Anti-deviation coal conveying belt winding device

A technology of anti-tracking and coal conveying, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of manual rolling up of coal conveying belts, etc., to reduce manpower input, reduce labor intensity, and reduce safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

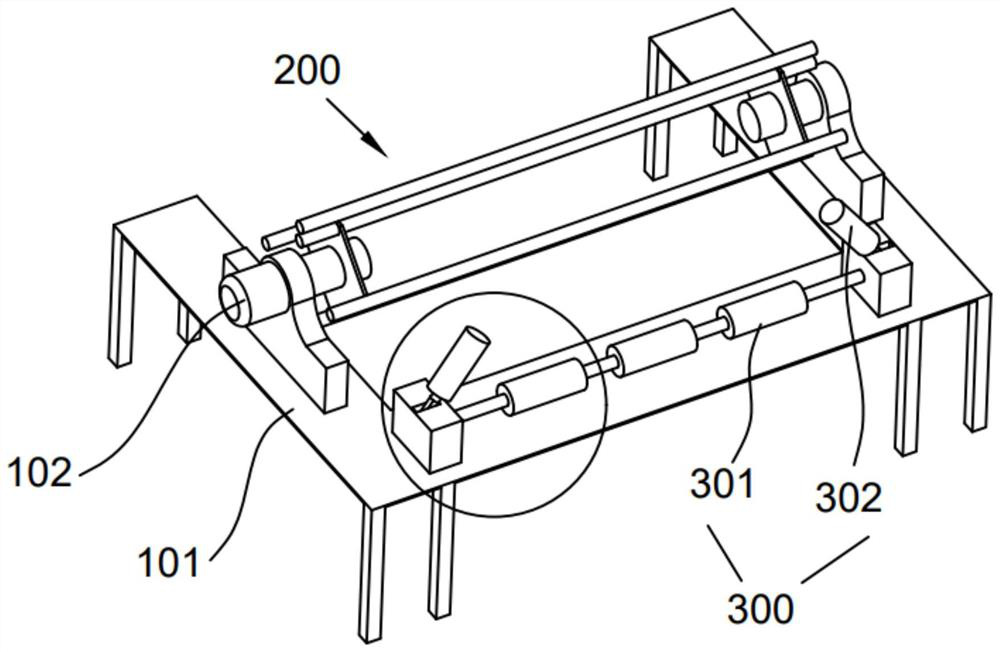

[0025] This embodiment provides an anti-deviation coal conveying belt take-up device, such as Figure 1-2 shown, including,

[0026] Bracket 101, the take-up cylinder 200 arranged on the support 101 and the roller assembly 300 arranged on the support 101, the take-up cylinder 200 is used to fix the end of the belt, and then the belt is rolled up by rotation, the idler The assembly 300 can prevent the belt from running off during electric rotation, and can automatically adjust the belt.

[0027] Specifically, the bracket 101 is mainly used as a support, and its shape is not specified. It can mainly satisfy the need to support the rotation of the take-up cylinder 200 without affecting the collection of the rolled-up belt, and then the idler assembly 300 can also be installed on it. That's it. The winding cylinder 200 is rotationally connected with the bracket 101, and a rotating shaft is arranged on the bracket 101. The rotating shaft can be connected with the winding cylinder...

