Microstructure surface plastic forming combination roller

A plastic forming and microstructure technology, which is applied in the field of mechanical engineering, can solve problems such as low efficiency and reduced precision of microstructure forming, and achieve the effects of saving processing costs, improving processing accuracy, and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

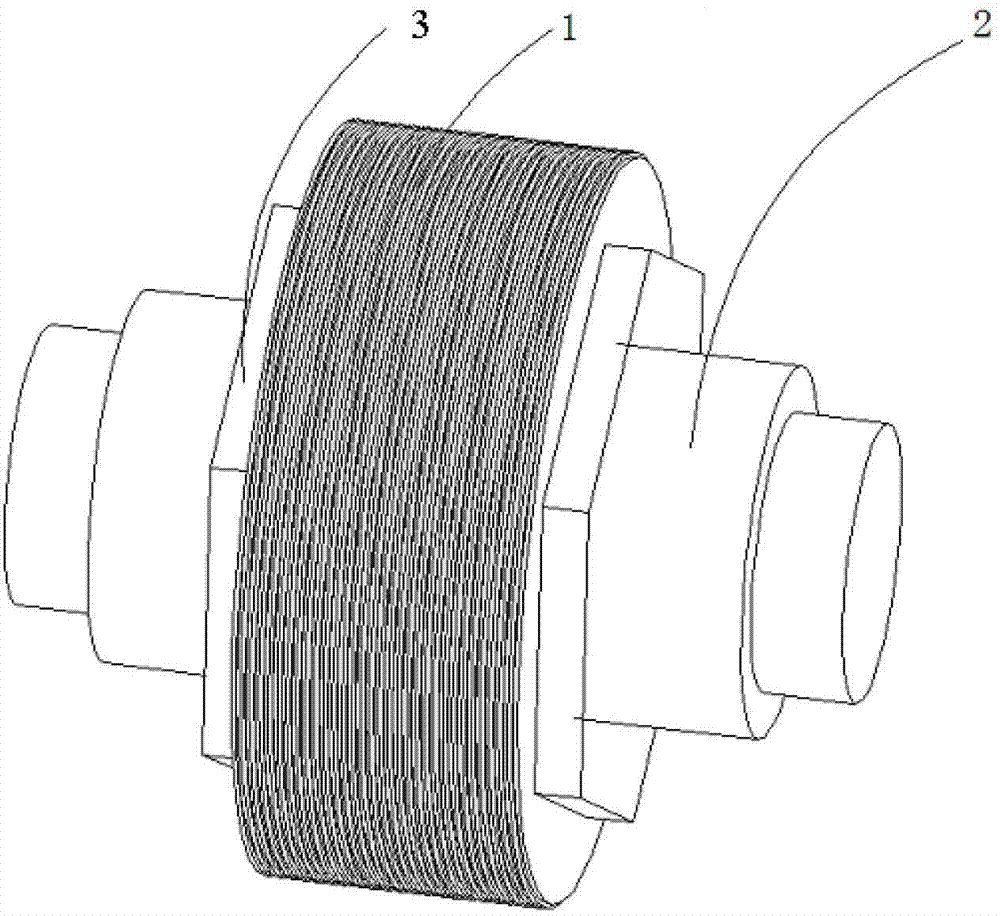

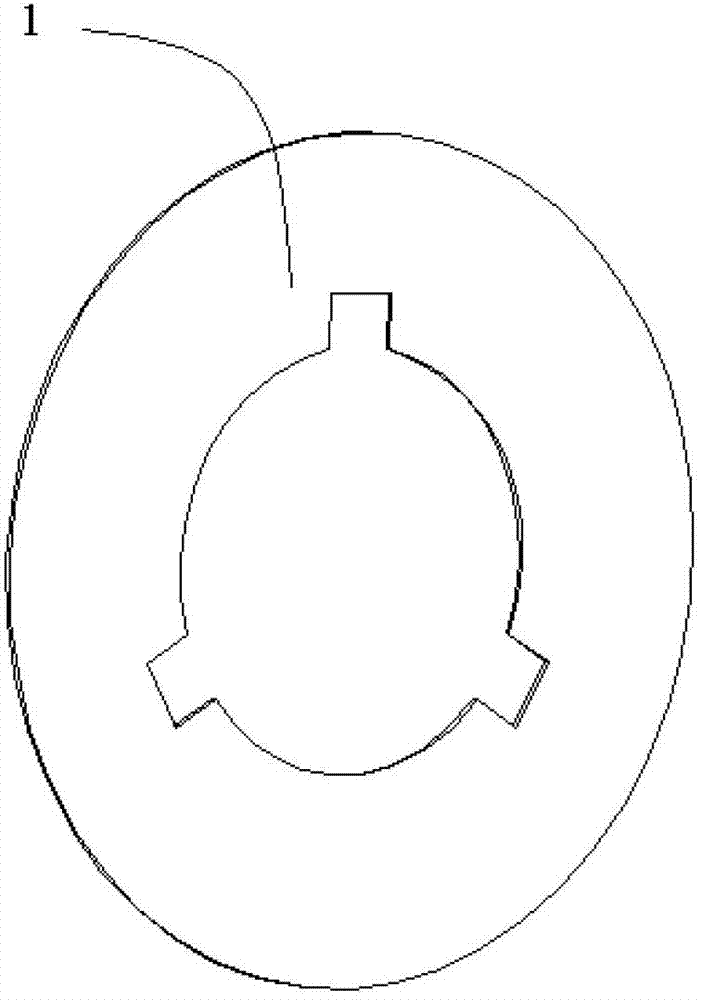

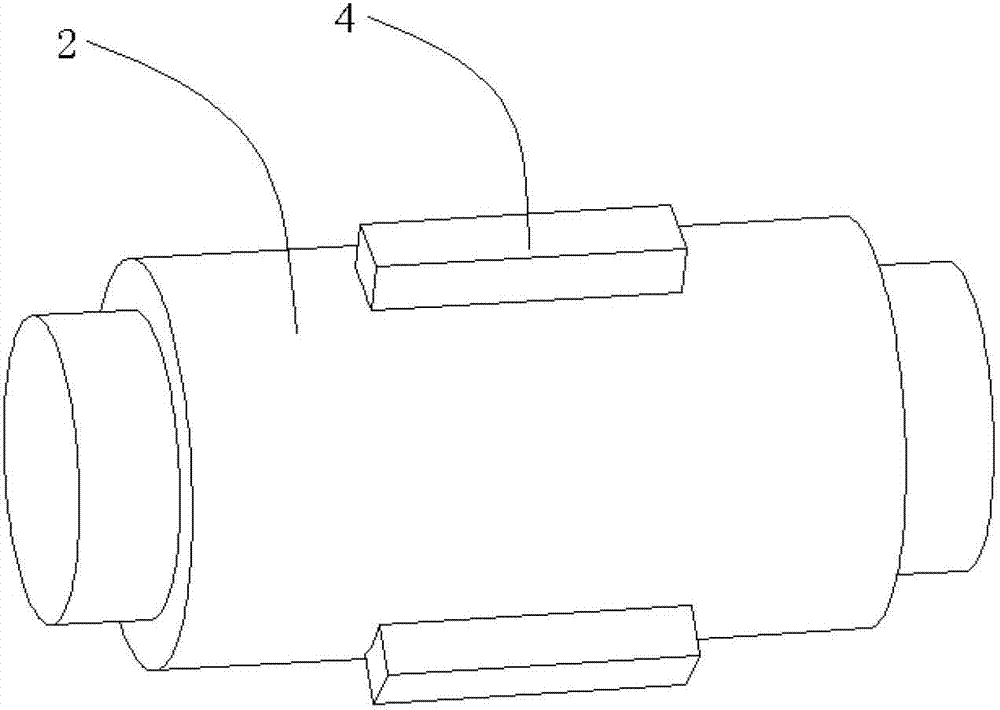

[0017] Combination roll with micro-structure flakes, including multiple ring flakes (1) with equal or different diameters and a rigid inner shaft (2), said ring flakes (1) can be edged unprocessed or processed Ring flakes of various geometric shapes, the unprocessed ring flakes of different diameters (1) can be assembled with the inner shaft to form a microstructure roller with circumferential grooves, or the ring flakes with the same diameter can be processed into various geometric shapes (1) form the required microstructure roller with the inner shaft, the rigid inner shaft (2) has fasteners (3) at both ends for positioning and fastening the ring sheet (1), the rigid The inner shaft (2) has more than one axial rib (4) in the axial direction, and the axial rib (4) can be integral or detachable metal ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap