Manual winding device for coal conveying belt

A belt and coal conveying technology, which is applied in the field of manual coiling device for coal conveying belt, can solve problems such as difficulty in manual coiling of coal conveying belt, and achieve the effects of reducing manpower input, labor intensity and safety hazard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

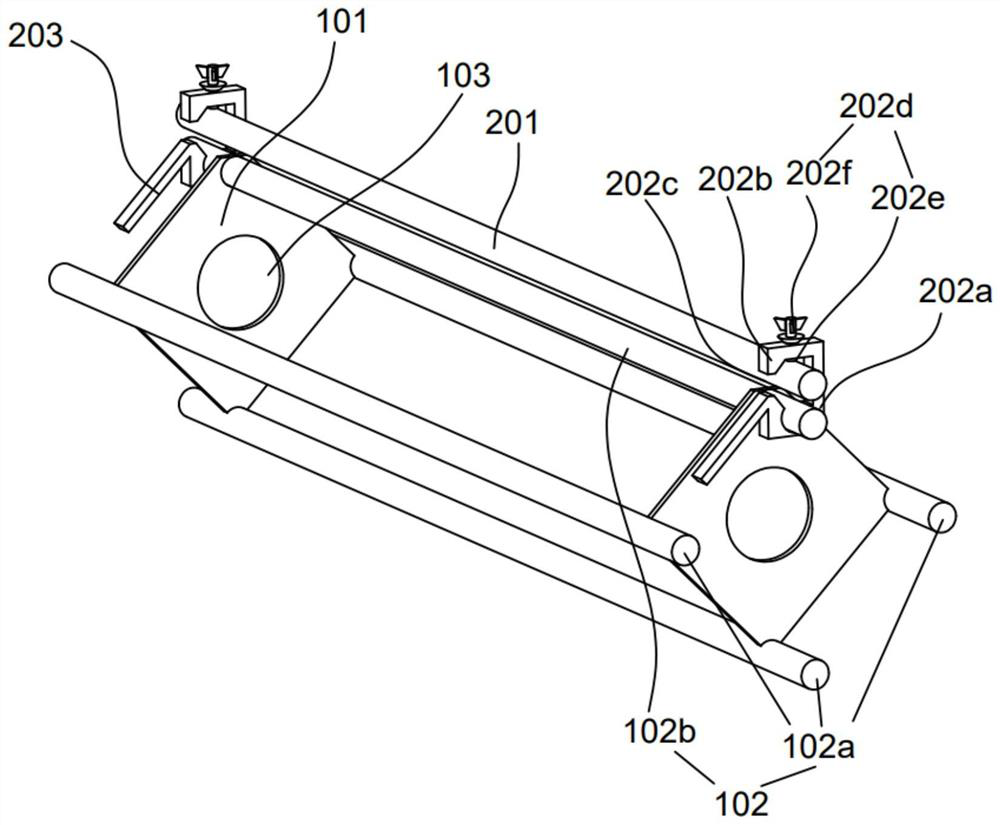

[0029] This embodiment provides a coal conveyor belt manual winding device, such as Figure 1-2 shown, including,

[0030] The fixed module 100 and the clamping module 200, the fixed module 100 is a bracket formed by welding and fixing in the device, and the shape will not change. The clamping module 200 is used to cooperate with the fixed module 100 to carry out the coal conveyor belt that needs to be rewound. The end is fixed, and then through the overall rotation of the device, the coal conveyor belt is wound on the device.

