Method for calculating working resistance of hydraulic support and method for selecting hydraulic support

A technology of hydraulic support and working resistance, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as low top coal recovery rate, short support life, and increased unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. It is only intended to describe the specific embodiments of the present invention in detail, and does not limit the present invention, and the protection scope of the present invention is subject to the claims.

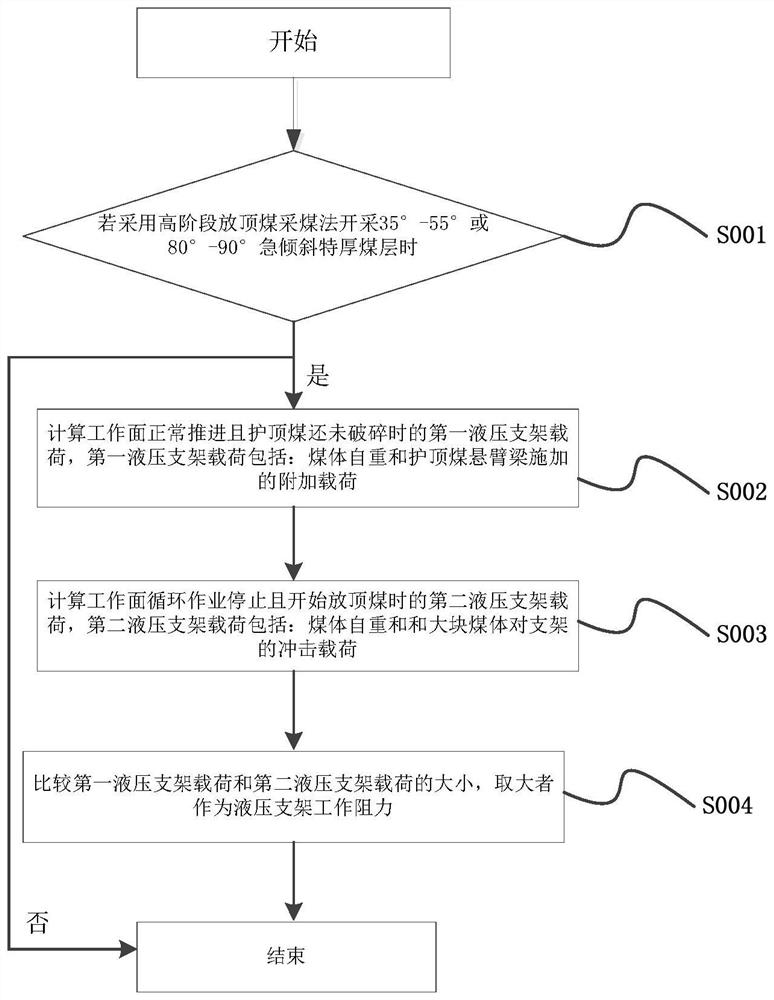

[0045] refer to figure 1 , the present invention proposes a method for calculating the working resistance of a hydraulic support, comprising:

[0046] Step S001, if the high-stage top coal mining method is used to mine 35°-55° or 80°-90° steeply inclined extra-thick coal seams, the processing is as follows:

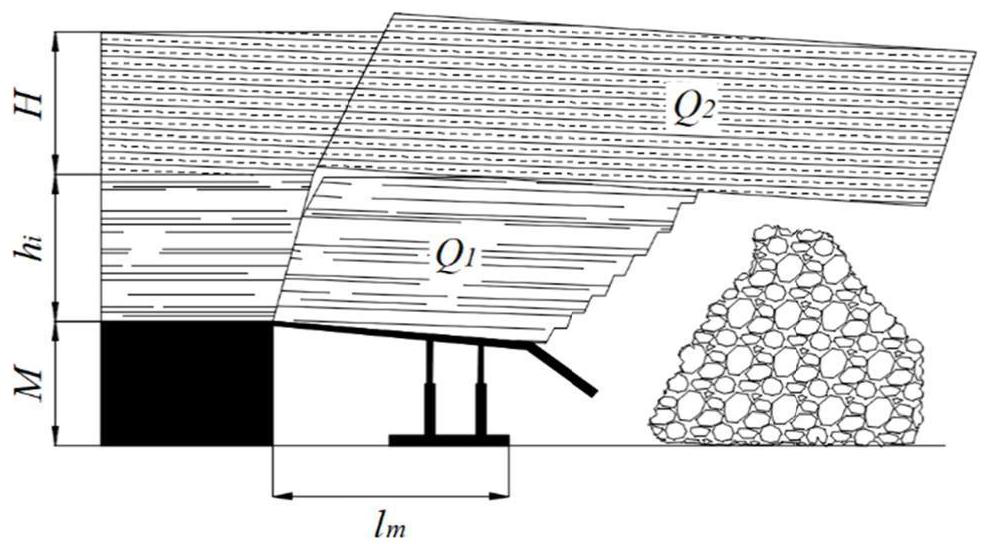

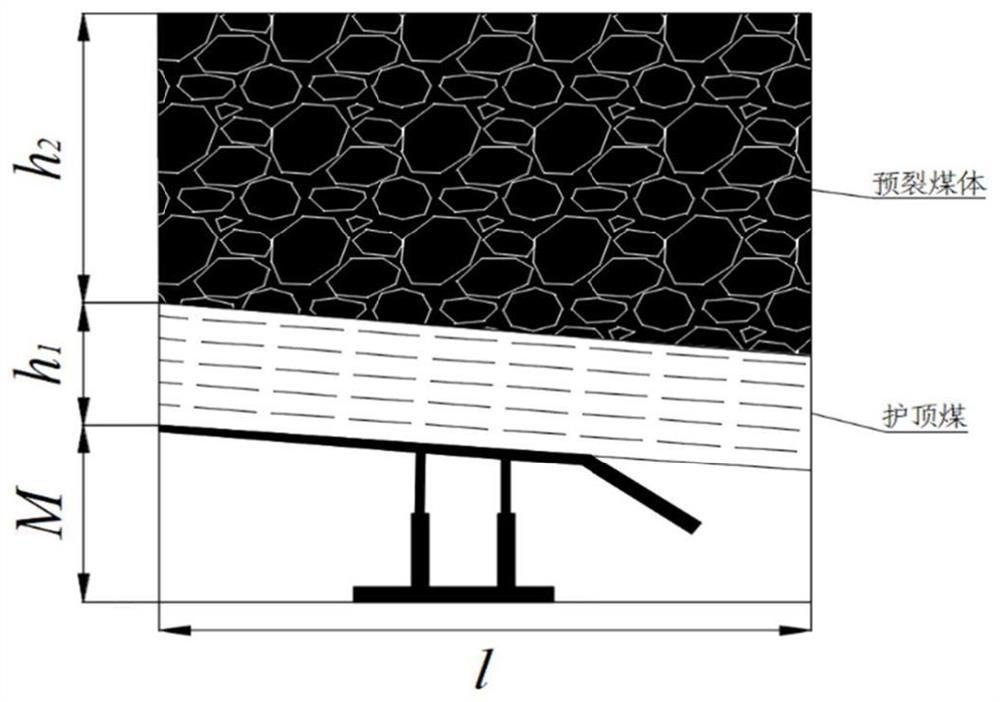

[0047] Step S002, calculating the first hydraulic support load when the working face is normally advanced and the top protection coal is not broken, the first hydraulic support load includes: the self-weight of the coal body and the additional load imposed by the top protection coal cantilever beam;

[0048] Step S003, calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com