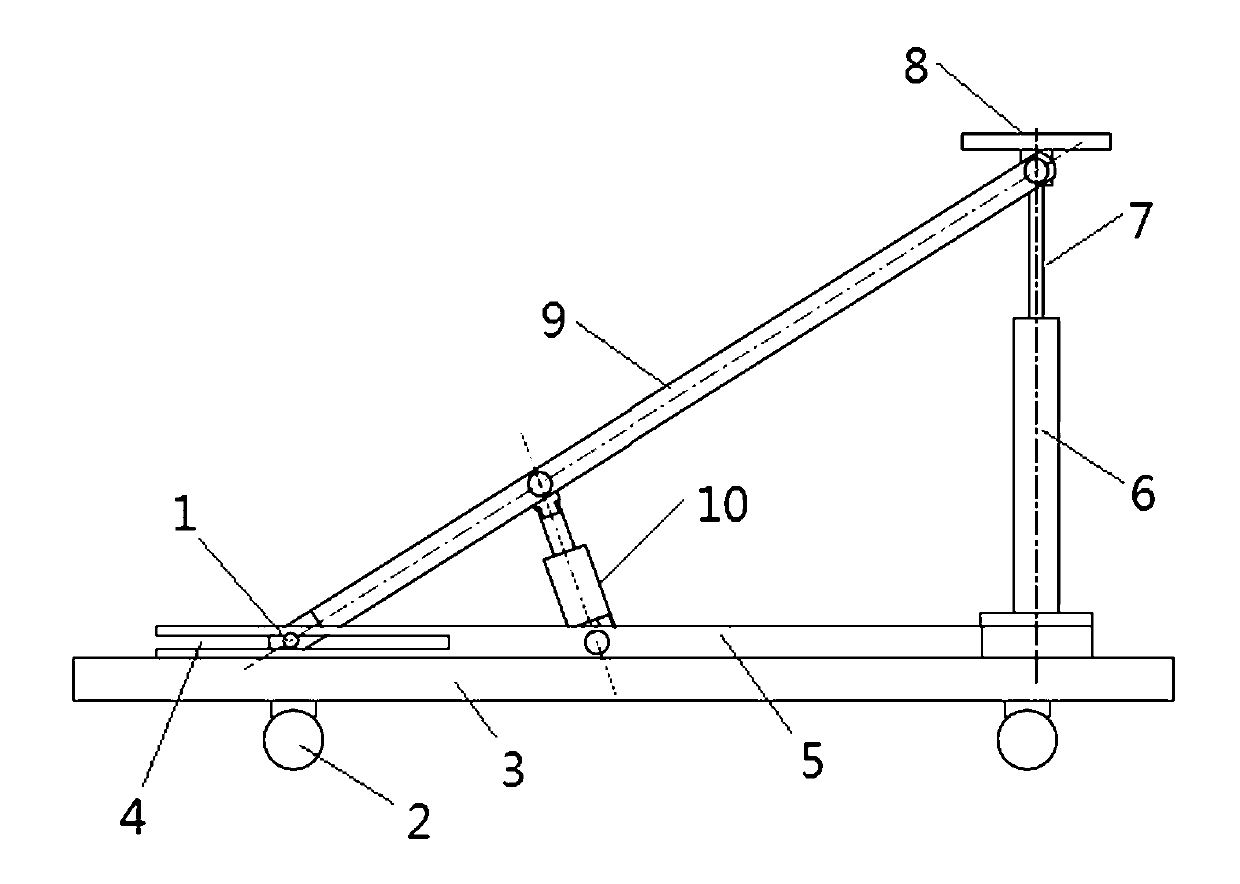

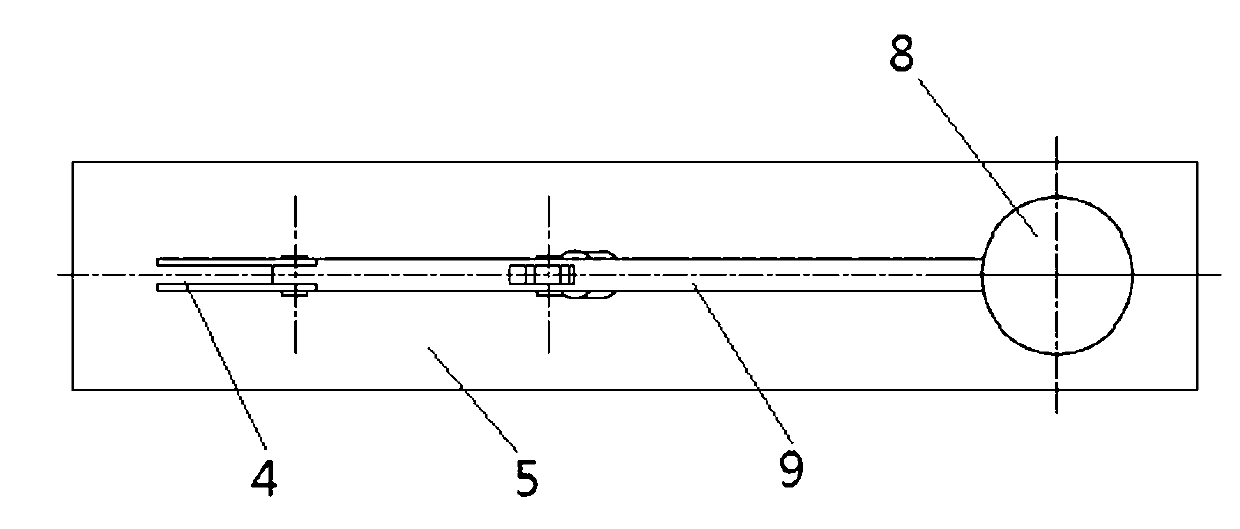

[0016] An example of a support device for cover installation and removal is Figure 1~2 Shown: comprise the vehicle frame that universal wheel 2 is housed at the bottom, vehicle frame comprises the chassis 3 that universal wheel is installed and the mounting plate 5 that is arranged on the chassis upper end, and lifting mechanism is set on the mounting plate 5. The lifting mechanism includes guide cylinders 6 arranged at intervals along the front and rear directions on the mounting plate 5 and jacks 10 with telescopic arms. The guide cylinder 6 has an inner hole extending up and down in the guiding direction, and a guide rod is inserted in the inner hole for guiding and sliding. The barrel constitutes the vertical guide structure. The top end of the guide rod is fixedly equipped with a support plate 8 for placing the corresponding cover plate through a detachable connection structure. The lifting mechanism also includes a transmission diagonal rod 9. The lower side of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com