Brushless motor for washing machine and drum-type washing machine provided with same

A drum-type washing machine and washing machine technology, which is applied to other washing machines, household appliances, applications, etc., can solve the problems that water cannot reach the motor 60, cannot sufficiently suppress rusting, and have poor electrical leakage and tracking, and achieve the effect of high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

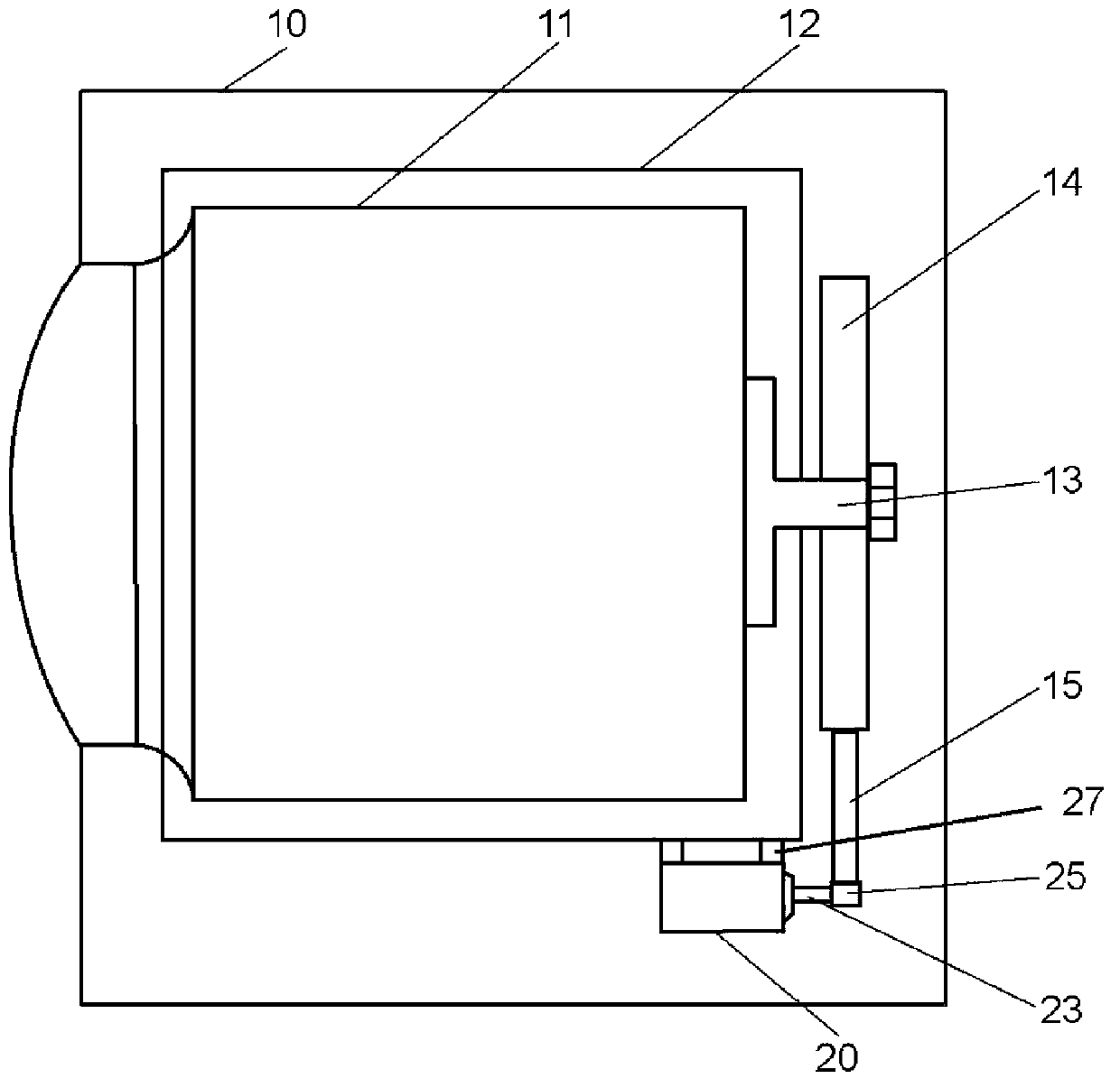

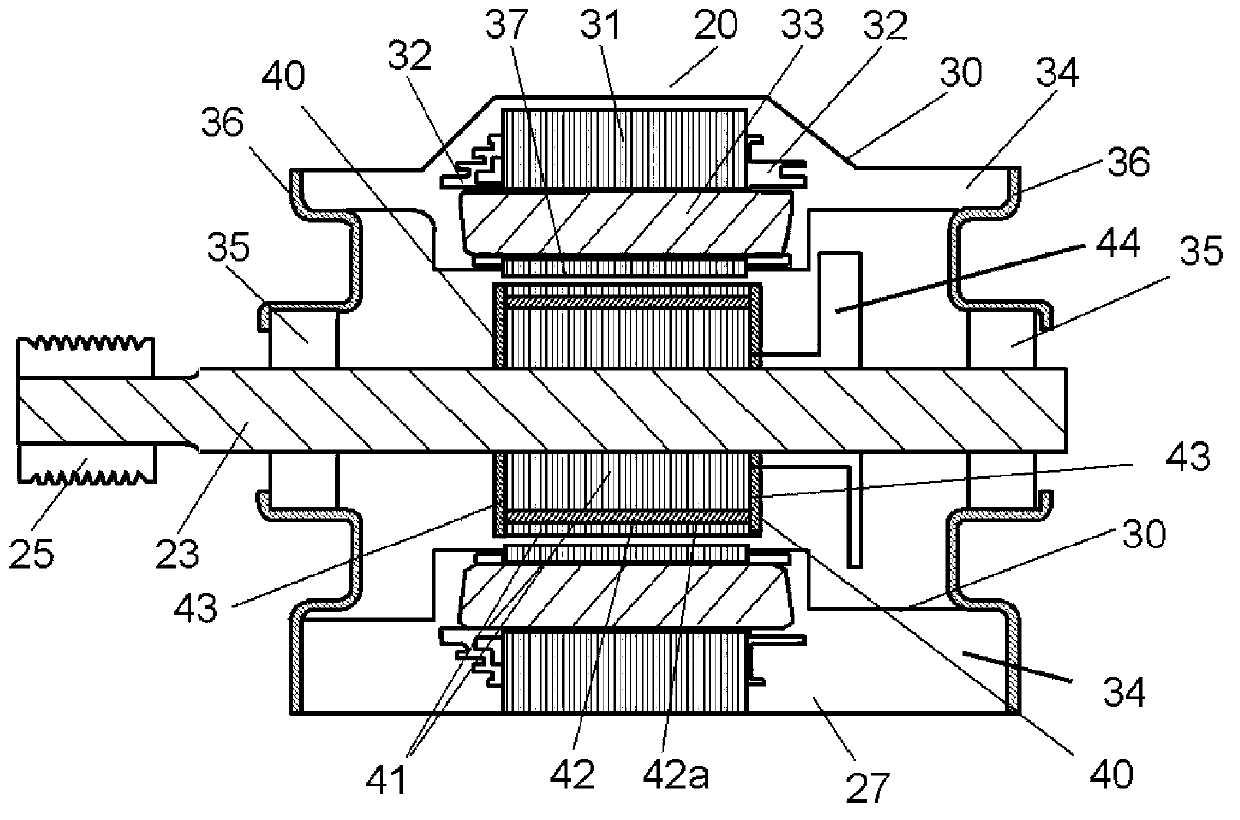

[0030] figure 1 It is a diagram showing a schematic configuration of a front-loading washing machine equipped with a brushless motor for a washing machine according to Embodiment 1 of the present invention. Such as figure 1 As shown, the drum type washing machine 10 wraps the rotating drum 11, and the drum type washing machine 10 supports the rotating drum 11 so that the rotating drum 11 can rotate freely. The water tank 12 elastically supported in the main body of the washing machine. In addition, a pulley 14 that transmits power to the rotary drum 11 via a drum rotating shaft 13 and a motor 20 that transmits power to the pulley 14 via a belt 15 are provided on the back surface of the water tank 12 . In the present embodiment, a brushless motor is employed as the motor 20 in order to achieve high efficiency and the like. Additionally, if figure 1 As shown, in this embodiment, the motor 20 is fixed below the water tank 12 by means of the mounting portion 27 .

[0031] ...

Embodiment approach 2

[0040] Figure 5 It is a figure which shows the structure of the brushless motor for washing machines concerning Embodiment 2 of this invention. Figure 5 The illustrated brushless motor for a washing machine is the same as the brushless motor for a washing machine in Embodiment 1 described above, and also resembles a brushless motor for a washing machine. figure 1 That is used in a front-loading washing machine. In addition, in Figure 5 In , the same reference numerals as in Embodiment 1 are assigned to the same constituent elements as in Embodiment 1. FIG.

[0041] Such as Figure 5 As shown, motor 120 as a brushless motor for washing machine according to this embodiment includes stator 130 fixed to water tank 12 of front-loading washing machine 10 , and rotor 140 held by stator 130 and rotatable relative to stator 130 .

