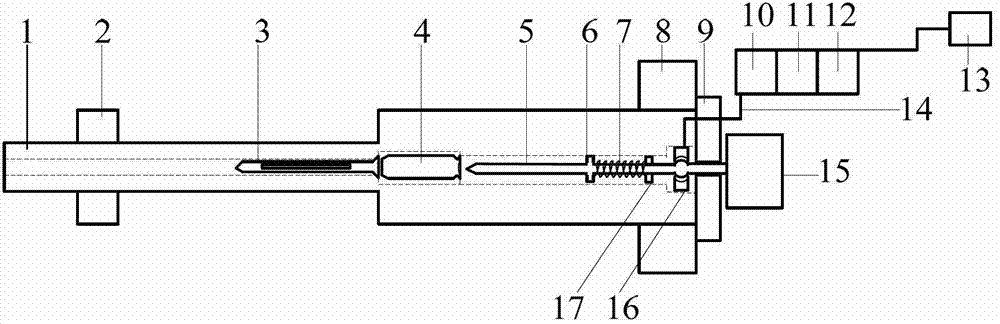

Remotely controlled continuous casting billet nail jet device and method

A technology of continuous casting billet and remote control, which is applied in the direction of casting equipment, indicating equipment/measurement equipment configuration, manufacturing tools, etc. Loss of casting slab, easy to carry on site, and the effect of ensuring personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

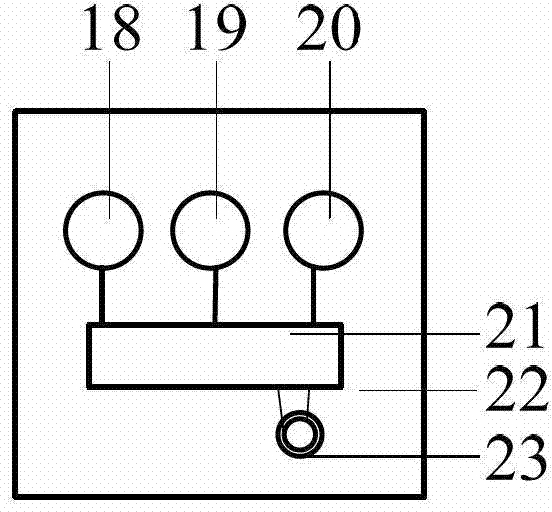

Method used

Image

Examples

Embodiment

[0015] Using the device and method of the present invention, the 200mm×200mm square slab of GCr15 bearing steel produced by a certain factory is used for online measurement of the continuous casting slab solidification thickness measurement. The steps are as follows: ①Make a measurement plan before nailing, and calculate the trigger time of the measurement point; ②Set The nail shooting device is fixed on the side of the continuous casting slab to be measured, and the guide hole on the front end of the nail shooting device is vertically aligned with the continuous casting slab measurement surface; ③Turn on the power of the nail shooting device five minutes before firing; ④Operation Evacuate the personnel and on-site personnel to a safe area; ⑤ Turn on the power switch of the remote control one minute before the start of firing, count down, and wait for the firing command; ⑥ When the firing time is reached, press the firing button on the remote control to fire the nailing device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com