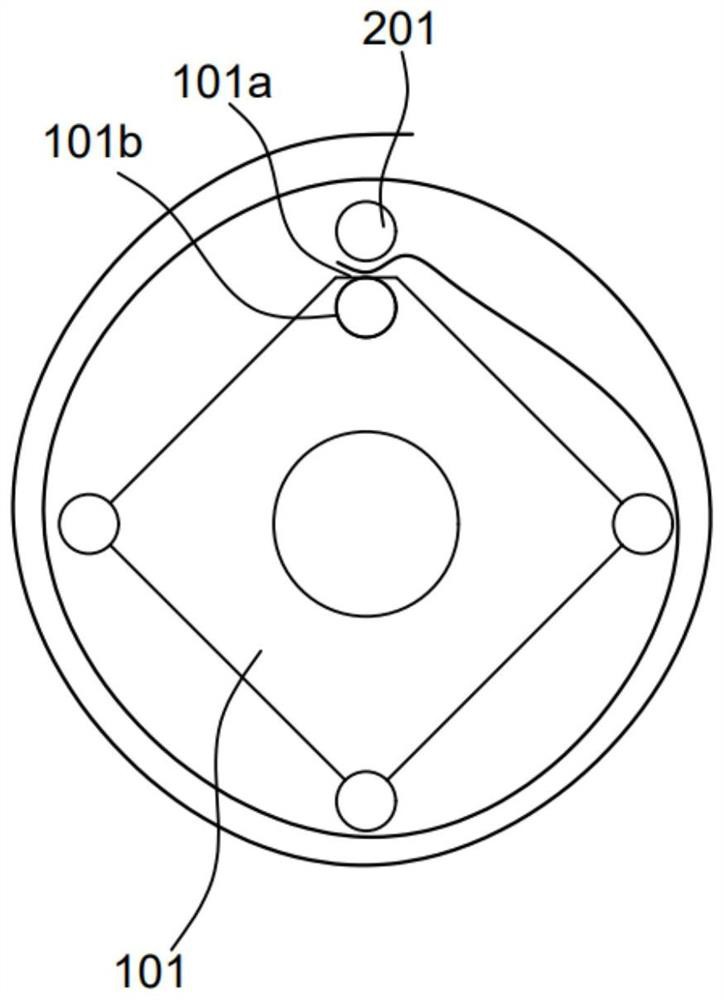

[0031] Specifically, the fixed module 100 includes two baffle plates 101 arranged in parallel, the baffle plates 101 are arranged in a square shape, a fixed link 102 is connected to the right angle position of the baffle plate 101, and a rotating shaft hole 103 is opened in the center of the baffle plate;

[0032] The clamping module 200 includes a movable link 201 cooperating with one of the fixed links 102 on the baffle, and the movable link 201 is ...

Embodiment 2

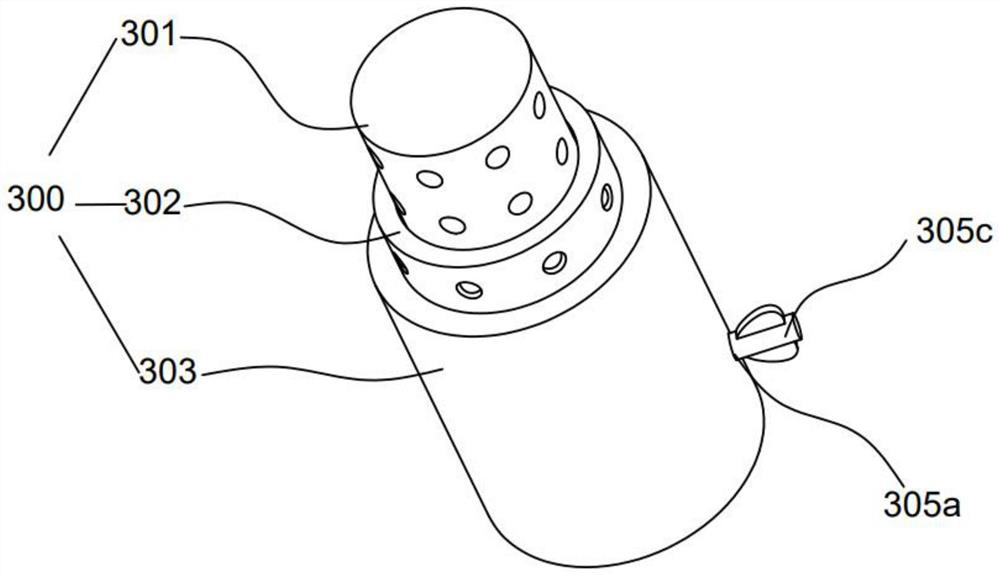

[0039] This embodiment is different from the previous embodiment in that, as Figure 3-7 shown, where

[0040] The first connecting rod 102a, the second connecting rod 102b and the movable connecting rod 201 are all arranged as length-adjustable connecting rods 300, which all include an outer sleeve 301, an intermediate pipe 302 and an inner sleeve 303, and the outer sleeve 301 and the intermediate pipe 302 are axially connected to each other. The inner sleeve 303 and the intermediate tube 302 are axially slidingly connected, the inner side wall of the outer sleeve 301 is provided with a first groove 301a, and the outer side wall of the inner sleeve 303 is provided with a second groove 303a , the intermediate pipe 302 is radially opened with a through hole 302a, and a moving block 304 is arranged in the through hole 302a.

[0041] At least two of the first groove 301a and the second groove 303a are evenly arranged in the circumferential direction, and a plurality of them are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com