Glass tube clamp

A technology of glass tubes and fixtures, which is applied in the field of fixtures and fixtures, can solve the problems of affecting assembly quality, glass tube scratches, and easy shaking, etc., and achieve the effects of improving assembly quality, preventing scratches, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

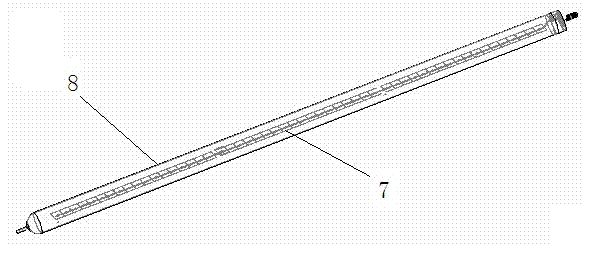

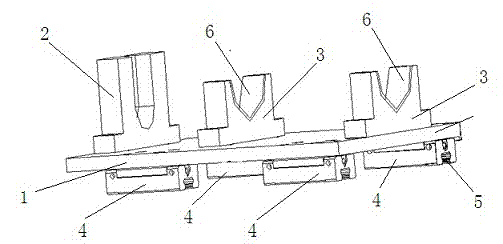

[0014] Such as figure 2 As shown, a glass tube fixture is used to drive such as figure 1 The shown glass tube 8 moves forward, which includes a fixture base plate 1, a baffle plate 2 is installed at one end of the fixture base plate 1, and the baffle plate 2 can withstand the rear end of the glass tube 8, and two interval distributions are fixed above the fixture base plate 1. One of the glass tube support blocks 3 is arranged on the other end of the fixture bottom plate 1, and the other is arranged in the middle of the fixture bottom plate 1. The two glass tube support blocks 3 and the baffle plate 2 are on a horizontal line, and the glass tube support block 3 is There is a groove 6 for placing the glass tube 8. The groove 6 is V-shaped, and the ends of both sides are bent upwards. A layer of protective pad is provided on the groove 6. The protective pad is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com