Dual-rudder multi-powder ship capable of braking

A multi-power and rudder technology, which is applied in ship propulsion, ship parts, ship construction, etc., can solve the problems that the ship's turnover capacity and throughput capacity are greatly affected, the ship cannot be accurately aligned, and it cannot move backwards and laterally. Improve the ship's turnover capacity and throughput capacity, fast turning speed, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

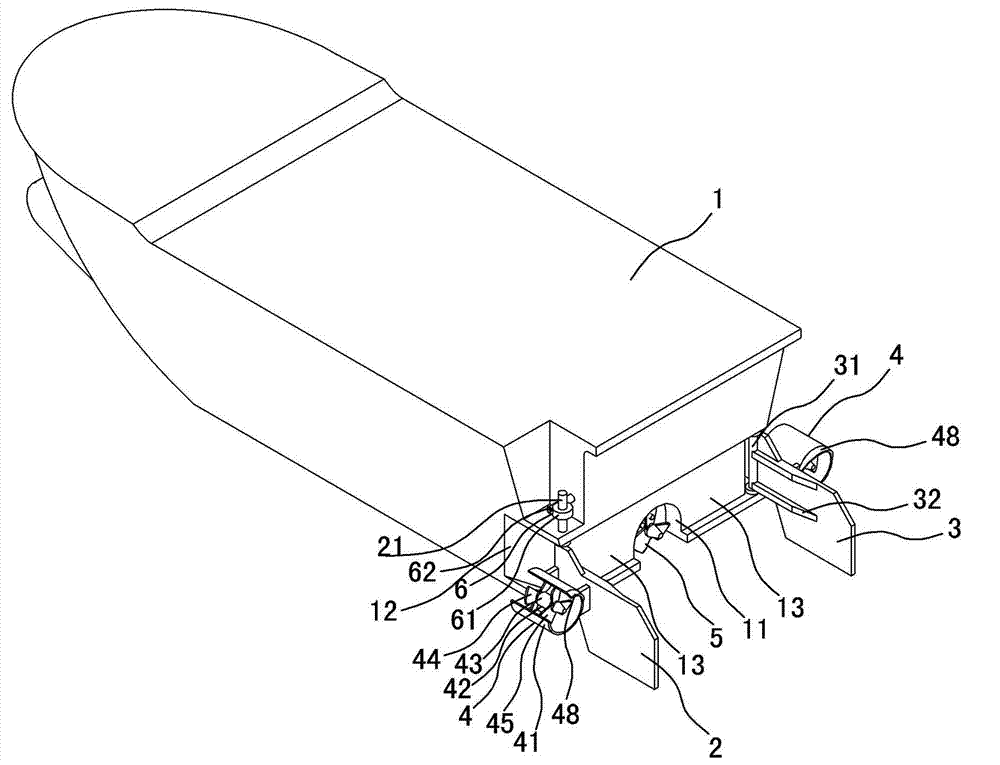

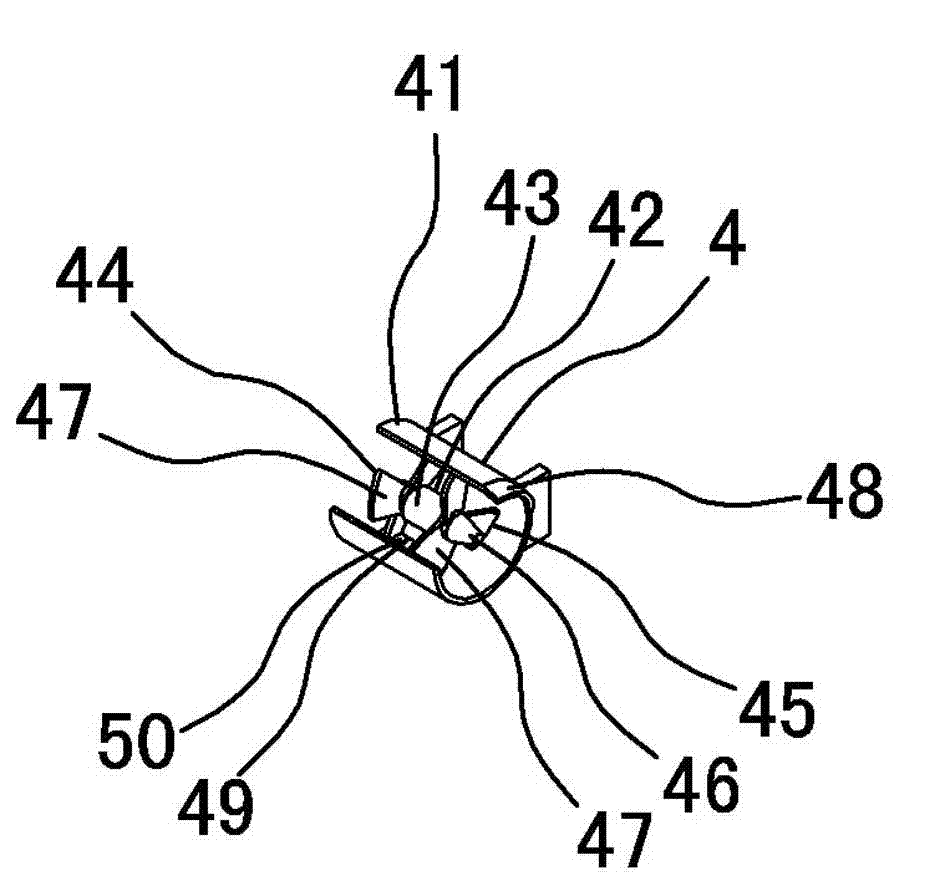

[0018] Such as figure 1 , figure 2 As shown, it includes a hull 1, the left and right sides of the rear of the hull 1 are respectively provided with a left rudder 2 and a right rudder 3, and the front sides of the left rudder 2 and the right rudder 3 are respectively provided with an axially erected rudder shaft 21 , 31, the left rudder rudder shaft 21 and the right rudder rudder shaft 31 are respectively rotated and installed in the left rear lower corner and the right rear lower corner position of the hull 1 underwater, and the upper ends of each rudder shaft 21, 31 penetrate in the hull 1 respectively Connected with the steering power mechanism, the left rudder 2 and the right rudder 3 are respectively equipped with a propulsion brake 4, the propulsion brake 4 is composed of a cylindrical shell 41 and a screw propeller 42 installed in the shell 41, the screw propeller 42 is made of a power machine 43 fixed in the housing 41 and a front propeller 44 and a rear propeller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com