Composite fabricated part based on digital guide template and preparation method thereof

A composite material and prefabricated part technology is applied in the field of composite material prefabricated parts and their preparation based on digital oriented stencils. , the effect of increasing the fiber volume content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

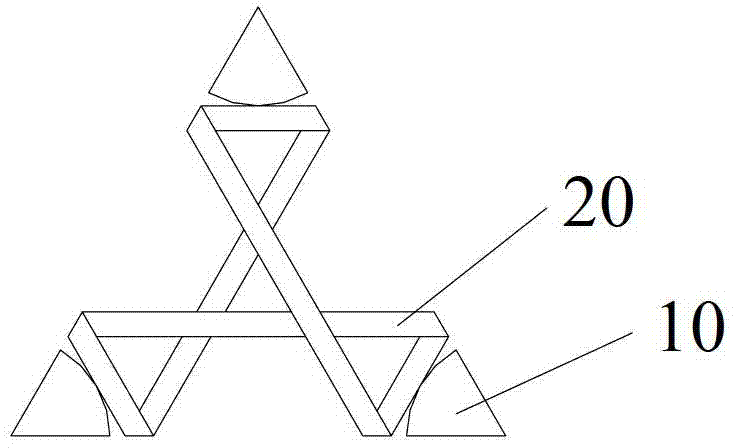

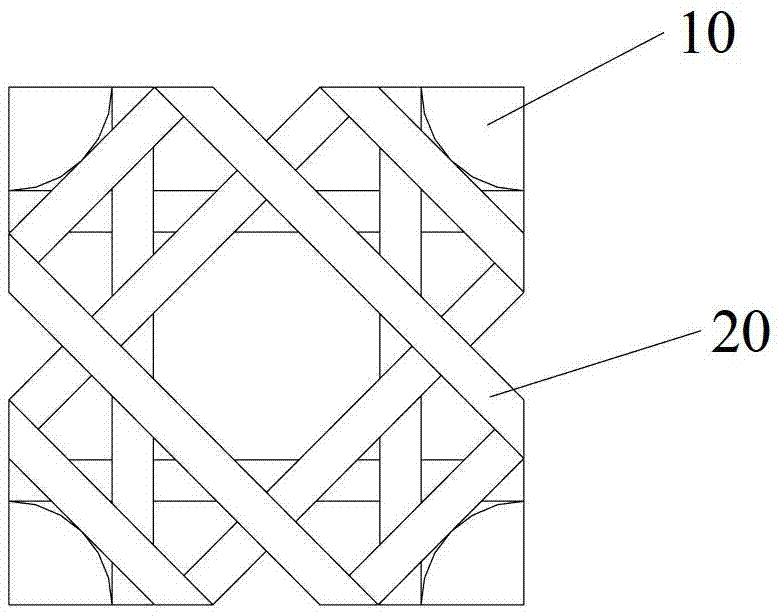

[0045] According to a typical embodiment of the present invention, a method for preparing a composite material preform is provided. The preparation method includes the following steps: fixing a plurality of guide sleeves 10 on a guide template according to a predetermined path to form a predetermined shape; passing and laying the fibers 20 along the gaps between the plurality of guide sleeves 10 to form a plurality of stacked laying layers, The belt surface of the fiber extends in the laying layer, and the extension direction of the guide sleeve intersects with the laying layer (that is, the fiber is laid and arranged between the guide sleeves 10); the fibers 20 wound between the multiple guide sleeves 10 are compacted, A composite material preform is obtained. With the application of the technical solution of the present invention, since the fibers are laid and wound in a plurality of guide sleeves, the thickness of the preform can be controlled according to the number of lay...

Embodiment

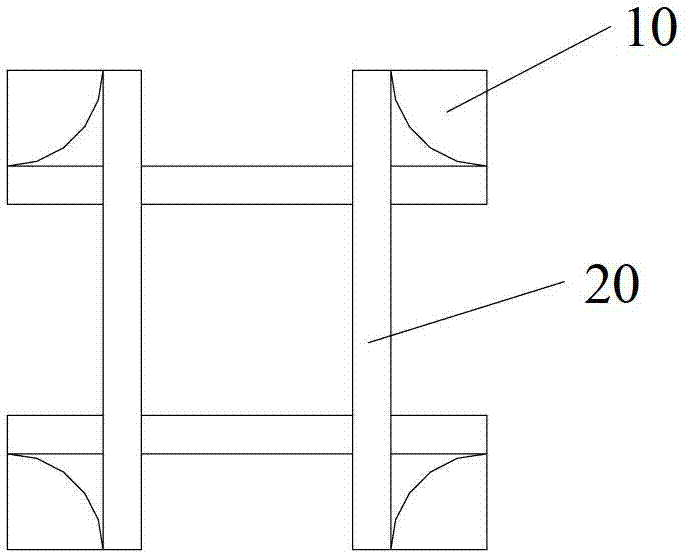

[0052] Utilize technical scheme of the present invention to manufacture a composite material T-beam prefabricated part, as Figure 8a and 8b As shown - the T-beam preform includes a beam portion 41 and a beam portion 42 . Specific steps are as follows:

[0053] 1) The T-beam prefabricated model is layered. Since its thickness is 40mm and the thickness of one layer of laying yarn is 1mm, it is divided into 40 layers.

[0054] 2) According to the appearance characteristics of the parts and the force characteristics of the T-beam, the laying angles are 90°, 180°, 45°, 135°, and the fiber yarn laying method of four layers is a cycle, that is, the quadrilateral laying path.

[0055] 3) Design the shape and size of the guide template according to the quadrilateral laying path and the size of the T-beam. The cross-section of the guide template is rectangular, and the size is 600×500mm. Design the guide sleeve arrangement holes in the middle of the guide template, and the hole spaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com