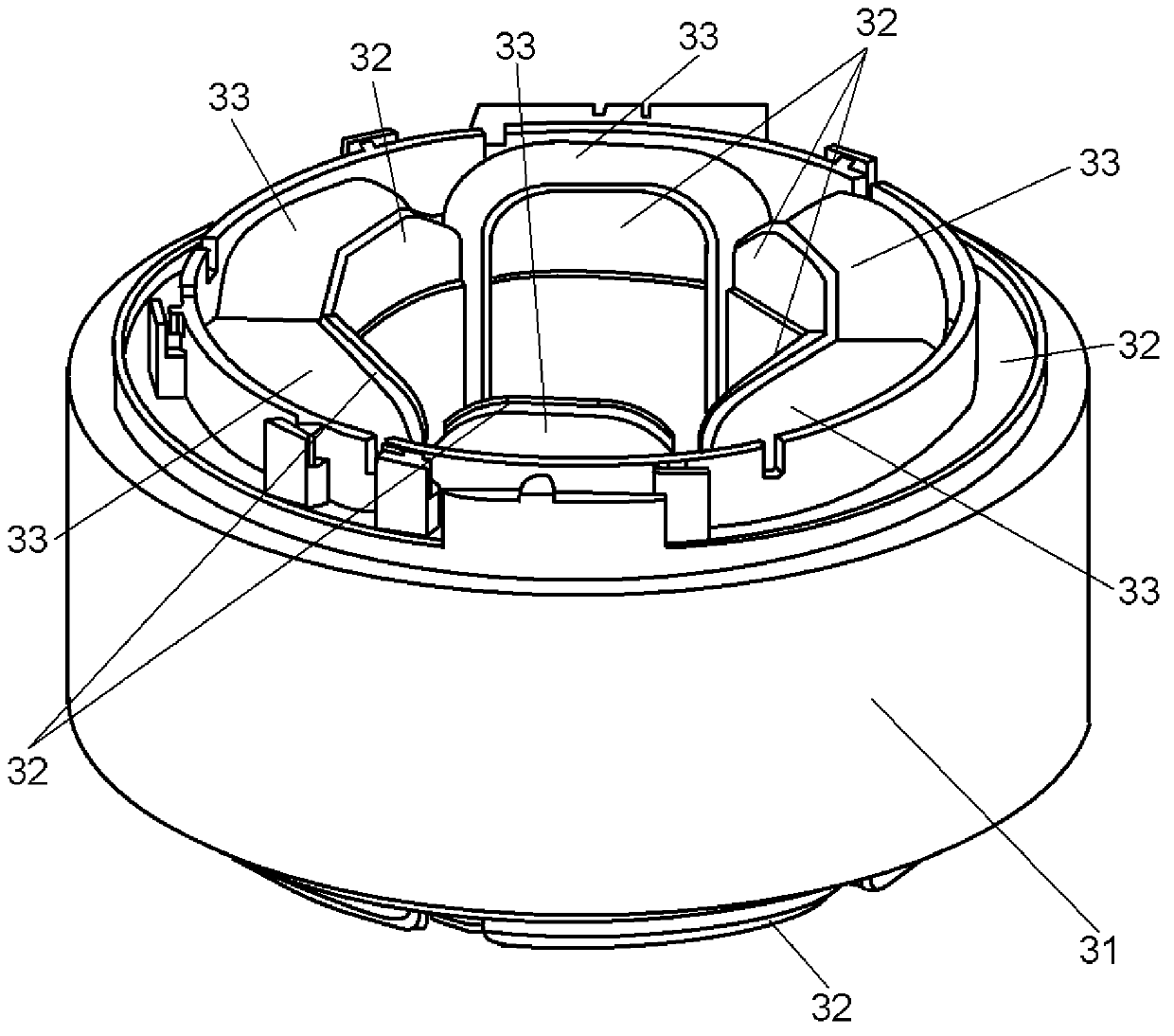

[0042] The stator 130 includes a stator core 31 , a winding 33 , a stator frame 38 and a mounting part 27 . The structures of the stator core 31, t...

Embodiment approach 3

[0057] Figure 10 It is a figure which shows the structure of the brushless motor for washing machines concerning Embodiment 3 of this invention. Figure 10 The shown brushless motor for washing machine is the same as the brushless motor for washing machine in Embodiment 1 and Embodiment 2 described above, and also resembles figure 1 That is used in a front-loading washing machine. In addition, in Figure 10 Herein, the same reference numerals as those in Embodiment 1 and Embodiment 2 are attached to the same constituent elements as in Embodiment 1 and Embodiment 2. FIG.

[0058] Such as Figure 10As shown, a motor 220 as a brushless motor for a washing machine according to this embodiment includes a stator 30 fixed to the water tank 12 of the front-loading type washing machine 10, and a rotor 140 held by the stator 30 to freely rotate.

[0059] The stator 30 is the same as that of Embodiment 1, and includes a stator core 31 , a winding 33 , a stator molded portion 34 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com