Brushless motor of range hood

A technology of brushless motors and range hoods, applied in electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as low safety performance, low energy consumption level, and inconvenient speed regulation, and achieve The effects of high safety performance, cost reduction, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

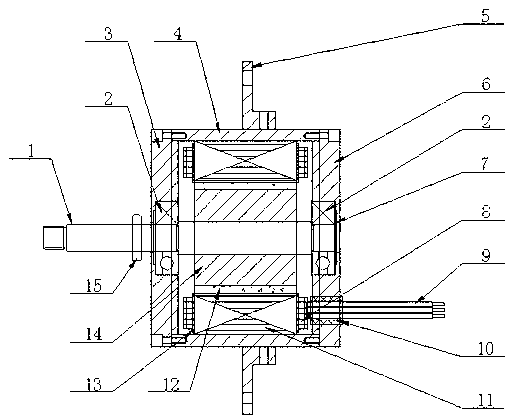

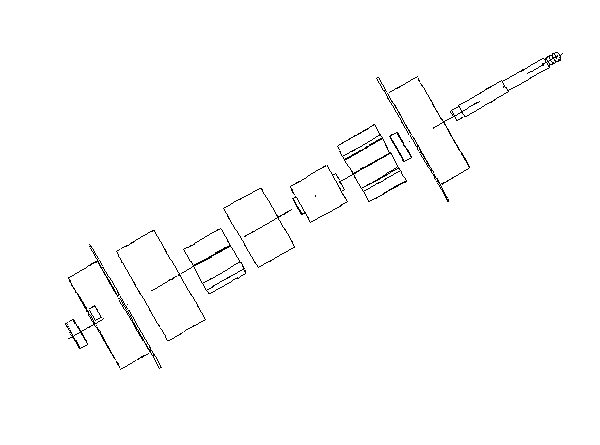

[0012] see Figure 1-Figure 2 , the specific embodiment adopts the following technical scheme: it includes motor shaft 1, ball bearing 2, front end cover 3, casing 4, flange plate 5, rear end cover 6, corrugated meson 7, enameled wire 8, three-phase power line 9 , protective coil 10, stator core 11, magnetic steel 12, shaft coupling 14, positioning pin 15, ball bearings 2 are installed in the center holes of the front end cover 3 and the rear end cover 6, and the motor shaft 1 is connected in the two ball bearings 2 , the front end cover 3 and the rear end cover 6 are respectively installed on the front and rear ends of the casing 4, the flange 5 is sleeved on the outside of the casing 4, the corrugated meson 7 is set on one side of the ball bearing 2, and the shaft coupling 14 is set on the machine The inside of the shell 4 is sleeved on the motor shaft 1, the outer side of the shaft coupling 14 is provided with a magnetic steel 12, the outer side of the magnetic steel 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com