Valve for controlling fluids

A technology for controlling fluid and valve seat, applied in the direction of lifting valve, valve device, brake, etc., can solve the problems of small construction space, increase of flow resistance, decrease of valve flow rate, etc., and achieve the effect of improving flow and reducing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

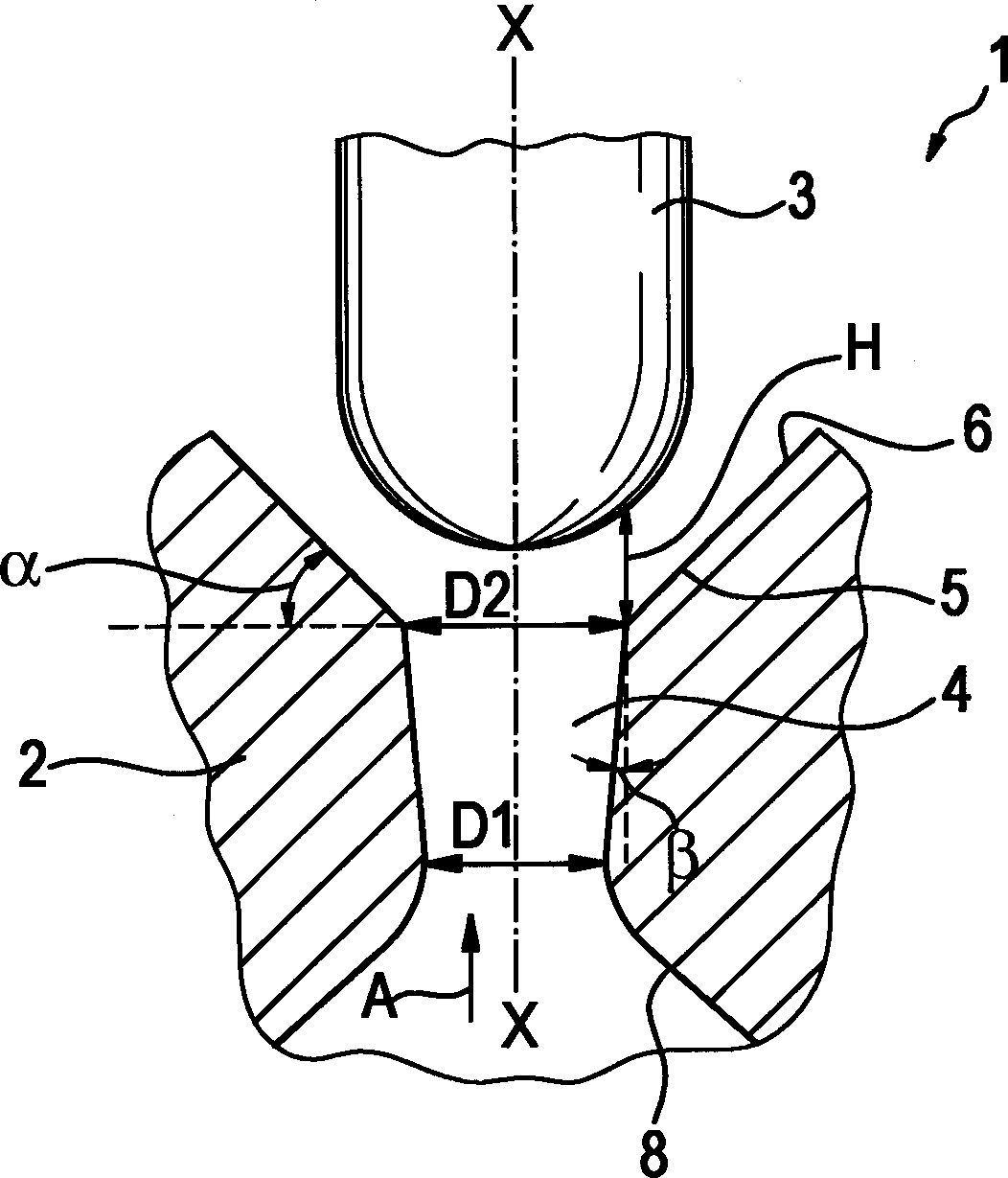

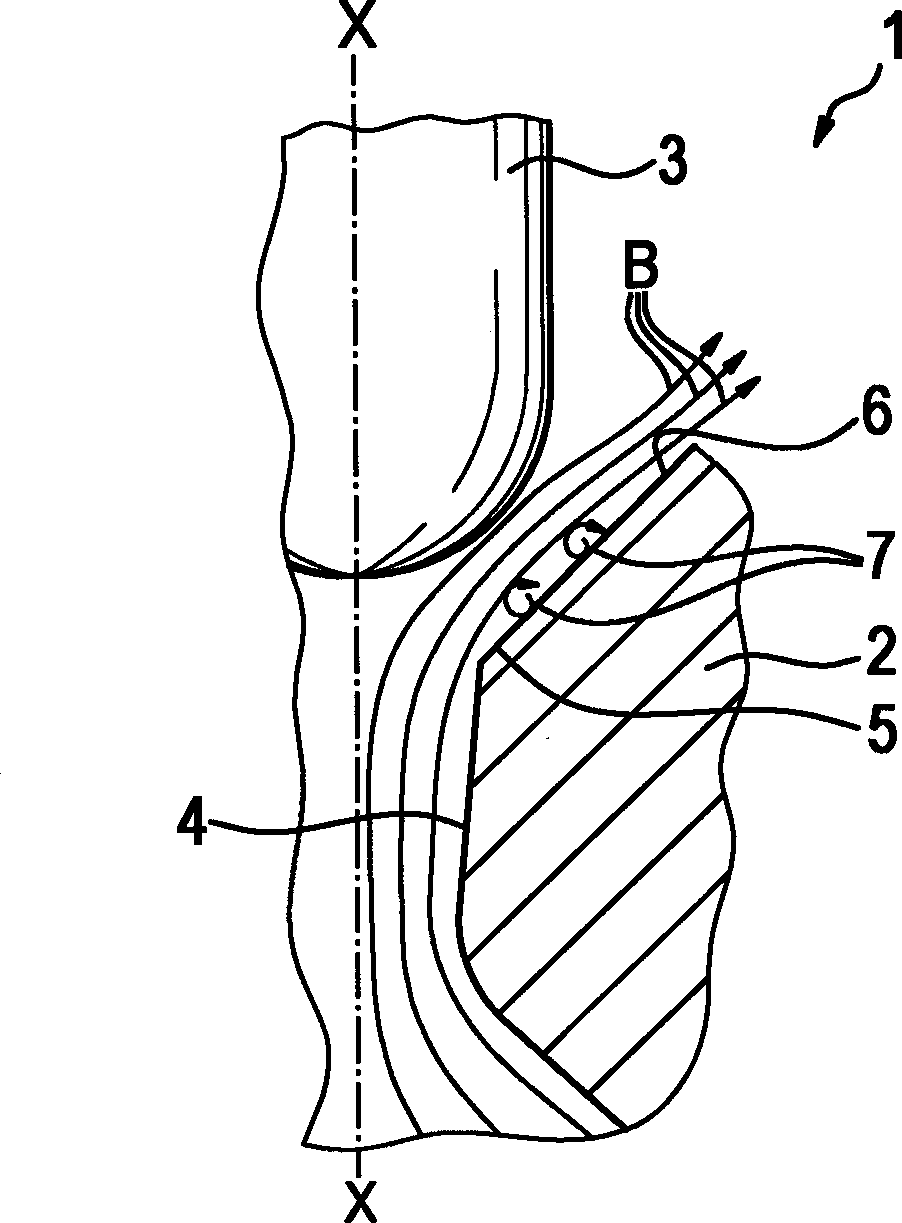

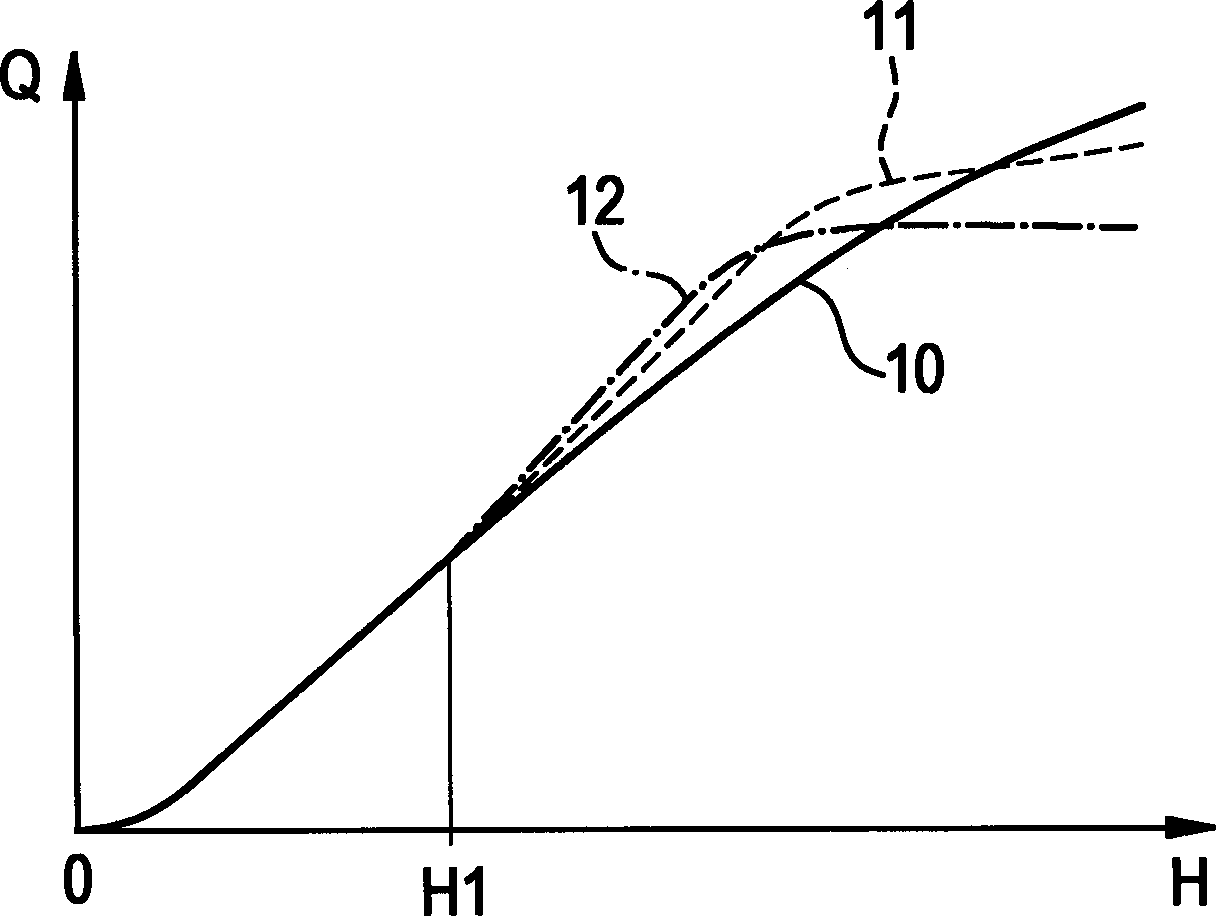

[0017] The following will refer to Figures 1 to 3 A valve 1 for controlling fluid is specifically described. The valve 1 is used as a distribution valve in a brake safety system of a motor vehicle.

[0018] like figure 1 As shown, the valve 1 comprises a valve element 2 with a through hole 4 and a valve seat 5 formed on the valve element 2 . The valve seat 5 is formed on a first conical region 6 of the valve element. The closing member 3 is semicircular and seals on the valve seat 5 .

[0019] like figure 1 As shown, the through-opening 4 has a shape that widens in the flow direction A of the valve 1 . In this exemplary embodiment, the through-opening 4 widens conically. At the same time, the angle β between the through hole and the parallel line of the central axis X-X is 7.5°. Here, the minimum diameter D1 of the through hole and the maximum diameter D2 of the through hole are selected such that the ratio of the minimum diameter D1 to the maximum diameter D2 is 0.78....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com