Line filter, AC power supply and method for manufacturing the line filter

A technology of AC power supply and AC power, applied in AC network to reduce harmonics/ripples, conversion equipment with intermediate conversion to AC, electrical components, etc., can solve the problem of increased manufacturing costs, increased drilling work, and linear filters Larger area and other issues, to achieve the effect of process reduction, PCB area reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present disclosure will be described in more detail with reference to the accompanying drawings.

[0042] In the following description, only the suffixes "module" and "unit" are added for convenience of description in the specification, and the suffixes "module" and "unit" may be used compatible with each other.

[0043] In addition, although the embodiments will be described in detail below with reference to the drawings and the contents indicated in the drawings, the embodiments are not limited thereto.

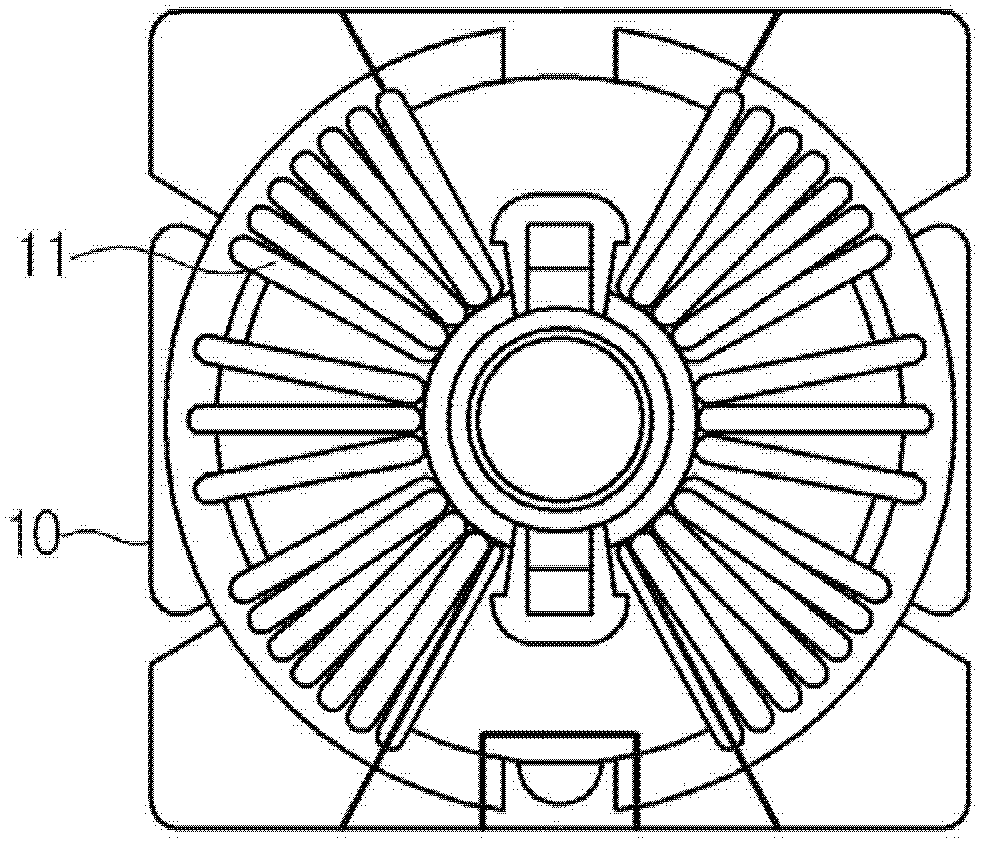

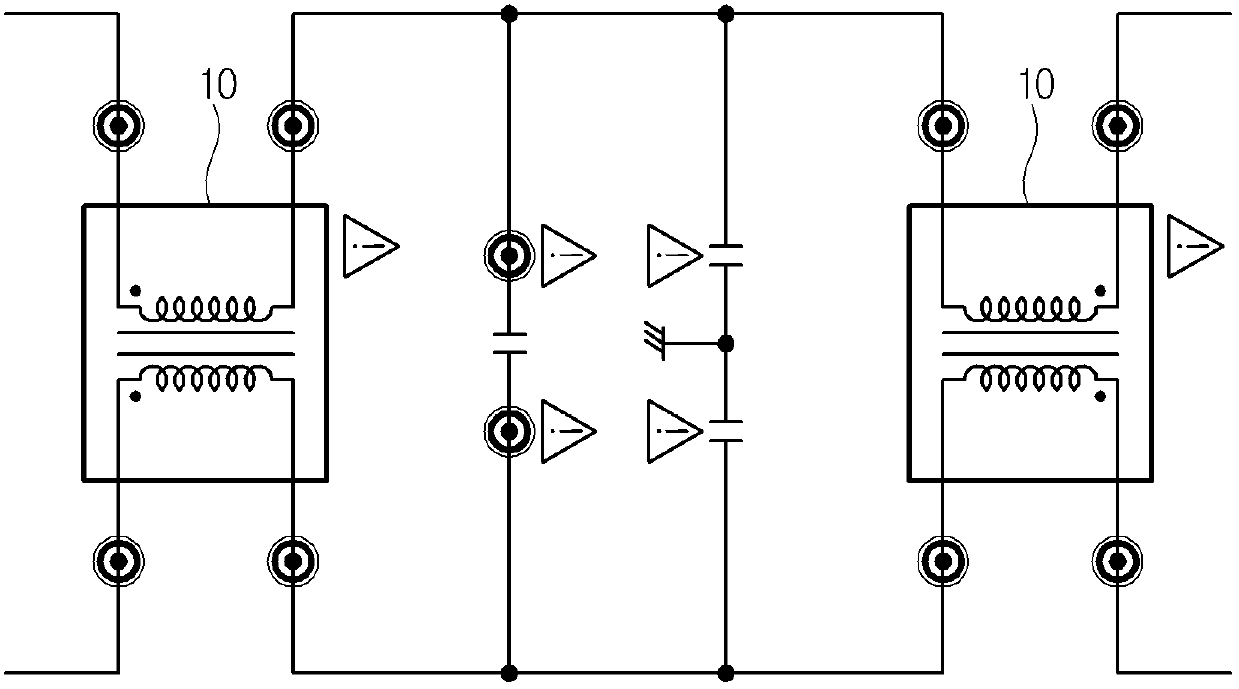

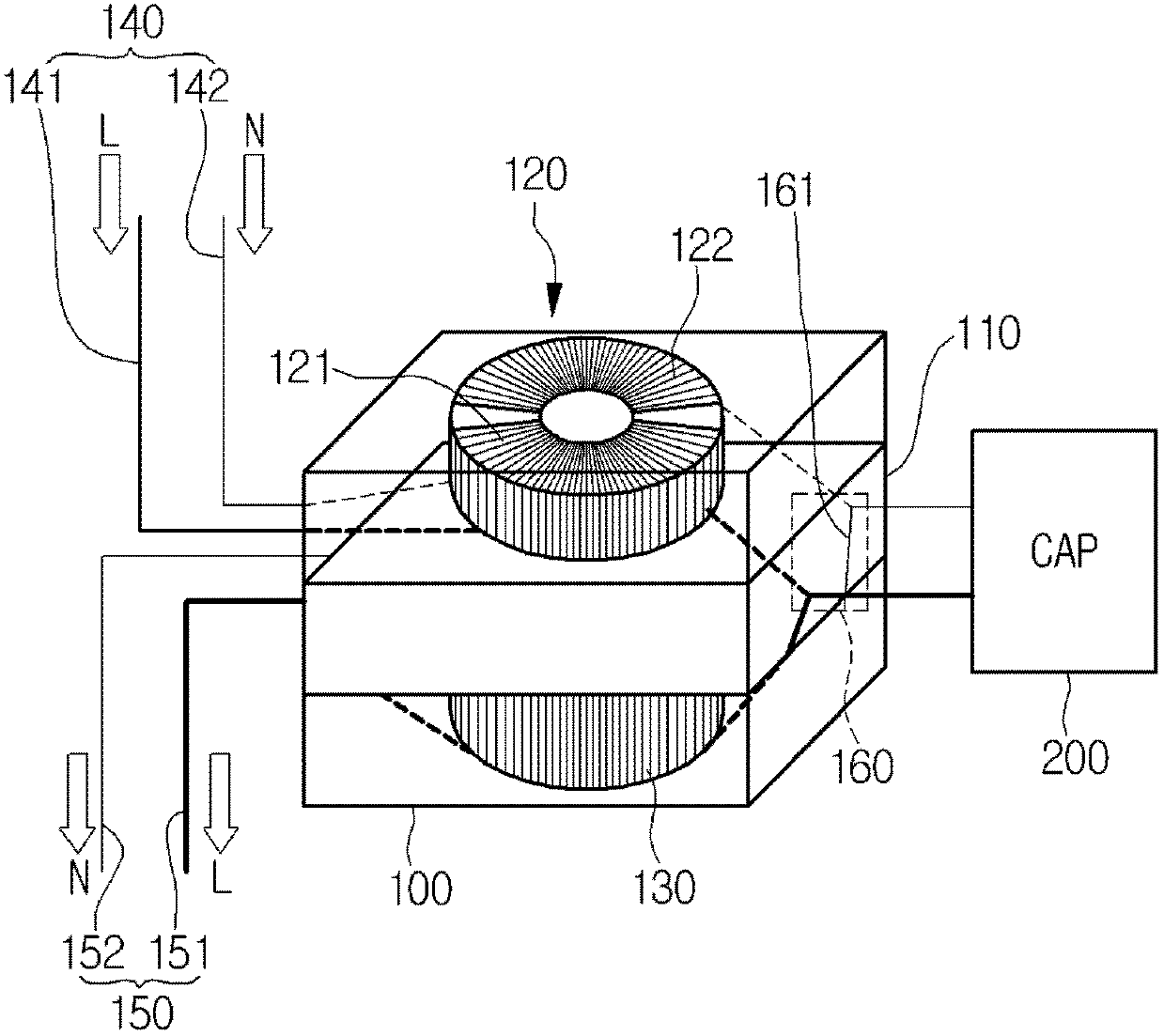

[0044] image 3 is a view showing the structure of the two-stage linear filter 100 according to one embodiment.

[0045] Below, will refer to image 3 The two-stage linear filter 100 according to one embodiment is described in detail.

[0046] Such as image 3 As shown, the two-stage linear filter 100 according to this embodiment includes a bobbin 110 , a first coil 120 , a second coil 130 , an input line 140 , an output line 150 and a connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com