Embodiment 2

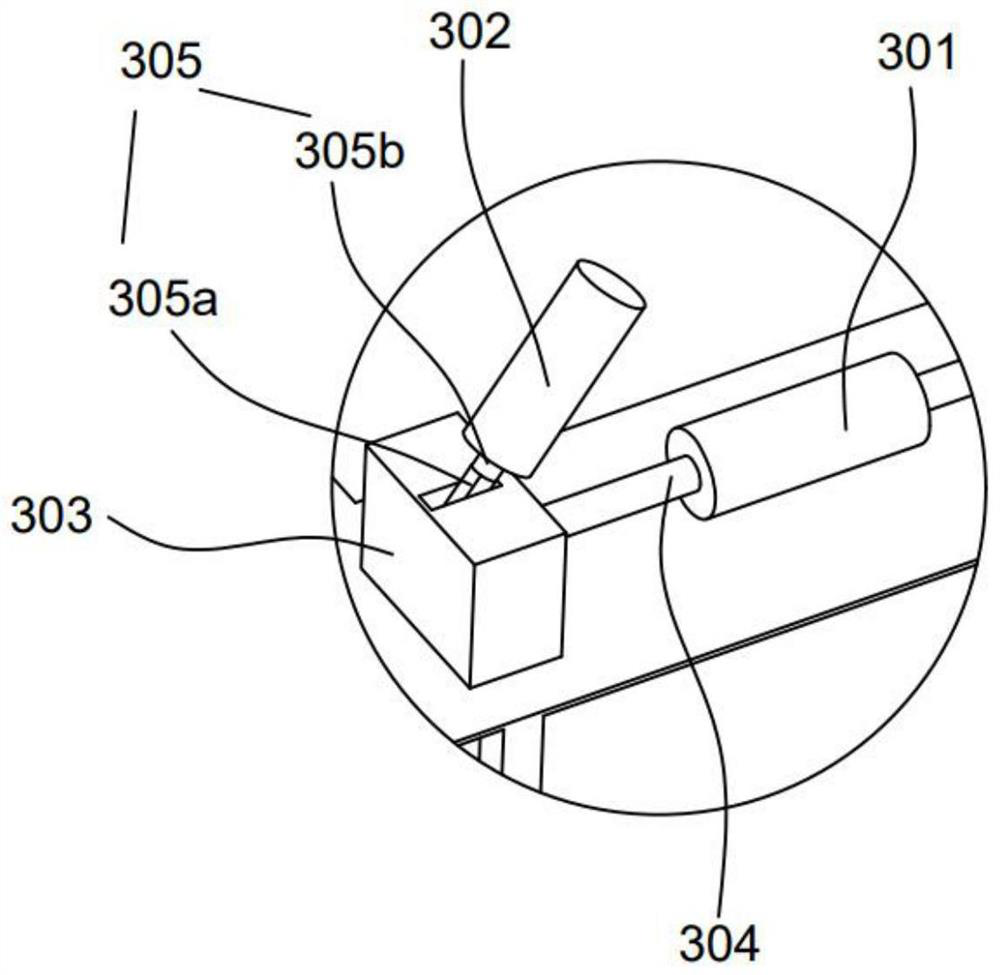

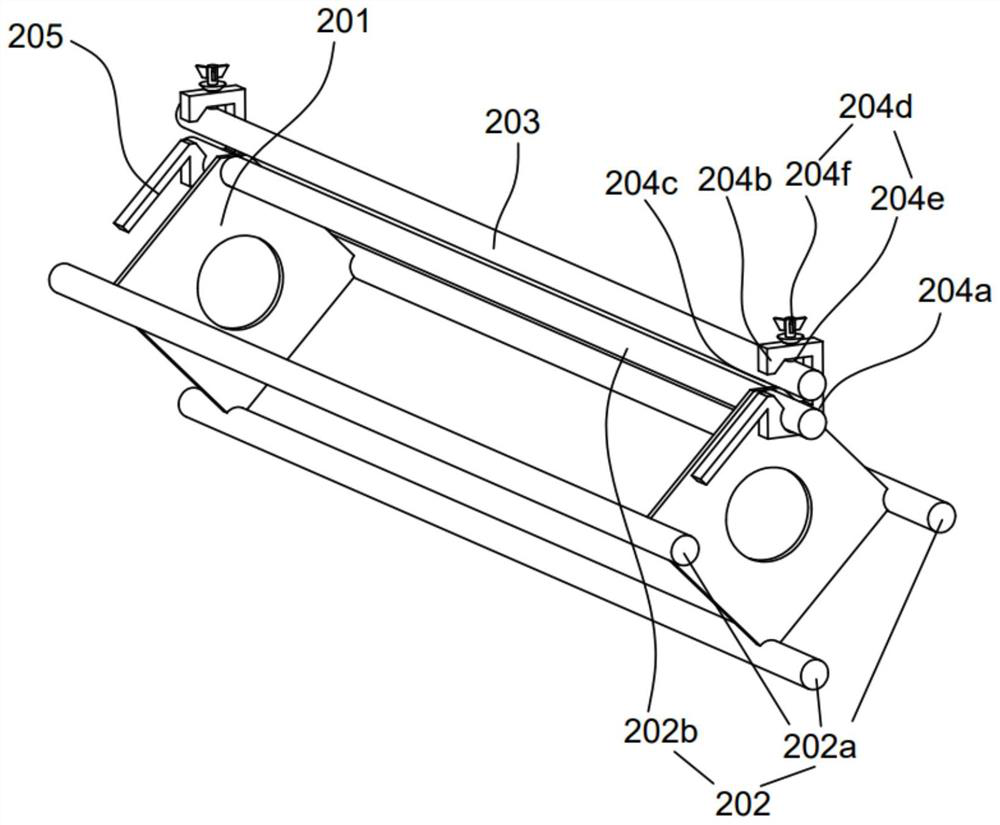

[0032] This embodiment is different from the previous embodiment in that, as Figure 3-4 As shown, among them,

[0033] The take-up cylinder 200 includes two square baffle plates 201 arranged in parallel, four fixed links 202 are arranged at the four corners of the baffle plate 201, and a movable link is arranged on one of the fixed links 202 203 is connected with it, and a link lock 204 is arranged between the movable link 203 and the fixed link 202 for fixing and dismounting. The fixed connecting rod 202 includes three first connecting rods 202a and one second connecting rod 202b, wherein the first connecting rods 202a are respectively connected to three right angles of the baffle plate 201, and the remaining one right angle of the baffle plate 201 is provided with a notch. A circular hole 201b is opened inside the corner 201a and the notch 201a, and the circular hole 201b is tangent to the edge of the notch 201a, and the second connecting rod 202b passes through the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com